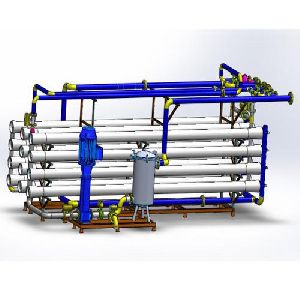

Reverse Osmosis Plant

100,000 Per Piece

1 Piece (MOQ)

Control Reverse Osmosis Plant

Get Price Quote

We bring forth highly advanced Zero Discharge Automatic PLC and Embedded control Reverse Osmosis Plant. Manufactured as per the globally accepted standards of hygienic design, engineering and manufacturing, the Zero Discharge Automated with PLC / Embedded control RO (reverse osmosis) Plants are perfect for ETP treatment. We take great care to ensure perfect design, quality, finish, traceability and also offer Customized plants. Made as per the principles of material science, biochemistry, fluid flow especially cleaning and sanitizing, the plant is highly demanded in the market. Advantages High levels of product consistency Welding and fabrication as per international standards Removes TDS from feed water Achieves 'Zero Discharge Reduces the demand for in-feed water as output is reused Application Areas Tannery Dyeing Dairy waste water Beverage industry

Best Deals from Osmosis Plant

Industrial Reverse Osmosis Plant

120,000 Per unit

1 unit (MOQ)

Reverse Osmosis Plant

Get Price Quote

1 Piece(s) (MOQ)

Gireesh Heat Exchangers & Cooling Towers is one of the prominent manufacturers, exporters and suppliers of a comprehensive range of industrial process equipment. Our range includes ro plant Cooling Towers, Heat Exchangers, agitator, pressure vessels, air cooled condenser, air receiver, filter vessels, industrial radiator, finned tube heat exchanger, U-bundle, Industrial Chillers,

Reverse Osmosis Treatment Plant

Get Price Quote

Reverse Osmosis The reverse osmosis treatment generally is applied to desalting of seawater and brackish water destined to human consumption, low pressure boiler feeding, feeding of ion exchange demineralization plants and other processing use.The aim of the treatment by inverse osmosis is reduction of 95 - 98% of dissolved salts and removal of bacterial charge from clear (filtered) water. The process of reverse osmosis is based on the peculiarity of half-permeable membranes, which water (or other solvents) is passing through, while molecules are retained as well as the ions of the dissolved solids. In normal conditions, when such a membrane is inserted between an aqueous solution and water, due to the pressure difference caused by difference on density the solvent is passing through the membrane to the solution (direct osmosis). The separation of the solvent from the solute can be obtained by means of large pressure difference due to the application on the more concentrated solution of a higher pressure than the pressure of the other side of the membrane (reverse osmosis). The velocity of solvent passage results to be much higher as higher is the pressure difference. Also many dissolved solids are diffused through the membranes in the lower concentration side. The process of reverse osmosis allows the water purification and dissolved solids concentration operations without any change in status and with a low consumption of energy. The separation process is obtained by means of a high pressure pumping of the dissolved solids solution to be treated; from membrane-type devices, called modules, two different flows under the influence of the pressure are obtained. The first flow (the orthogonal one) is passing through the membrane and at the outlet high reduction of salts and organic take place, while the second flow (the tangential one) is passing over the surface layer before the membrane. Two final results are obtained from the feeding flow through the system: the so called product (more diluted) and the concentrate. The performance of a reverse osmosis plant is related as first to the average capacity of product (the permeated flow) and to the concentrate (the rejected flow) of the membranes. Permeated flow and rejected flow are mostly due to the peculiarity of the used membranes (permeability to liquids, impermeability to solids), but at the same time they are also affected by the chemical and physical conditions of the process, such as pressure, temperature, pH, concentration and composition of the feeding solution. In other words the permeated flow:Increases (or decreases) according to the temperature and it is connected to the viscosity. The variation index changes according to different types of modules, and it is usually supplied in a table. If the temperature of the feeding solution changes frequently, it is often necessary to adjust the running conditions; this is a disadvantage for the manually adjusted plants. Increases if the running pressure increases: it not always convenient or possible to work at high temperatures; still, the pressure-resistance limits of the modules must be always taken into consideration. Decreases if the concentration of the feeding solution increases: however, unlike the temperature, the relation between the two cannot be generalized. Decreases over the time, due to progressive irreversible degradation of the membranes; when the permeated flow increases and its quality decreases, it means that the active layer of the membrane has been worn or oxidized. The quality of the permeated flow depends mainly on the rejection of the membranes: the rejection is sized through the ratio between the difference in concentration between feeding solution and permeated flow and the feeding solution concentration. The rejection factor is dimensioned usually with reference to a single component like sodium chloride. The rejection flow:Increases when the pressure increases, as this affects the difference between the velocity of water and the velocity of solids through the membranes. Slightly decreases when the temperature rises. Decreases over the time, due to the progressive surface fouling of the membranes it is affected by pH variation of the feeding solution. Generally little affected by variations of solids concentration, as long as such concentration does not increase remarkably near the surface of the membranes.The quality of the permeated flow does not depend only on the rejection: even if the rejection is constant, the concentration of the permeated flow could increase or decrease according to the concentration variations of the feeding solution. As inside the modules (especially if placed in series) the concentration increases gradually from the inlet to the outlet, the permeated flow will get progressively worse. It is therefore clear that the actual performances of the plant in terms of productivity and quality (concentration) of the parameters depend also on the recovery factor (or conversion factor). Such a factor describes the quantity ratio between permeated flow and feeding solution concentration. Whatever deviation of the recovery factor from the fixed value, due to either a specific decision of the operator or external reasons, will always produce variations in the quality of the permeated flow. Although the flow is steady, an eventual worsening of the quality of the permeated flow (which is immediately recognized by an increase in the conductivity), can be due to variations in the concentration of the feeding solution concentration or in the recovery factor. These two causes are easy to detect and correct, but if worsening in quality depends on problems of fouling or chemical damage of the membranes, nothing can be done to solve the problem.

Reverse Osmosis Plant

Get Price Quote

Reverse osmosis (RO) is a water purification technology that uses a semipermeable membrane. This membrane technology is not properly a filtration method. In reverse osmosis, an applied pressure is used to overcome osmotic pressure, a colligative property, that is driven by chemical potential, a thermodynamic parameter. Reverse osmosis can remove many types of molecules and ions from solutions, and is used in both industrial processes and the production of potable water. The result is that the solute is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side. To be "selective", this membrane should not allow large molecules or ions through the pores (holes), but should allow smaller components of the solution (such as the solvent) to pass freely.

Reverse Osmosis Water Treatment Plant

Get Price Quote

The Reverse Osmosis Water Treatment Plant removes around 90 to 98% of total dissolved salts from the water and thus it plays an important role in the field of water purification. The company is an eminent Reverse Osmosis Water Treatment Plant Manufacturer and Supplier in India. The Reverse Osmosis Water Treatment Plant can be availed from us at the market leading prices.Applications : To get pure, protected drinking water in houses, apartments, residential colonies, hospitals, clinics, restaurants, hotels, industries, schools, colleges, etc. Process water for manufacturing plants and Boiler feed Water Beverage and Food processing industry Mineral Water and Pharma Industry Haemodialysis Application : As a pretreatment system before Demineraliser Plant to save Cost on Control. Removal of Nitrates, Arsenic, Fluoride and other contamination from Drinking Water Reverse Osmosis :Reverse osmosis is the process of forcing a solvent from a region of high solute concentration through a membrane to a region of low solute concentration by applying a pressure in excess of the osmotic pressure. This is the reverse of the normal osmosis process, which is the natural movement of solvent from an area of low solute concentration, through a membrane, to an area of high solute concentration when no external pressure is applied. The membrane here is semi permeable, meaning it allows the passage of solvent but not of solute.To illustrate, imagine a semi permeable membrane with fresh water on one side and a concentrated aqueous solution on the other side. If normal osmosis takes place, the fresh water will cross the membrane to dilute the concentrated solution. In reverse osmosis, pressure is exerted on the side with the concentrated solution to force the water molecules across the membrane to the fresh water side. The membranes used for reverse osmosis have a dense polymer barrier layer in which separation takes place. Since Reverse Osmosis does not occur naturally, it must be created by applying pressure to the high solids water in order to force it through the membrane, with pressures from 8 - 14 bar for fresh and brackish water, and 40 - 70 bar for seawater, which has around 24 bar (350 psi) natural osmotic pressure which must be overcome.

Reverse Osmosis Plant

110,000 Per Piece

Reverse Osmosis Plants

Get Price Quote

1 Piece(s) (MOQ)

We are offering reverse osmosis plants. Blueberry automatic ro plant 12liter capacity.

Reverse Osmosis Plant

200,000 Per Piece

Reverse Osmosis Plants

Get Price Quote

Reverse Osmosis Plant

Get Price Quote

CCTV Camera, Mobile DVR, Biometric Fingerprint Reader

Reverse Osmosis Plant

Get Price Quote

Reverse Osmosis Water Plant

Reverse Osmosis Plants

Get Price Quote

water lifting pumps, pressure boosting, hvac test equipment, fire fighting

Reverse Osmosis Water Plant

Get Price Quote

Reverse Osmosis Water Plant, Mineral Water, Mineral Water

Reverse Osmosis Plant

Get Price Quote

Water Purifier

Reverse Osmosis Plant

Get Price Quote

Reverse Osmosis Plants

Get Price Quote

Demineralization Plants, sewage water treatment, iron Removal Plants

Reverse Osmosis Plant

Get Price Quote

Desktop Computers, Uninterrupted Power Supply

Reverse Osmosis Plant

Get Price Quote

strech wrapping packing machine

Reverse Osmosis Plants

Get Price Quote

Reverse Osmosis Plant

Get Price Quote

reverse osmosis spare, Textile Softeners

Reverse Osmosis Plant

Get Price Quote

Aluminum Frame, Reverse Osmosis Water, ss mosquito nets

Reverse Osmosis Plant

Get Price Quote

Reverse Osmosis Plant

Get Price Quote

Reverse Osmosis Plant

Get Price Quote

Industrial Water Softeners

Reverse Osmosis Water Treatment Plant

Get Price Quote

Reverse Osmosis Water Treatment Plant, Solar Generator