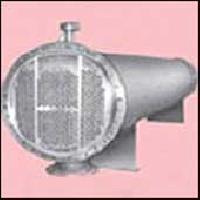

KETTLE TYPE REBOILER

Get Price Quote

Stripping hydrogen sulfide and ammonia from refinery sour water prior to subsequent reuse or wastewater treatment calls for highly reliable, corrosion-resistant, low-fouling equipment. BCS heat exchangers do the job, minimizing fouling and corrosion problems in refinery sour water strippers in refineries world-wide while maximizing energy efficiency and uptime. Energy is recovered when sour water is preheated before the stripper by means of stripped water. The more energy recovered in this service, the less energy needs to be provided to the stripper reboiler in terms of steam. The stripper reboiler is generally designed as a kettle-type reboiler. These typically require a large temperature difference between the boiling media and the steam. This means that a higher pressure steam is required to run the reboiler. When our exchangers are used as rising film thermosiphon reboilers for the sour water stripper column, a temperature difference of less than 10°C is possible to initiate boiling and create natural circulation through the reboiler. This often means that it is possible to use more readily available low-pressure steam instead of medium-pressure steam. Applications : Chemical Plants Refineries Reboiler Distillation Towers Kettle Reboiler Features: We design Kettle Reboiler as per ASME SEC VIII Div-1 standards and TEMA standards. We analyze and calculated the Mechanical and Thermal Design. Phase Exchanger constructed by us is in accordance to the ASME Sec-II Part A & B We have qualified welders for all types of welding joints for structural work. We have our own facility for POST WELD HEAT TREATMENT, NDE. We also provide Hydro Test, Pneumatic Test facilities.