Weigh Feeder

Overview: Movement of bulk material is an essential feature in modern industrial processes. The simplest and fastest mode of transportation of such material is to convey them over a moving belt. In this operation the precise weighing of material, as it moves, has assumed a key role in process industries. Hence weigh feeder is a closed loop control system in which a precise control can be had over the flow of materials, which has indicating, totalizing and controlling instruments and circuits. The Weigh Feeder is a custom engineered equipment that finds application in continuous bulk proportioning of solids. This gravimetric feeder is operated by a closed loop control system enabling feeding at a controlled rate and exercises precise control over rate of flow based on a micro controller. The system is capable of accepting external signals from other controllers or from the process computer, depending on the extent of plant instrumentation. These gravimetric feeders are in operation in steel, cement, fertilizer and chemical industries. Each system consists of control and local panels, load cells to measure the instantaneous load, a digital tacho to sense the speed of the belt and a belt feeder conveyor shaft is driven by an AC motor coupled through the gear box.

...more

Vibration Transmitter

Overview: During the operating life, rotating machines suffers gradual deterioration in their condition and performance due to wear and tear caused by friction between moving parts on the machines. Increase in machine wear is always accompanied by increase in vibration level, which therefore can be used as index of machine condition. If the machine is allowed to run on without corrective measures being taken, vibration levels will increase with time at increasing rate until a stage is reached where the machine fails completely. Monitoring vibration levels on machines such as Fans, Blowers, Pumps, Cooling Towers and Turbines which has to be operated continuously will help to detect increase in vibration levels that are likely to result in machine failure, so that a programmed shut down may be carried out for maintenance. PG701 series of Vibration Transmitters are designed to monitor the vibration levels of the above mentioned rotating machines. The 4-20Ma signal being proportional to the “G” level can be connected directly to the monitoring device such as a PLC, else customized display devices & data logging system, can be provided by us.

...more

Vibration Switch

Overview: Vibration switch does the function of a “watch dog”. Certain amount of vibration is allowed in all the systems / Products. Vibration beyond a limit is catastrophic. This device monitors the vibration level of a machine, system and switches off / alarm, if its vibration goes out of the set limit. This can prevent unscheduled break downs for various heavy machinery such as large motors, gear boxes, cooling tower fans, etc. PreethiTech Vibration Switch consist of • Accelerometer with a frequency range of 10 Hz to 10 KHz giving an output proportional to acceleration.• A level setting circuit, to set the allowable level of acceleration.• A relay output, when the vibration exceeds the set level. This relay output can give warning or can shut the equipment under consideration.

...more

Vibration Meter

Overview: Vibration meter type VM301A0 is a portable instrument, which is used in conjunction with Piezo-electric accelerometers to measure mechanical vibrations in terms of acceleration, velocity & displacement. It is suitable for both laboratory and field conditions. This instrument can be used to monitor vibration levels in production machines on a periodic basis, so that action can be taken before a complete machine failure. Its operation is simple and quite suitable for use by non-scientific personnel not conversant with electronic instrumentation. In combination with PreethiTech Piezo electric accelerometers the unit provides direct read out of vibration parameters on a 3½ digit LCD display. The unit is pow

...more

universal shear load cell

Overview: The universal shear loadcell is generally used for material testing and in applications where both compression and tension loads are to be monitored. Applications: Bag Filling, Hopper Weighing Systems, UTM & Testing applications, Electro Mechanical Weigh Bridges.

...more

Tyre Inflator

Overview: Tyre inflators, also known as tyre pressure controller are the latest product that we have launched into the market. The systems are very rugged and can handle very hostile environments. The intelligent software ensures that the type of tyre is sensed and the filling happens in the shortest possible time. We have two models to suit your budget and operation which are the wall mounted model and the floor mounted model. these can be customized for special areas like cargo companies, military, police etc where the type of trucks are limited and so the tyre pressure need not be entered into the machine but the type of truck can be selected very easily. Our tyre inflators are ideally suited for fuel filling stations, automobile workshops, tyre shops, bus stations, freighting companies etc

...more

through put weigher

Overview: The system finds extensive use in process industries where monitoring the quantity of materials coming out after completion of a process, especially where materials like powder, granules etc. are used, which comes out at a very low rate, say in the order of under 5T per day or lesser. It is extensively used in the tea industry. The system consists of a buffer hopper and a weigh hopper both provided with gates. The weigh hopper is mounted on loadcells. These loadcells are connected to an indicator where the set value can be entered. As soon as the weight in the weigh hopper achieves the set value, the buffer hopper gate closes and the weigh hopper gate opens to discharge the weighed quantity of material on to a down stream process line. The electronic indicator registers the exact quantity of material. As soon as the weigh hopper becomes empty, the gate closes and the buffer hopper gate opens and the process continues

...more

tension load cell

Overview: Tension loadcells are used only to measure tension loads, it is rugged and has a very high precision. It is suitable for very high force applications. Applications: Tower testing, High capacity crane scales, Various off shore and marine applications.

...more

Strain Gauge

Strain Gauge distributed by Preethitech are of foil type and comes in two different impedances which are 120 Ohms and 350 Ohms. These are used in the manufacture of loadcells and various strain measurement applications. We also manufacture nickel gauges for : Span compensation Temperature compensation You can have all the accessories like adhesives, cleaning agents, elements for bonding of strain gauges etc. from us.

...more

Steel Single Point Load Cell

Material : Stainless Steel

Application : Large Platform Scale Steel Weighers

solid flow meter

These metering devices are used to measure the flow rate of very fine particles like fly ash, cement etc. The material flows by gravity through an air slide and flows over a plate which measures the impact which is proportional to the density of the material and the flow rate. The impact on the plate is measured by two high precision loadcells that give a very linear output proportional to the flow rate. The output of the loadcells are fed into the micro controller based flow rate indicator which gives the rate and totalized quantity of material. The solid flow meters can be used in series with a rotary air valve or dozing valve to have a controlled feed of material. These metering devices are extensively used for truck loading and fly ash handling systems. Call us for quality solid flow meters in India.

...more

SINGLE SHEAR CELL

Overview: Similar to the bending beam, the shear beam loadcells can be used in very harsh industrial environments for measurement of compressive and tensile forces. Applications: Tank weighing and vessel weighing, dynamic weighing typically in conveyor applications, platform scales etc.

...more

signal conditioner

Overview: Signal Conditioners is a wall-mounting instrument compatible with strain gauge based transducers. It can support a maximum of 4 transducers when they are connected in parallel. Signal conditioners are used to accept for further processing of output signals. After which they are converted into voltages and currents. Voltage signals are used for processing with in the system and current signals are used for transmitting over long distances and then for further processing. The features of the signal conditioner are: • Output proportional to load• Simple to operate• Reliable• Easy to install• Rugged designed for industrial environmen

...more

SCREW FEEDER

Overview: In the case of conveying of bulk materials which has material characteristics like free flowing by nature, which packs under pressure, which are very light and fluffy i.e., may be windswept and materials with very high temperature, in such cases belt feeders are not suitable ; only Screw Feeder are recommended. The Gravimetric Screw Feeder is custom engineered compact, enclosed and eco-friendly equipment that finds applications in continuous bulk proportioning of solids. This gravimetric feeder operated by a closed loop control system enables feeding at a controlled rate and exercises precise control over rate of flow. The system is capable of accepting external signals from other controllers or from the process computer, depending on the extent of plant instrumentation. These gravimetric feeders are in operation in cement, fertilizers and chemical industries. Each system consists of control panel, local panel, loadcell to measure the instantaneous load, tacho to sense the speed of the screw which is mounted inside closed trough. The screw shaft is driven by a constant speed AC motor coupled through a gear box.

...more

Rope Tension

Overview: Rope Tension is a special loadcell used for measuring the tension on a rope. It is clamped on to the rope and is used to measure the slackness or tension of a rope on a crane. It is widely used in cranes for overload protection and rope slackening prevention. Applications: Crane/Hoist Over load Monitoring Systems ,Rope Tension Monitoring Systems, Tower Testing Applications, Lift Over load Monitoring Systems

...more

Pressure Transducers

Overview: We offer strain guage based pressure transducers with and without integrated amplifier. We are also launching the digital pressure transducer- with a digital output. Our pressure transducers are very rugged and can be used for all media compatible with steel. With a stainless steel enclosure, these tough pressure transducers are available from 5 kg/cm² to 300 kg/cm². Applications: Hydraulic & Pneumatic Plants Steel&Cement Industries Marine & Refineries Chemical Industries Food Processing Industries

...more

Preethitech Accelerometer

Overview: Preethitech Accelerometer utilizes the spring-mass system for generating a force proportional to the amplitude of the input acceleration to the base of the system. Force is applied to the piezoelectric (PE) element made of leadzirconate –titan ate (PZT) material that produces a charge output proportional to the force. The PE material is self-generating and does not require an external power source. Applications: Our Accelerometers are single ended compression (SEC) design, which provides high sensitivity and high resonant frequency. A special type of base construction is used to minimize effects of base strain, which makes the device useful for reliable low signal level measurements. The Piezoelectric Accelerometer construction is entirely of stainless steel. It carries standard 10-32 UNF miniature connector for output connection and is suitable for application in low-level vibration measurements at frequencies down to 0.1 Hz in laboratory and industrial environments.These accelerometers are best suited for vibration analysis in harsh industrial environments

...more

LOSS IN WEIGH FEEDER

Overview: Loss in-Weigh Feeders operate on the principle of controlled loss-in-weight. The proposed system comprises of a Weigh Hopper, Loadcells, Screw Conveyor with motor and associated control electronics. The Weigh Hopper and Screw Conveyor are mounted on 3 Nos. of Loadcells. The Loadcells are connected to a controller through a junction box.The material from the storage hopper is fed to the weigh hopper, which is controlled by a gate. A small screw feeder is mounted below this weigh hopper. The weigh hopper and screw feeder are mounted on high precision Loadcells and the output of the Loadcells are summed in a junction box and fed as an analog input to the controller. The controller calculates the rate, compares with the set rate and feeds the corresponding 4-20mA signal to the VVVF drive so as to control the speed of the motor of the screw, thereby controlling the rate of discharge.

...more

Mild Steel Hopper

PreethiTech provides Hopper / Tank / Silo / Bin Weighing Systems offer simple, rugged, accurate and reliable weighing. It ranges from 5 KGs to any Tonne capacity depending upon single loadcell arrangement or multiple loadcells. Single load cell conversion is best suited for Liquid Weighing and in the case where only level indication is required. For Hopper and Silo Weighing System, generally, three loadcell mounting arrangement is ideal. But, for horizontal tank, four loadcell based systems are recommended and for outdoor application, hermetically sealed loadcells are preferred. The Indication for Hopper / Tank and Silo Weighing System can be Level / Weight, which is available either as Wall Mounting Type or Panel Mounting Type. Today we have digital load cells that can make the whole process of installation and trouble shooting easier.

...more

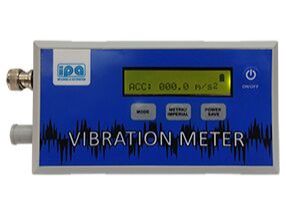

hand held vibration meter

Overview: Hand-held Vibration meter(VM516A0) is a portable and easy to use instrument which is used in conjunction with Integrated Electronics Piezoelectric (IEPE) accelerometers to measure mechanical vibrations in terms of acceleration, velocity and displacement. It is suitable for both laboratory and field conditions.This instrument can be used to monitor vibration levels in production machines on a periodic basis, so that action can be taken before a complete machine failure. It’s operation is simple and quite suitable for use by nonscientific personnel not conversant with electronic instrumentation. In combination with IPA piezoelectric accelerometers the unit provides direct read out of vibration parameters on a LCD screen in both Metric and Imperial units. The device uses a 2200mah rechargeable battery which gives a battery life upto 70hrs continuously following a full charge. It features a dedicated power save button for extended battery life. An output of 2V DC (F.S) is available for recording purpose. Applications: • Industrial Blowers.• Cooling Towers.• Electric Motors.• Diesel Engines.• Small Turbines.• Industrial Gearboxes.• Centrifuges and Decanters.• Centrifugal Pumps.• Test Benches.• Conveyers.

...more

Force Calibrator

Force Calibrator is designed to revalidate a loading system (UTM) or a hydraulic press from time to time. The system consists of a precision load cell / pressure transducer connected to the Force Calibrator, , which works on a single 9V battery with a 7 segment 10mm height, LCD display. To increase battery life a sleep mode has been incorporated. The indicator goes into a sleep mode if there is no change in reading beyond 5 counts within a span of 15 mins, thereby increasing battery life. The sleep mode can be revoked without any change in reading subject to load being held constant. The unit is factory calibrated using standards that has been calibrated in a national standards lab.

...more

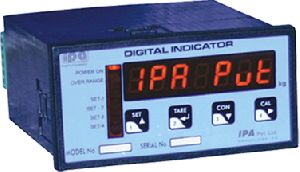

field-programmable indicator

Overview: This is a field-programmable indicator designed to be used with strain gauge based transducers. The salient features are:Simple installation. Accurate operation under varied condition. Unambiguous digital display, distant visibility. Micro-controller based operation. RRS232/Modbus/Profibus communication options. The indicator can be programmed through keypad for range, resolution, filter time constant, decimal point and set points. Tare, calibration and system reset are also performed through keypad. The front panel has got digital display and keypad.Hopper /tank/silo weighing application• Peak load indicator• Bagging machine• Lorry weigh bridge application• Wagon tippler application• Dynamic weighing such as Belt weighers• Loss in weight application• A host of other custom built applications can be built over this little wonder.

...more

Dynamic Load Cell

Double Shear Load Cell

Overview: The shearbeam load cell can be either cylindrical or rectangular. The strain gauges are placed at the bottom of the blind holes. The strain gauges are mounted on the beam at 45 degrees to the longitudinal axis. When the load is applied to the beam, gauges along 45 degrees become longer (tension), along 135 degree become shorter (compression), thereby unbalancing the bridge. The shear beam load cell is insensitive to lateral forces, and point of application of torque is not critical. Shear Beam Loadcells with IP-68 pro

...moreBe first to Rate

Rate ThisOpening Hours