Pneumatic Conveying Systems

Get Price Quote

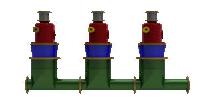

Pneumatic Conveying Systems

Get Price Quote

We are offering pneumatic conveying systems. Unicon and its forerunner companies have been designing, manufacturing, supplying and erecting pneumatic conveying system for many years. Our installations have enabled our customers to operate their facilities in compliance with regulatory standards to achieve clean air environmental friendly emissions and effective utilization of fly ash.

Best Deals from Pneumatic Conveyors

Powder conveying system

125,000 - 600,000 Per Piece

1 Piece(s) (MOQ)

Pneumatic Conveyor

Get Price Quote

Features: Unique modular design with High Performance Units easily dismantled and cleaned Suitable for all material transfer applications Superior filter technology for vacuum conveying with different designs available. Individual custom built adaptations to fit the specific application Vacuum Conveyors available for safe use with hazardous materials and environments. Highly effective High Pressure Vacuum Pumps No heat emission Advantages: Vacuum conveyors will ensure a dust free material transfer which is gentle on the material. There is little need for maintenance Almost no wear in the entire process These Vacuum Conveyors are simple to install and control When conveying powder there is no compacting of the powder inside the conveyor and the product is easily discharged. The Vacuum Conveyors are lightweight and compact Quiet and reliable operation System Types: Positive pressure System Vacuum conveying System Components of Vacuum conveyor: Material Receivers Material Pick Equipment Vacuum pumps Filtration System Material Discharge Valve Control Valve. Material Receivers: All Standard Vacuum Conveyor Material Receivers are In SS-304,SS316&M.S CR, The Vacuum conveyors units working series of fil/Dump cycles which are controlled by PLC unit.

Pneumatic Conveying System

Get Price Quote

a pneumatic conveying system transfers powders, granules, and other dry bulk materials through an enclosed horizontal or vertical conveying line. By controlling the pressure or vacuum and the airflow inside the conveying line, the system can successfully convey materials. pneumatic conveying system can be configured with bends to fit around existing equipment, giving it more flexibility than a mechanical conveyor with its typically straight conveying path. since 2004, cleantek has been supplying its customers with highest quality of pneumatic conveying system for a wide range of industries. cleantek has been manufacturing pneumatic conveying system for the conveyance in: food industry pharmacy industry cement industry aluminum plants chemicals and fertilizers plastic processing industry port operations cleantek has become a prominent name in manufacturing, supplying and exporting industrial cleaning equipment in the period of few years because of the quality of products we manufacture are available at the least possible expense without any compromise in the quality. Our pneumatic conveying system are stringently tested on various parameters in order to ensure superior quality standards. Salient features of cleantek pneumatic conveying system: best quality of raw material is used to make the product contamination free designed as per the industrial norm for safe use easy to use and user friendly handling most effective for fast transfer

Vacuum Conveyors

Get Price Quote

Vacuum Conveyors, packing machines, Roasting Machine, Blending Machine

Pneumatic Conveying Systems

Get Price Quote

We are the one of the reputed traders and suppliers of Pneumatic Conveying Systems

Food Vacuum Conveyors

Get Price Quote

Food Vacuum Conveyors, SS Slat Chain Conveyor, stainless steel slat conveyor