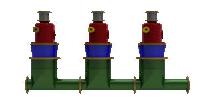

Powder conveying system

125,000 - 600,000 Per Piece

1 Piece(s) (MOQ)

Pneumatic Conveying System for Flour

Get Price Quote

1 Piece (MOQ)

Pneumatic conveying presents many advantages that make it a good choice for transporting powders such as flours: it can reach high capacity, can convey over relatively long distances and with a flexible pipe layout, allows to contain well the dust. In a pneumatic conveying system, The powder is diluted by the air which means that the ratio (kg product/kg air) is relatively low. air is blown on one side of the process and the powder air mixture flows in conveying pipes until the its final destination. The product is transported in the form of a cloud in the conveying pipes. Features: DUST FREE: Material can be drawn directly from drums, Bags, storage containers, process. vessels- no messy dumping or manhandling. Charging of powder directly into closed vessels, including those under vacuum or pressure, preventing the formation of dust. Fully automatic system, with timing controls and automatic air blow back system for filter cleaning. Vacuum Blower and cyclone filter can be installed in out side production area. Advantages: Avoids product waste, loss and contamination. Minimal or No tools required to disassemble the unit · Low footprint . Filtration surface in function of the application

Best Deals from Pneumatic Conveying System

Pneumatic Conveying Systems

Get Price Quote

pneumatic systems

Get Price Quote

We offer Gymenma Sylvestre Extract. Our respected firm is widely applauded in the industry for providing a comprehensive collection of Pneumatic Systems

Pneumatic Conveying Systems

Get Price Quote

UNICON and its forerunner companies have been designing, manufacturing, supplying and erecting pneumatic conveying system for many years. Our installations have enabled our customers to operate their facilities in compliance with regulatory standards to achieve clean air environmental friendly emissions and effective utilization of Fly Ash. Principle of operation Stage 1 : Filling Ash inlet is at open position, ash from hopper storage is filled inside the vessel. Stage 2 : Fluidizing When ash is filled up to the level sensor probe, Ash inlet valve will be closed. Once fluidizing valve opens and fluidizes the ash and is ready to transport. Stage 3: Transmitting Discharge valve opens and the fluidized air with ash is transmitted through the pipeline. Stage 4 : Depressurizing Ash inside the vessel is emptied, the vessel is depressurized and the fluidizing valve closes, again the process is repeated from stage 1. the pressurized vessels feed to the conveying line, the automated control system maintains a constant conveying air mass flow in the pipeline, which prevents plugging and optimizes compressor operating power. Feeder units feed the line however in these system, material flows into the conveying line before the line is pressurized. It is a practical alternative for a vaccum system where headroom is limited. This approach, blending the most efficient flow regimes offers advantages in reliability and reduced maintenance costs that can keep the system operating more efficiently. Challanges of ash handling system Indian Coal presents high ash content generally which tends to be inconsistent. Design of the system has to adequately cover anticipated variations and be capable of handling the worst scenario. System has to be environment friendly. System has to be reliable with least maintenance problems System has to be energy efficient. Advantages UNICON Pneumatic Conveying Systems Commercial utilization of ash in - Cement additives - Brick plants. - Road making etc Saving of water - a precious commodity. Energy Efficient. Most Economical High Capacity Conveying Line High reliability. Long Plant life. Least maintenance. Conveying distance upto 1600 meters Environment concern. Wide range of vessel sizes Operating pressure upto 60psi (415 kpa) Shortest delivery time Programmable Logical Controller (PLC) Better control of pneumatic conveying system whose advantages are given below. 1. Most preferable type of control. 2. Ability to perform relay logic, timing, counting and sequencing functions. 3. performs the tasks required for pneumatic conveying system control. 4. Performs all ash handling controls. 5. Allows flexibility in control schems 6. Ability to troubleshoot, modify and expand with the system.

pneumatic systems

Get Price Quote

Obtain the extensive array of products from our well-established inventory located in Coimbatore(India). Dedicated towards bringing forth the finest and premium quality pneumatic systems, we are a well-established Supplier in this domain.

Pneumatic Conveying System

Get Price Quote

a pneumatic conveying system transfers powders, granules, and other dry bulk materials through an enclosed horizontal or vertical conveying line. By controlling the pressure or vacuum and the airflow inside the conveying line, the system can successfully convey materials. pneumatic conveying system can be configured with bends to fit around existing equipment, giving it more flexibility than a mechanical conveyor with its typically straight conveying path. since 2004, cleantek has been supplying its customers with highest quality of pneumatic conveying system for a wide range of industries. cleantek has been manufacturing pneumatic conveying system for the conveyance in: food industry pharmacy industry cement industry aluminum plants chemicals and fertilizers plastic processing industry port operations cleantek has become a prominent name in manufacturing, supplying and exporting industrial cleaning equipment in the period of few years because of the quality of products we manufacture are available at the least possible expense without any compromise in the quality. Our pneumatic conveying system are stringently tested on various parameters in order to ensure superior quality standards. Salient features of cleantek pneumatic conveying system: best quality of raw material is used to make the product contamination free designed as per the industrial norm for safe use easy to use and user friendly handling most effective for fast transfer

Pneumatic Conveying Systems

Get Price Quote

We are offering pneumatic conveying systems. Unicon and its forerunner companies have been designing, manufacturing, supplying and erecting pneumatic conveying system for many years. Our installations have enabled our customers to operate their facilities in compliance with regulatory standards to achieve clean air environmental friendly emissions and effective utilization of fly ash.

Pneumatic Transporter

Get Price Quote

Specifications Pneumatic Transporter Pneumatic Transporter is a true dense-phase pneumatic conveying system which, by virtue of its unique design, can transport sand or other bulk free flowing materials in a dense mass at low velocity, without the aid of boosters. A major part of the design of any pneumatic transporter is the vessel sealing mechanism. Unique design Vessel sealing mechanism A true dense phase

pneumatic control systems

Get Price Quote

Pneumatic Conveying System

Get Price Quote

Pneumatic Conveying System, Vacuum Cleaner, Pneumatic Conveying Blowers

pneumatic systems

Get Price Quote

pneumatic systems, embedded systems

Pneumatic Conveying Systems

Get Price Quote

We are the one of the reputed traders and suppliers of Pneumatic Conveying Systems

Legris Pneumatic Piping Systems

Get Price Quote

Legris Pneumatic Piping Systems, rubber band cutting machine

Pneumatic Conveying System

Get Price Quote

Pneumatic Conveying System, vacuum loaders, Vacuum Loading System

Hydro Pneumatic Booster System

Get Price Quote

Hydro Pneumatic Booster System

pneumatic systems

Get Price Quote

pneumatic systems, Machinery Tools and Parts

pneumatic control systems

Get Price Quote

pneumatic control systems, Air Cylinders, Pressure Control Valves

Pneumatic Conveying System

Get Price Quote

Pneumatic Conveying System, Vacuum Table, textile vacuum cleaner, Blowers

auto pneumatic systems

Get Price Quote

auto pneumatic systems, Leak Testing Machine 01

Pneumatic System

Get Price Quote

Pneumatic System, Pneumatic Fitting, Hose clip, Steel Ball

pneumatic systems

Get Price Quote

pneumatic systems, Hydraulic Forming Press