automation solutions

Get Price Quote

Barksdale is an ISO 9001 registered manufacturer of controls for industrial applications, specializing in the control and measurement of fluids. As a subsidiary of Crane Co., Stamford, CT, Barksdale have a manufacturing facility in Reichelsheim, Germany and distributors around the world. Barksdale components can be found in steel mills, on machine tools, in auto plants, in power generation and distribution facilities, in chemical processing plants, in pulp and paper mills, textile mills, amusement parks, and food processing plants, on offshore drilling rigs, in oil and natural gas fields, rescue equipment, and on many forms of transportation equipment, both on- and off-road. Many industries use a variety of Barksdale's product lines, In almost every industry, Barksdale products are at work, helping to build a better tomorrow

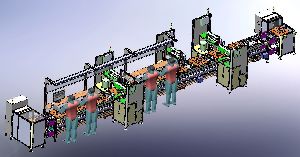

Assembly Line Automation Service

Get Price Quote

As a result of ever changing technology, more and more assembly lines are being automated. In order for an assembly line to be completely automated it requires the use of robots that perform tasks that would otherwise be done by people. If you were to see one in operation you may notice some things. The first thing you might notice is a group of workers standing close together. These workers will typically monitor and ensure proper operations of the fully automated assembly line. They make sure the robot equipment is working properly and fix any malfunctions. You may also see a conveyor belt moving items from station to station within the factory floor. This conveyor belt has no person directing its movements; instead, there is machine guidance and collision detection. Human workers are only required during final assembly and packaging stages. Before those steps begin, robots perform all functions related to welding, painting and car-body assembly as well as automated sorting and storage systems for parts storage. One of the main benefits is that they require less time to set up. Another benefit is that there are fewer errors made when working on an automated assembly line. Lastly, since many products have different sizes and shapes, humans would have more difficulty trying to figure out where each piece goes if it was an irregular shape or size

Looking for IT Solutions Service Providers

Sponge Iron Plant Automation

Get Price Quote

Sponge Iron Plant Automation, Core Shooter, Integration Testing Service

Process Simulation

Get Price Quote

Process Simulation

Automation Services

Get Price Quote

Automation Services

SOA Integration Services

Get Price Quote

SOA Integration Services, Spinning Production Monitoring System

landscape automation service

Get Price Quote

landscape automation service, Real Estate, Engineering Design Services

Dot Net Web Hosting

Get Price Quote

Dot Net Web Hosting, Open Source Ecommerce Solutions

Automation Service

Get Price Quote

Automation Service, auto air conditioning service

healthcare it solutions

Get Price Quote

healthcare it solutions, software applications

Third Party Integration Service

Get Price Quote

Third Party Integration Service, colleges, hospitals