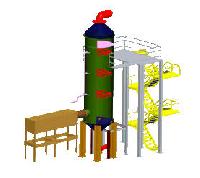

Fume Exhaust System

125,000 - 250,000 Per piece

1 Set (MOQ)

Fume Extractor Filter: Cleantek manufacturing fume Extarcor filter in various size and caapcity. The following filters made as per client requirements. Pre Filter Carbon Filter Spark arrester HEPA Filter

ESP Inner Arm Assembly

750 Per Piece

50 Piece (MOQ)

Best Deals from Industrial Scrubbers

Fume Extractors

Get Price Quote

How It WorksDynavac fume extraction systems consist of three basic parts: a capture point where fumes are captured, an airflow source to pull fumes through the system, and a filter system to remove the pollutants.Fume captureThe most efficient fume extraction systems remove the fumes as close as possible to their source. The best way to accomplish this is always dictated by the type of work being done : For tasks involving a small work area, such as hand soldering, the collection point can be situated extremely close to the source of the fumes, almost at the tip of the soldering iron. This is called Tip Extraction. For tasks that involve a larger working area, a higher volume fume extraction method must be used, consisting of hood or nozzle situated over the source of the fumes. This is called Volume Extraction. Airflow SourceThe airflow source for Dynavac fume extractors are centrifugal blowers. These blowers provide the required vacuum and airflow to draw the unhealthy fumes through the filtration system and exhaust the clean air.Filter SystemDepending on the type of application,our fume extraction system uses specially designed cartridge filter(s). These filters intake the fume and post filtration exhaust clean air.ApplicationDynavac fume extractors are source capture fume extractors. General applications include MIG welding, TIG welding, stainless steel pipe welding, spot welding, brazing, and more.Features Cleaner work environment: Reduces fumes and particulate making the workplace a healthier environment for the operator Dynavac fume extractors’ come with a cleanable.These filters can be cleaned with dry compressed air. Low noise level. The fume extraction system is supplied along with an articulated arm, which is flexible and enables optimum source capture of fumes. Highly portable: These machines are light and mobile, easy to move around. Low maintenance: Quick disassembly for cleaning and maintenance. Easy to access filter for cleaning. Economical to operate: Reduced energy consumption.

Fume Extractor

99,000 - 2,500,000 Per pc

1 Piece (MOQ)

Wet Scrubber

Get Price Quote

Wet Scrubber is manufactured by us to control sulfur emission released by the industries for e.g. in power generation plants using coal. All the dust and particles are removed by scrubbing by using limestone slurry to neutralize the sulfur dioxide produced in combustion process. The exhaust air forced is passed to remove fine water particles and also drop the dust. The water containing dust is treated with solid material and sent for recirculation. Specialty Modernized design Easy to install Easy to maintain Efficient performance Other Information Pay Mode Terms : L/C (Letter of Credit) Production Capacity : As per order Port of Dispatch : Any near port Delivery Time : 4 weeks Packaging Details : Poly propylene packing, wooden crate packing

Fume Extractor

Get Price Quote

1 Piece(s) (MOQ)

Overview: Dynavac���® manufactures a range of Fume Extractors to match the volume of fumesmoke that needs to be removed. Smoke during welding and other production processes flows in unexpected directions due to a variety of factors. Today, work related respiratory illnesses are increasing which results in lost work time as well as higher compensation costs for employers and numerous health related illnesses for employees. Dynavac���® Fume Extractors are portable systems designed for capturing and filtration of welding fumes in confined and other hard to reach spaces. Our fume extraction system offers reliable performance, quiet operation, optimal flow rates and adjustable self-supporting flexible extraction arms. FEATURES: 1.Cleaner work environment: Reduces fumes and particulate making the work place a healthier environment for the operator 2. Dynavac fume extractors come with a cleanable.These filters can be cleaned with dry compressed air. 3.Low noise level. 4.The fume extraction system is supplied along with an articulated arm, which is flexible and enables optimum source capture of fumes. 5.Highly portable: These machines are light and mobile, easy to move around. 6.Low maintenance: Quick disassembly for cleaning and maintenance. Easy to access filter for cleaning. 7.Economical to operate: Reduced energy consumption.

Wet Scrubber

Get Price Quote

UNICON Wet Scrubbers are used for removal of noxious and corrosive contaminants from the flue gases generated by various process in process plants. The gas is washed with suitable liquid medium using spray nozzles or atomizers. Suitable packed bed provides large contact surfaces for the gas and liquid to mix and hence traps the contaminants. Low pressure drop and low liquid flow brings down operating costs

Electrostatic Precipitator

Get Price Quote

Electrostatic Precipitator UNICON has a credential record of success in designing, engineering, fabricating, Supplying, erection and commissioning of electrostatic precipitator (ESP). To achieve this effectively, and to find out the solution for pollution problems by providing Electrostatic precipitators (ESP) for Power Plants upto 1000MW, UNICON entered into MoU for Transfer of latest technology, expertise, experience and favorable logistic support with M/s. Tianjie Group Co. Limited. Please Click Here to download our ESP Questionniare and to send Enquiry. Basic Working Principle of ESP In high- voltage electrostatic field, affected by the electric field force, gas ionization takes place. There are tremendous amount of electrons and ions existing in the ionized gas. After the dust particles are combined with these electrons and ions, they will be polarized, most of them are negatively polarized. Under the action of the field force, negatively charged particles migrates towards the positive electrode and in turn release electrons and attach to the positive electrode. When the particles agglomerate and the layers reaches a certain thickness on the plate, rapping system will start to work and the particles will be dislodged from the collecting plate by vibration and falling into the hopper. That ends the collection process. Special features of UNICON ESP: 1.Collecting electrodes are Cold roll formed with shape provided to ensure stiffness and to enhance rapping characteristics2.Individual Collecting electrodes are suspend from top to form a curtain. This also ensures that the Collecting system is not bulky and thus ensures good rapping characteristics. 3.Discharge electrodes are stretched spring coils of small lengths. This ensures that the straightness of electrodes are maintained easily and alignment of electrodes with respect to the collecting system is easily ensured.4.The spring tension also enhances the rapping characteristics of the electrode.5.This design of electrode ensures that no bending takes place. 6.The discharge electrode system is a rigid box frame structure. Ensuring rigidity and proper alignment of complete system. 7.The electrode system is so designed that approach to any level is possible for inspection and maintenance.8.Rapping system is the tumbling hammer type. Each electrode row is rapped individually. This has the advantage of low re-entrainment and effective rapping. Each rapping system can be tuned to rapping cycle suitable to the dust load handled by that field.9.Separate rapping is provided for each field. One for collecting electrodes rows and another for discharge electrode rows10.Electrode system is the PART of the electrostatic precipitator which decides its performance and reliability. 11.Support insulators of the discharge system are housed in individual insularor housings. These are provided with inspection covers, heaters and are fully sealed when closed making it air leak proof and also water leak proof. Ensuring that the Insulator surface is always clean.12.The individual insulators housings enables easy acess to each insulators for inspection and maintenance.13.Access doors are provided at inlet and outlet of each field, on hoppers and at the roof for easy access and maintenance.14. Safety interlock system is also provided for safety of maintenance and operation staff.15.Walkways and stairways are provided for easy approach to various equipments of the ESP.

acid fume scrubber

Get Price Quote

Wet Scrubber

Get Price Quote

We are offering wet scrubber. Features high collection efficiency of solid & gaseous pollutants maximum pressure drop fumes can also be absorbed low maintenance cost complete wetting of the product minimum product emission through exhaust ability to handle high temperature spray tower with specially designed high pressure nozzle mist eliminator to remove water droplets

dust scrubber

1,000,000 Per Piece

Wet Scrubber

Get Price Quote

As a quality-oriented organization, we are focused to provide our clients an excellent quality wet scrubbers. Our experts only use quality proven material while designing the offered wet scrubbers, in accordance with market standards of quality. The offered wet scrubbers are highly admired among customers for their trouble-free operation. Along with that, our wet scrubbers are provided in different specifications and can be customized on customer’s demand at highly affordable rates. FEATURES: Sturdy and compact Prevent pollution Eco friendly High performance Applications: Chemical industries, Fertilizer production and processing industries, Pulp and paper industries, Petrochemical industries, Pharmaceutical industries, Food and beverage industries, Electronics industries, Odor control, Steel making etc .,

Fume Extractor

Get Price Quote

An Industrial environment or workshop where such as composites, woods and plastics are machined must be embedded with Fume Extractor. There are various reasons which make Fume Extractor a must in such working environments: Health Reasons: Solvent fume exposure can lead to a range of respiratory illnesses; from asthma to more serious conditions. Legal Reasons: Many Governmental rules and regulations makes it compulsory for the owners to provide a safe, fume less or healthy environment for its workers and failing to do so can lead to penalties. Quality reasons: The Fumes negatively affects the machines or robotic arms degrading the quality of end products. Safety Reasons: Higher volumes of fumes can lead to a fire or explosion risk. CLEANTEK has been one of the most prominent manufacturer, supplier and exporter of the Industrial Cleaning Equipment. Established in the year 2004, CLEANTEK is highly appreciated for its quality of Fume Extractors. CLEANTEK is an ISO9001:2008 certified company. Fume Collectors manufactured at CLEANTEK are tested for various parameter like Power consumption, Construction, Performance, Durability, Finishing and Efficiency. Our Fume collectors are not just supplied to various states of India like Tamil Nadu but are even exported to many South Asian countries. Salient features: CLEANTEK Fume Extractors will reduce employee exposure to hazardous substances at minimal cost CLEANTEK provide high quality of packaging for safe transportation while supplying or exporting CLEANTEK has the easy to replace filter system and low cost maintenance CLEANTEK Fume Extractors efficiently remove odors and organic vapors

Wet Scrubber

Get Price Quote

GTS Enviro India Pvt Ltd is a leading supplier of wet scrubber machines in India, dedicated to providing top-notch industrial air pollution control systems. Our expertise extends to serving as a trusted manufacturer and supplier in Chennai, catering to industries such as foundries, boiler flue gas filtration, DG sets, metal finishing, powder coating, anodizing, the chemical and petrochemical sectors.

fume extraction systems

Get Price Quote

fume extraction systems, Paint Booth, Dust Collectors, Vacuum Cleaner

Fume Extractor

Get Price Quote

Fume Extractor, Industrial Vacuum Cleaners, Vacuum Table, Dust Collectors

Fume Extractors

Get Price Quote

Fume Extractors, Dust Collectors, dust extractors

Wet Scrubbers

Get Price Quote

We are among the acclaimed names in the industry for manufacturing and supplying Wet Scrubber. The offered scrubbers are used for removing dissolved gases and dust particles from air expelled from factories. These scrubbers are robust in terms of construction, resistant to corrosion and require least maintenance. The offered scrubbers are durable and available at cost-effective prices. Features: Robust design Non corrosive Low maintenance

dust scrubber

Get Price Quote

dust scrubber, Air Filters, Juice Heater, Cane Unloader Trolley

Fume Exhaust System

Get Price Quote

Fume Exhaust System, Air Blowers, Axial Fans