Wheel Hoe Weeder

1,900 Per Piece

1 Piece(s) (MOQ)

the company is a well-known manufacturer, supplier and exporter of wheel hoe weeder. The range of wheel hoe weeder made available by us is designed using the best production techniques. Wheel hoe weeder is used to remove small weeds in dry land. The construction of wheel hoe weeder includes twin wheels, frame, v-blade with tyne, u clamp, scrappers and handles. Cutting and uprooting of weeds are done through push and pull action. Further, wheel hoe weeder is light in weight and pretty simple to operate. other information : f. O. B. Price order : 600 inr

...more

Wetland Weeder

1,800 Per Piece

We are main supplier of this product.

Brand Name : KSNM

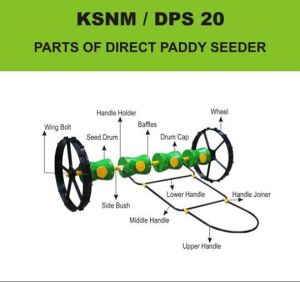

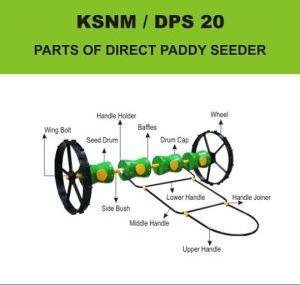

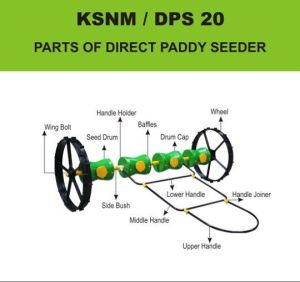

wetland seeder

4,800 Per Piece

1 Piece(s) (MOQ)

DIRECT PADDY SEEDER is one of the revolutionary equipment that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy.

Brand Name : KSNM

...more

Venturi Injector

480 Per Piece

1 Piece(s) (MOQ)

The company is a well-known Manufacturer, Supplier and Exporter of Venturi Tube. The range of Venturi Tube made available by us is manufactured using high quality materials and is hence quality assured. The company offers Venturi Tube at the best prices in the market. Venturi Tube is meant for fetigation in drip irrigation system. Also, it is made from engineering plastics-Virgin Nylon material. Venturi Tube includes ball valve, hose collar, one meter length hose and filter. Cost of KSNM Venturi : 480 INR

Type : Tube

Material : Plastics-Virgin Nylon Material

Application : Agriculture

...more

venturi

480 Per Piece

Venturi is menat for Fertilizer & Chemical injection through drip irrigation system Venturi - fertilizer injectors are the most efficient and economical way to feed liquid nutrients to the roots of the plants through drip irrigation system. Fertigation is being done simultaneously along with irrigation. Plants absorb fertilizer more efficiently when it is in liquid form. Easy to install. Economical and most efficient. Ensures regulated fertilizer injection. Manufactured with virgin plastic co-polymer material for durability. High quality material resistance to most of the chemical used in agriculture. Injectors deliver precise dosing, proportional to the system's flow rate based on water volume

Application : Agriculture

Brand Name : KSNM

...more

Uniformity Rice seeding machine

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering uniformity rice seeding machine. Direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

...more

Uniformity Rice seeding machine

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering uniformity rice seeding machine. Direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

...more

Uniformity Rice seeding machine

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering uniformity rice seeding machine. Direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

...more

Types of Irrigation System

2,600 Per Pack

1 Meter (MOQ)

For online shopping visit www.ksnmdrip.com( free shipping with in india) ksnm company introduction established in the year 2001 we are one of the eminent manufacturers of drip irrigation products. The factory is spread over one and half acre land at the base of western ghats and is surrounded by lush green environment. It's located in coimbatore, india. We possess a high roof build up area of 20,000 square feet and an advanced infrastructure that offers installed annual production capacity of 1500 tonnes of drip tapes.we are iso 9001:2008 company and continuously upgrade our technical competence to be a world class organization. Specifications: â�¢ drip lateral tape is a seamless tube. Â�¢ manufactured from special grade virgin poly ethylene mixture â�¢ uv stabilized for longer life when exposed to sunlight. Â�¢ drip tape is normally flat and becomes round shape when water passes through. Â�¢ water flows continuously through the drip hole like a jet instead of drop by drop. Â�¢ flexible tape makes it convenient for coiling and de coiling â�¢ recommended for closely spaced crops. Â�¢ drip tape is for above ground laying and cannot be used for sub-surface. Â�¢ drip tape is very simple and affordable by small farmers. Â�¢ it comes in roll packing of 1000 metre. ksnm drip tape 250 a) wall thickness â�� 250 micron. Size â�� 16 mm b) drip holes are formed in the tape with spacing of 45 cm, 60 cm, 75 cm, 90 cm. C) customer requirements of spacing and thickness can be manufactured against order d) drip tape discharge is approximately 10 liter per hour. advantages of ksnm drip tape 1. Low cost 2. No blockage of drip holes 3. Operates at low pressure 4. Easy to fold and unfold 5. Easy to install and maintain

Material : Special Grade Virgin Poly Ethylene

Thickness : 250 Micron

Length : 1000 Meters

Diameter : 16MM

Condition : New

Country of Origin : India

...more

tnau weeder

1,800 Per Piece

1 Piece(s) (MOQ)

Cono Weeder is suitable for Wetland weeding

Brand Name : KSNM

Application : Wetland Weeding

Condition : New

...more

tnau paddy seeder

4,800 Per Piece

1 Piece(s) (MOQ)

Salient Features : Labour cost is reduced drastically. Uniformity in seed sowing and plant population. Continuous drilling of seeds is eliminated. Reduction in seed rate and thinning cost. Crop matures 7-10 days earlier than transplanted paddy. Light in weight and easy to handle. An area of 1 hectare can be sown in a day.

Brand Name : KSNM

...more

TEE 40 mm Lock Adaptor

30 Per Piece

10 Piece(s) (MOQ)

Tee Connector / 40 mm Lock is used for Rain Hose Fittings.This connector can be used to irrigate "T" shaped fields.All three sides are 40 mm with Lock to connect Rain Hose / 40 mm.

Type : Irrigation Fitting

Material : PP

Color : Yellow

Feature : Corrosion Proof, Excellent Quality, Fine Finishing, High Strength, Highly Durable

Brand Name : KSNM

...more

Straight Connector / 40 mm Lock

18 Per Piece

10 Piece(s) (MOQ)

straight connector is used to join the rain hose / 40 mm, if there is a cut or damage. Visit www.ksnmdrip.com for product details and pricing.

Material : PP

Color : Yellow

Finishing : Polished

Line diameter : 40 mm

...more

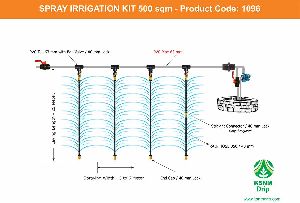

SPRAY IRRIGATION KIT - 500 Sqm

2,340 Per Pack

1 Pack(s) (MOQ)

Spray irrigation kit uses rain hose / 40 mm. This is a "do it yourself kit". no professional is required to install the kit. the kit contains all the parts required for spray irrigation of the given area expect pvc pipes. check out the following video: 1. Rain hose installation : https://youtu.be/luanqy2umty 2. Rain hose in onion field : https://youtu.be/yau8hcwmubw 3. Rain hose in groundnut field : https://youtu.be/bbdc_ijcst4

Brand Name : KSNM

Material : Plastic

Diameter : 40 Mm

Application : Spray Irrigation

Pressure : 1 Kg/cm2

Diameter : 40 mm

Color : Black

...more

SPRAY IRRIGATION KIT / 40 mm - 500 Sqm

2,400 Per Box

1 Box (MOQ)

this kit is for 500 sqm area ( 12 cents ). this can be purchased as sample kit. the spray irrigation kit uses rain hose / 40 mm. This is a "do it yourself kit". the kit contains all the parts required for spray irrigation of the given area. Only pvc pipes of 2 inch / 63 mm is required additionally. no professional is required to install the kit.

Diameter : 40 mm

Color : Black

Condition : New

Application : Irrigation

Brand Name : KSNM

...more

SPRAY IRRIGATION KIT / 40 mm- 1/4 acre

3,900 Per Piece

seeding machine

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering seeding machine. Direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

...more

seeding machine

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering seeding machine. Direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

...more

seeding machines

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering seeding machine. Direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

...more

seeding machine

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering seeding machine. Direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

...more

Seeder

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

...more

Seeder

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

...more

seed planter Machine

4,800 Per Piece

1 Piece(s) (MOQ)

We are offering seed planter machine. Direct paddy seeder direct paddy seeder is one of the revolutionary equipments that changed the face of sowing paddy seeds in wetland field. Direct paddy drum seeder has eliminated the need of transplantation and hours of manual work which will literally break the back of the farmers involved in sowing the paddy seeds to the field. At one stretch with single operator effort, it covers 8 rows of 20 cm row to row spacing at a time. Made up of plastic material, which makes it easy. Salient features labour cost is reduced drastically. uniformity in seed sowing and plant population. continuous drilling of seeds is eliminated. reduction in seed rate and thinning cost. crop matures 7-10 days earlier than transplanted paddy. light in weight and easy to handle. an area of 1 field preparation field must be well puddled and leveled. wate must be drained out atleast 24 hrs before sowing to form hardslurry pan of puddle soil. at the time of sowing, only paper thin of water should be maintained in the puddled field. water should be flooded to the puddled field once in three days after sowing and drained out immediately. this practice must be continued for 12 days. Thereafter depending upon the height of the seeding, water should be allowed to stand in the field. Operation procedure after assembling, fill the drums with pre-germinated seeds. Remember only two-third of the drum are to be filled at a time. close the mouth with the knob provided. pull the seeder manually at a normal walking speed (1 kmh) in the backward position as in the photo. the wheel impression in the first pass will server as a maker. in the second pass the wheel should pass on the same wheel impression of the previous pass to maintain the row-to-row spacing of 20 cm. occasionally watch the dropping of the seeds through the holes of the seeder . refill the drum when it reaches one fourth capacity. continue the seeding operation.

...more

row seeder

4,800 Per Piece

1 Piece(s) (MOQ)

Capitalizing on an efficient industrial network, our organization has made coalitions with numerous reputed logistics solution sources. Thus, we can ensure on time distribution of consignments. Along with a spacious warehouse, our efficient Warehouse Management System helps us in keeping a track of all the products. We stringently maintain inventory by recording warehouse transactions and delivery of goods.

...moreOpening Hours