Vertical Pumps

Performance Data - Capacity – 500M3/Hr Temperature - Internal Bearing upto 100°C / External Bearing upto 350°C Pressure - 40 Bar Viscosity - Internal Bearing upto 10,000 Cst / External Bearing upto 1,00,000 Cst These pumps are available in standard foot mounted configuration with steam jacketing arrangement as an option.

...more

Rubber Lined Slurry Pumps

MATERIAL COMBINATIONS OFFEREDHichrome (28 % Cr, 600 - 650 BHN), Nihard & Rubber SALIENT FEATURES Greater wear life Closed / Open Impeller Tangential Discharge Casing Removable Suction & Rear Casing Liners Variable discharge nozzle positions Fixed / Variable speed drive Back Pull-out design OPERATING DATA Max.Working Pressure - 16 (bar) Max.Flow rate - 2500 rnVhr Max.Total Head - 100 mtr Max. Solid Size Dia - 126 mm Min/Max Speed - 720/960/1450 rpm Max. Temperature 180°c APPLICATIONS All Abrasive Slurries & Sludges Mineral & Ore Processing Cyclone Feed & Under-flow Tailings Disposal Lime & Clay Slurries Classifier & Thickener Under-flow Dewatering, Wash down & Sluicing High Density Slurries & Sludges Coal & Ash Slurries Beach (Sand) Recovery

...more

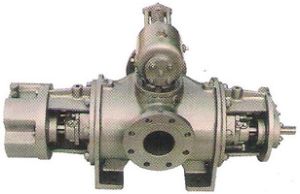

roto pumps

Performance Data - Capacity – 500M3/Hr Temperature - 350°C Pressure - 40 Bar Viscosity - upto 1,00,000 Cst These pumps are available in standard foot mounted & centre line mounted configuration with or without steam jacketing, sump heating, electrical / steam tracing arrangement as an option.

...more

Rice Milling Machine

Farming is the backbone of most countries in the world in including India. Technological advancements in agriculture has made farming a big industry. India is the world's second largest producer of rice after China. Improvements in the milling procedure of rice will highly benefit the farmer and the agricultural industry. We Navaka India an associate company of Gutta Engineers Pvt. Ltd. Kolkata understand the needs of the farmers. This wonderful machine has been introduced keeping the farmers in mind. This rice mill is a compact mechanical product newly developed and launched for the easy usage of every farmer. This rice mill is not only efficient but also environment friendly. It is a compact and efficient version of the traditional rice mill. The rice mill is available in two variants and is named SN-4.7 and SN-3.0.The SN-4.7 is an automatic version with a more powerful motor whereas the SN-3.0 is a self-sufficient economical version. The product is a substitute (or the big rice mill. It is not only compact but also portable and more cost efficient. It is simple to operate and no expertise is need for it. The milling can be done by simply pulling the feeding gate and turning the adjusting knob. The paddy is milled to polished rice, and the chaff is separated automatically. The hexagonal rice sieves and polishes the paddy or the brown rice by the process of mutual friction. The separated chaff can be used as fodder for cattle. The rice milled by this process is healthier as the nutrient content of the rice is preserved, as the Huller blade is not used. We have more products for agriculture and allied applications. Visit our website for the full range and details. The Importance of Rice Milling : Milling is a crucial step in the post production of rice. The basic objective of rice milling is to separate the husk and the bran, the end product being the white groins of rice. What Rice Milling gives :Most rice varieties are composed of approximately 20% rice husk 11% bran layers and 60% starchy endosperm also referred to as Total Milled Rice. In an ideal milling process this would result in the following fractions: 20%husk, 8-12% bran {depending on the milling degree) and 68-72% milled rice or white rice depending on the variety. The total milled rice contains whole grains or head-rice and broken. The byproducts in rice milling are rice husk, rice germ, bran layers and fine broken. PRODUCT CHARECTERISTICS Does husking, whitening and polishing of rice at the same time. Automatic controls and low loss rate of rice germ. Low noise and dust emission. Compact structure and ergonomic design, easy to assemble and move. Simple and easy to operate. Application after milling without reprocessing, application, individual operation by single person. Suitable for use in supermarket, food stores, individual households The rice that is milled is free of husk, stones.

...more

VisCompact Duo-Desk Dosing system

Characterizes an enhanced volumetric operating principle for an uninterrupted, pulsation-free and highly precise dosing process available with the new ViscoTec platform VisCompact Duo-Desk. The technology guarantees the system accuracy by its sophisticated dosing principle and eliminates the requirement of additional metering tools and complex closed loop control systems for the operation within the system specification.

...more

PULP PROCESS PUMPS

SS 316, SS 304, CI & Any other Alloys of Steel SALIENT FEATURES High Performance and efficiency Open Impeller Gland Packing / Mechanical Seals Standard Oil splash Lubrication Fixed / Variable speed drive Back Pull-out design OPERATING DATA Max. Working Pressure - 10 (bar) Max. Flow rate - 3000 mVhr Max. Total Head - 100 mtr Max Solid Size Dia - 95mm Min/Max Speed - 720/960/1450 rpm APPLICATIONS Food & beverage Industry De-watering & De-inking Liquors Corrosive & Non-corrosive liquors Chemical/Process Effluents Sugar Industries Power generation & Steel Handles Paper & Pulp stock, Consistencies - Upto 8 % Brewing & bottling plant Liquors

...more

preeflow automated dispensing systems

The dosing principle of preeflow® dispenser is an endless-piston dispenser.This special dosing geometry allows an endless and pulsation-free dosing flow. The possibility of reversing the dosing flow (suckback) will prevent dripping and leads to control of media stringing or dripping. Especially sensitive materials with high viscosity and fillers experience a gentle treatment due to the low shear stress and the low pressure.

...more

Horizontal Internal Bearing Pumps

Performance Data - Capacity - 500M3/Hr Temperature - 100°C Pressure - 40 Bar Viscosity - upto 10,000 Cst These pumps are available in standard foot mounted configuration with sump heating arrangement as an option.

...more

GENERAL REFINERY PUMPS

SALIENT FEATURES High Performance and efficiency Semi -Open Impeller Gland Packing / Mechanical Seals Standard Oil splash Lubrication Fixed / Variable speed drive Back pull out design Flange-ANSIB16.5 APPLICATIONS Handling Organic & Inorganic Chemical & Process Transfer General Refinery Services Erosive/Corrosive Liquors Demineralised Water Condensates OPERATING DATA Max. Working Pressure - 10/16 (bar) Max. Flow rate - 1000 mVhr Max. Total Head - 120 mtr Max Solid Size Dia - 50mm Min/Max Speed - 970/1480/2900rpm

...more

Flyer_adhesives

Rid your production of the problems caused by pressure and viscosity irregularities and prevent imprecise dosing which is an issue when dealing with difficult to handle materials.

...more

FlowPlus Sensor

The fluid sensor flowplus16 is a new development of ViscoTec Pumpen- u. Dosiertechnik GmbH. This sensor guarantees optimum process safety for almost all applications in which media is transported. flowplus16 can be used universally for the pressure measurement of fluids and other media in dosing applications.Via an intelligent software, the flowplus16 can analyze static and dynamic flow application mechanics

...more

Drum emptying system

The ViscoMT-XL barrel-emptying unit offers a modern solution for the emptying of containers.The use of RBL-series pumps for the emptying of medium offers the following advantages : container sizes starting from 50 l viscosities from approx. 80,000 to 2,000,000 mPas bridge frame with access for barrels on pallets very low shear stress of medium

...more

Chemical Process Pumps

The ECCV assures high performance with unmatched efficiency and increased reliability APPLICATIONS Non API 610 Chemical & Process Applications General Refinery Erosive / Corrosive Liquors ECPV PAPER / PULP & PROCESS PUMPSECPV is designed to deliver high performance with high efficiency and increased reliability, this series reduces maintenance cost and downtime. APPLICATIONS Food & beverage Industry Corrosive & Non Corrosive Effluents Sugar Industries ECHV HARD METAL SLURRY PUMPSThe ECHV is manufactured to retain high performance with highly abrasive erosive slurry and sludge handling capabilities. APPLICATIONS Power generation & Steel All abrasive slurries & sludges Mineral & Ore Processing Beach (Sand) Recovery & Dispersal Coal & Ash Slurries Metal waste separation / Recovery

...more

cartridge emptying system

The ViscoMT-C cartridge emptying system offers an industrial solution for the reliable emptying of cartridges. 310 ml Euro cartridges plunger piston without direct air cap material feed to dispensers deaeration capability after cartridge change electronic signal for „empty“ and „almost empty“

...more

VisCompact Duo-Desk Dosing system

Characterizes an enhanced volumetric operating principle for an uninterrupted, pulsation-free and highly precise dosing process available with the new ViscoTec platform VisCompact Duo-Desk. The technology guarantees the system accuracy by its sophisticated dosing principle and eliminates the requirement of additional metering tools and complex closed loop control systems for the operation within the system specification.

...more

Horizontal External Bearing Pumps

bentone burner

Be first to Rate

Rate ThisOpening Hours