Stainless Steel Castings

Get Price Quote

1 Piece (MOQ)

Gray Cast Iron Castings

92 Per Piece

1000 Piece (MOQ)

Best Deals from Metal Castings

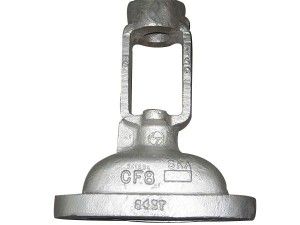

Alloy Housing Body

Get Price Quote

We are well-reckoned as one of the supreme Alloy Housing Body Exporters from India. Customers from all round the globe are placing repeated orders for the Housing Body due to applicability in Machinery Parts. Moreover, customers are eased with the availability of the Cast Aluminium Alloy Housing Body in varied sizes and dimensions as per the specifications provided.

ductile casting

Get Price Quote

Air Compressor Parts

15,000 - 150,000 Per Piece

10 pieces (MOQ)

Stainless Steel Casting

250 Per Kilogram

Steel Castings

120 - 180 Per Kilogram

10 Kilogram (MOQ)

cast steel casting

200 - 100,000 Per kgs

BALL VALVES, GLOBE VALVES, GATE VALVES, and other types of Steel Castings as per drawing specifications and our terms and conditions. All the transactions should be fully legal in nature. K Narayanan BSc. PGDMM. Global E-Governor(General)

Aluminium Pressure Die Casting

80 - 10,000 Per Piece

100 Piece(s) (MOQ)

Aluminium Die Cast Rotors for -Motors -Pumps & Rotational equipments

Casting

65 Per Kilogram

Expediting & Inspection Services. Pre Shipment Inspection in Supplier site. Pattern & Castings Inspection.

aluminium sand castings

Get Price Quote

Stern quality checks, frequent examinations and perfect packaging, we make certain that the range is as per the industrial standards. Located in Coimbatore(India), we have made our distinguished position in the market since our products are qualitative and of utmost standards.

Aluminium Casting

Get Price Quote

Audhe we’re a leading manufacturer and supplier of aluminium casting parts in India, who is engaged in design and produce aluminium alloy die casting, gravity casting, aluminium profiles, and CNC machining. We provide all-round production services from the design and development of mould to the forming and post-processing of casting products and surface treatment. The products are mainly used on 3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment and so on. With over more than 20 years’ experience in development and manufacture management, we can support the DFM report, mold flow analysis, and mold design service. Our company's production workshop consists of mould department, die-casting department, processing department, CNC department, paint department, etc. If needed, we can also make exporting die casting mold for customers. If you want to know more about our aluminium casting parts, aluminium dies casting products or other related products, please feel free to contact us.

Ductile Iron Castings

Get Price Quote

We are engaged in offering Ductile Iron Castings to various parts of the world. We offer Ductile Iron Castings that is manufactured using high-grade raw material and latest advanced technology in compliance with set industrial quality standards. Our Ductile Iron Castings are highly durable and have long functional life

SG Castings Borings

43 Per kgs

5000 Kgs (MOQ)

Centrifugal Casting

Get Price Quote

This process can be Sand Mouldegorized as similar to that of permanent mold method, Here as the molten metal is being poured, a permanent metal mold revolved about its axis at high speeds ranging from 300 to 3000 rpm. This can be in horizontal, vertical or inclined positions. As a result, the molten metal is centrifugally thrown towards the inside mold wall. There is solidifies after cooling. It’s usually a fine grain casting with a very fine-grained pouter diameter. Molds for Centrifugal castings can be divided into three types : The Permanent Mold: Made of steel, iron or graphite. Inside surface is coated with a thin refractory wash to increase mold life. The mold is preheated before coating, so as to dry the coating and improve the adherence to the mold surface. Rammed Mold: It consists of a steel metal flask, lined with a layer of refractory molding mix. The inside lining is coated with a refractory wash which is baked until dry and hard. Spun or Centrifugally Cast Mold: In the metal flask a predetermined mass of refractory materials in slurry form is poured.The flask on rotation makes the refractory materials centrifuged onto the wall of the flask. The rotation is stopped and the liquid portion of the slurry drained off. It leaves the mold with a refractory coating, to be baked until dry before use. Features of Centrifugal Casting : Castings can be made is almost any length, thickness and diameter. Different wall thicknesses can be produced from the same size mold Eliminated the need for cores. Resistant to atmospheric corrosion, a typical situation with pipes. Mechanical properties of centrifugal castings are excellent Only cylindrical shapes can be produced with this process. Size limited are up to 3m (10 feet) diameter and 15m(50 feet) length Wall thickness range from 2.5mm to 125 mm (0.1-5.0in) Tolerance Limit : On the OD can be 2.5 mm (0.1 in ) on the IS can be 3.8mm(0.15in) Surface finish ranges from 2.5 mm to 12.5 mm(0.1 -0.5in)rms AppliSand Mouldion :Typical materials that can be cast with this process are iron, steel, stainless steels and alloys of aluminium, copper and nickel. Two materials can be cast by introducing a second material during the process. Typical parts made by this process are pipes, boilers, pressure vessels, fly wheels, cylinder liners and other parts that are ax-symmetric. Type of Centrifugal Casting: Semi-Centrifugal Casting Centrifugin

Machined Aluminum Castings

5,000 Per Kilogram

hs code; 84099111.

aluminium sand castings

Get Price Quote

In order to gratify the needs of the clients, we engage in providing the finest quality of Aluminium Sand Castings at industry leading prices. We manufacture the Aluminium Sand Castings using the finest raw materials and modern tools under the strict supervision of skilled experts. The Aluminium Sand Castings are famous for having superior strength, majestic shine, and excellent finish. Our unique range of Aluminium Sand Castings is made up of the finest quality, and we guarantee 100% satisfaction to the buyers. Based in Coimbatore, Tamil Nadu, India, we are a leading manufacturer, exporter, and supplier of Aluminium Sand Castings.

Aluminium Gravity Die Castings

180 - 210 Per kgs

1000 Kilogram (MOQ)

Metal Castings

Get Price Quote

We are one of the prime Manufacturers and Suppliers of Metal Castings. At our end, Metal Castings are made using metal alloys for durability, high compressive strength, and resistance against corrosion. We have made Metal Castings available in different specifications and sizes to cater diverse demands of the customers.

Air Compressor Parts

Get Price Quote

All these Air Compressor Parts are designed using the finest quality material that is procured from reliable vendors of the market.

Carbon Steel Casting

Get Price Quote

Steel Castings are ideal for parts that endure wear, heavy loads, stronger than cast Iron & tough. The alloy elements added to alloy steel castings to obtain derivable chemical and mechanical properties. Heat treatment is essential for certain alloy steel castings for easy machining & increase wear resistance and remove hydrogen trapped at the surface of casting.

Chrome Alloy Casting

Get Price Quote

Stainless Steel Castings

Get Price Quote

Stainless castings are available for special applications Radiographed, Dye penetrant tested, Impact test and Microstructure tested as required.ASTM 351 : Grades CF3, CF3M, CF8, CF8M, , CF10, CF10M, CG3M,CG8M, CF8C,CN7M,CA6NM .

Cast Iron Die Casting

Get Price Quote

CI Castings

75 Per Kilogram

Steel Casting

Get Price Quote

We have available with us a durable range of steel castings which is manufactured using high grade raw material. These steel castings are corrosion resistant, possess excellent tensile strength and are used in various industries such as: Chemical Food & Beverage Products Petrochemical Pulp and Paper Equipment Power Generation Waste Treatment Available in standard as well as customized designs, these castings are offered at industry leading prices.

Aluminum Sand Casting

Get Price Quote

casting sand

Get Price Quote

In today’s manufacturing environment casting process simulation is the imperative tool that allows foundries to obtain reliable and high-quality cast parts. At Magna with MAGMASOFT software, we provide cutting-edge solutions that meet the needs of casting producers. Traditional trial-and-error approach are out dated and to be at the leading edge. Casting simulation is the standard accepted for designing the casting process before producing expensive moulds or patterns. Use of this casting simulation will keep casting producers competitive & profitable, in the sense they can provide precise & quick responses to customer needs.

bronze sand casting

Get Price Quote

We hold the expertise to offer a range of Bronze Sand Castings to our clients. These are made using optimum quality brass, bronze, phosphor bronze and allied material. To ensure flawless finished components, we make use of rolled metal, centrifugally cast or continuous cast. Furthermore, we also offer our product range as per the specifications given by the clients. Features: Durability Corrosion resistance High tensile strength Typical Applications: Machinery Valves and pumps Glass container moulds Marine hardware Electrical equipment like transformers, switchgear and connectors Industries Served: Glass bottle containers Turbo compressor Fluid control Defense Oil and gas Industrial air conditioning Railway Electrical

magnesium alloy die casting

5,000 Per Piece