Walling Stones

Walling stones yields an antique look to your homes and garden walls. It can enhance the looks of any type of constructions ranging from farm houses to commercial buildings. It is produced with the help of moulds designed in unique shapes like “tâ€. The moulds are tailor designed to display false joints, so that it appears to be made of several individual stones. It can be designed in number of shades according to the preferences in a particular region.

...more

ready mix concrete plant

Concrete Batching plant capacity 30m3hr with 4nos In-Line Bins and most advanced newly designed Planetary mixer and PLC based Panel of Command Alkon (USA) software. This ready mix concrete plant ensures complete homogeneous concrete quality with shorter cycle time. MEW 30 is most versatile cement concrete making plant for residential, commercial, Industrial, , Bridges, Road construction projects with many distinct features.

...more

ready mix concrete machine

Concrete Batching plant capacity 30m3hr with 4nos In-Line Bins and most advanced newly designed Planetary mixer and PLC based Panel of Command Alkon (USA) software. This ready mix concrete plant ensures complete homogeneous concrete quality with shorter cycle time. MEW 30 is most versatile cement concrete making plant for residential, commercial, Industrial, , Bridges, Road construction projects with many distinct features.

...more

Paver with out Facemix

It all started 2000 years ago when Romans introduced paved roads. They were rigid and strong to an extent that some of those pavers have been intact till today. Their interlocking structure yields high durability and strength as the interlocking units are held together by friction. The pavement stands as a composite structural unit and aids in weight transmission making it a choice when durability is our concern.

...more

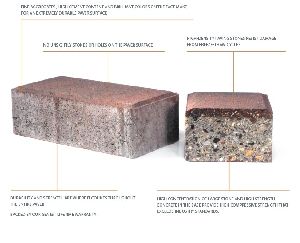

Paver with Facemix

Pavers are paving stones, which find application for exterior flooring. The base mix of high strength concrete when combined with a high concentration of stone yields paving stones with solid strength and durability. The face mix is usually a blend of fine aggregate, concentrated cement and a color pigment which provides a captivating look to the paver and also withstands scrapping. The coloring pigment is added only to the face mix and not to the base mix as the aesthetics of the base mix is unimportant as it is not exposed. Stuctural properties. Pavers with face-mix usually consist of two layers, the face mix which consists of the pigment and the base mix which is generally without any pigment. Generally face mix is about 7 to 10 millimeters thick which can withstand a lifetime of wear.

...more

paver plant machinery

Pavers are paving stones, which find application for exterior flooring. The base mix of high strength concrete when combined with a high concentration of stone yields paving stones with solid strength and durability. The face mix is usually a blend of fine aggregate, concentrated cement and a color pigment which provides a captivating look to the paver and also withstands scrapping. The coloring pigment is added only to the face mix and not to the base mix as the aesthetics of the base mix is unimportant as it is not exposed. Stuctural properties. Pavers with face-mix usually consist of two layers, the face mix which consists of the pigment and the base mix which is generally without any pigment. Generally face mix is about 7 to 10 millimeters thick which can withstand a lifetime of wear.

...more

Kerbstones

1. kerb stones are those robust designed stones used as divider in roads, parking lots and other industrial and commercial places. 2. High durability and strength of these stones makes it a most sought after option for roads.3. Less water absorbing properties necessitates less maintenance.4. Wide range of designs ensures the possibility of the stones be custom designed.5. High scrapping resistance makes replacement and maintenance a rare phenomenon.6. The good finish of the kerb stones not only adds aesthetics to the roads but also ensures safety to the pedestrians.7. Secondary processing can also provide different textures to the surface.

...more

Hollow Block Making Machine

As leading concrete block machines manufacturer in India, we not only produce quality machines but also provide expert guidance in setting up a concrete block making factory. Micro Engineering Works is a customer centric company with our prime focus being to exceed customer expectation.

...more

hollow block

Hollow blocks:- Hollow blocks are concrete blocks with hollow centers tailor designed with an objective to reduce weight. High density blocks can be produced by a combination of cement, sand and fine gravel, while low density blocks are produced by using fly ash as an alternative for the aggregate. Uses:- Structural performance of the walls is achieved when reinforcement bars are used either horizontally or vertically inside the blocks. Structural properties:- Ungrouted, partially grouted or grouted walls are the different structural reinforcements possible with these blocks. The grouted walls, being the most structurally strong type finds its application in seismic zones.

...more

Fly Ash Brick

Fly ash brick (FAB) is a building material, specifically masonry units, containing class C fly ash and water. Compressed at 28 MPa (272 atm) and cured for 24 hours in a 66 °C steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freeze-thaw cycles. Owing to the high concentration of calcium oxide in class C fly ash, the brick is described as "self-cementing". The manufacturing method saves energy, reduces mercury pollution, and costs 20% less than traditional clay brick manufacturing. The strength of fly ash brick manufactured with the above compositions is normally of the order of 7.5 N/mm2 to 10 N/mm2. Fly ash bricks are lighter and stronger than clay bricks.Main ingredients include fly ash, water, quicklime or lime sludge, cement, aluminum powder and gypsum. The block hardness is being achieved by cement strength, and instant curing mechanism by autoclaving. Gypsum acts as a long term strength gainer. The chemical reaction due to the aluminum paste provides AAC its distinct porous structure, lightness, and insulation properties, completely different compared to other lightweight concrete materials. The finished product is a lighter Block - less than 40% the weight of conventional Bricks, while providing the similar strengths. Machines available in 2 Variants 1. Pallet Type (Machine can be Customized).2. Belt Type (Machine can be Customized).

...more

designer tiles making machine

Power : 3 H.P (1.5 H.P Motor x 2 tables)

Concrete Mixing Plant

Concrete Batching plant capacity 30m3hr with 4nos In-Line Bins and most advanced newly designed Planetary mixer and PLC based Panel of Command Alkon (USA) software. This ready mix concrete plant ensures complete homogeneous concrete quality with shorter cycle time. MEW 30 is most versatile cement concrete making plant for residential, commercial, Industrial, , Bridges, Road construction projects with many distinct features.

...more

concrete block machine

Micro Engineering Works is a customer centric company with our prime focus being to exceed customer expectation. Our supreme experience in the art of making concrete block machines has molded us to be experts in trouble shooting and servicing machines.

...more

Concrete Batch Plant

Concrete Batching plant capacity 30m3hr with 4nos In-Line Bins and most advanced newly designed Planetary mixer and PLC based Panel of Command Alkon (USA) software. This ready mix concrete plant ensures complete homogeneous concrete quality with shorter cycle time. MEW 30 is most versatile cement concrete making plant for residential, commercial, Industrial, , Bridges, Road construction projects with many distinct features.

...more

Clay Brick Making Machine

Assisted by a qualified workforce and advanced manufacturing unit, we are engaged in offering a wide range of Clay Brick Making Machine that has 20000 bricks per shift production capacity. Offered machine is manufactured using high quality raw material and advanced manufacturing techniques under our expert's guidance. The offered machine is widely used for making clay bricks and is available in different capacities. Further, clients can avail this Clay Brick Making Machine from us at economical prices.

...more

clay brick machine

a qualified workforce and advanced manufacturing unit, we are engaged in offering a wide range of Clay Brick Making Machine that has 20000 bricks per shift production capacity. Offered machine is manufactured using high quality raw material and advanced manufacturing techniques under our expert's guidance. The offered machine is widely used for making clay bricks and is available in different capacities.

...more

Cement Block Making Machine

As leading concrete block machines manufacturer in India, we not only produce quality machines but also provide expert guidance in setting up a concrete block making factory.Micro Engineering Works is a customer centric company with our prime focus being to exceed customer expectation.

...more

Block Machines

As leading concrete block machines manufacturer in India, we not only produce quality machines but also provide expert guidance in setting up a concrete block making factory.VC

...more

Automatic clay brick making machine

Automatic Grade : Automatic

Power : 200 HP

Voltage : 415, 215

...more

Earthmoving Equipment

Industrial Strainers

Be first to Rate

Rate ThisOpening Hours