Air Cooled Condenser

Get Price Quote

We are United Heat Exchanger providing solution for Air condensation system for all types of Thermal Power plants.In systems involving heat transfer, a condenser ( Air Cooled Condenser )is a device or unit used to condense a substance from its gaseous to its liquid state, typically by cooling it. In so doing, the latent heat is given up by the substance, and will transfer to the condenser coolant. Condensers are typically heat exchangers which have various designs and come in many sizes ranging from rather small (hand-held) to very large industrial-scale units used in plant processes. For example, a refrigerator uses a condenser to get rid of heat extracted from the interior of the unit to the outside air. Condensers are used in air conditioning, industrial chemical processes such as distillation, steam power plants and other heat-exchange systems. Use of cooling water or surrounding air as the coolant is common in many condensers. Specifications : A condenser unit used in central air conditioning systems typically has a heat exchanger section to cool down and condense incoming refrigerant vapor into liquid, a compressor to raise the pressure of the refrigerant and move it along, A fan for blowing outside air through the heat exchanger section to cool the refrigerant inside. Applications : A typical configuration of such a condenser unit is as follows: The heat exchanger section wraps around the sides of the unit with the compressor inside. In this heat exchanger section, the refrigerant goes through multiple tube passes, which are surrounded by heat transfer fins through which cooling air can move from outside to inside the unit. Advantages : There is a motorized fan inside the condenser unit near the top, which is covered by some grating to keep any objects from accidentally falling inside on the fan. The fan is used to blow the outside cooling air in through the heat exchange section at the sides and out the top through the grating. These condenser units are located on the outside of the building they are trying to cool, with tubing between the unit and building, one for vapor refrigerant entering and another for liquid refrigerant leaving the unit. Of course, an electric power supply is needed for the compressor and fan inside the unit.

Finned Evaporator

Get Price Quote

Finned Tube can also be suitable for liquid cooling applications. Copper is specified in supply and return manifolds and in tube coils. Finned Tube heat exchangers are most commonly used for forced air heating and cooling systems, such as with indoor and outdoor wood furnaces, boilers, and stoves.

Best Deals from Refrigeration Spare Parts

Air Cooled Condenser

Get Price Quote

Air Cooled Condenser condensate exhaust steam from the turbine and it return the condensate to the boiler. That is in power plants steam is used to rotate the turbine. After the application, the steam will be a waste one. So as an economical part of operation, the steam is re condensate to water and then re-used for boiler feed water. The Air Cooled condenser is made of modules arranged in parallel rows as like Air Cooled Heat Exchanger. The module contains number of Finned Tube bundle. The axial flow forced draft fan is fixed in the module and forces the atmospheric cooling air across the Condensate area of the fin tubes.

water cooled condenser

50,000 - 120,000 Per Piece

1 Piece (MOQ)

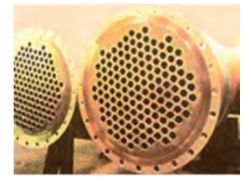

Premier offers cleanable Shell & Tube Integrally Finned Water Cooled Condensers from 3TR to 200TR capacity. These Condensers are built in a wide variety of sizes from 6 inch to 24 inch in diameter. Length vary from 3 feet to 20 feet over the tube heads.The Condensers are designed for a pressure of 20 Kg per sq.cm gauge on shellside and 7 Kg per sq.cm gauge on water side. They are tested upto 28 Kg per sq.cm gauge on the shell side & 10 Kg. per sq.cm gauge on water side. The Condensers are fabricated as per TEMA / ASME unfired pressure vessels codes & ASHRAE standards requirements. Condensers for sea water marine application or with steels shells are also offered & designed as per customer specific requirements.

Mild Steel Condenser

Get Price Quote

JC Air Cooled Condenser

Get Price Quote

JC Equipments are certified ISO and ASME (The American Society of Mechanical Engineers) company with 23 years experience in Heat Exchanger Industry. We are manufacturing of heat exchangers since 1990. JC Equipments are speacially designed and developing of Air Cooled Condenser for all types of Thermal Power plants and indusries, Oil Plants and Gas Plants. JC has the good quality manufacturers and installing capability to supply the most excellent air cooled condenser for every applications. Air Cooled Condensers Types are : Natural Convection and Forced Convection. Components of Air Cooled Condenser System Ejectors 3Bellows Instrumentation Pipe Lines Strainers Valves Civil construction Cleaning system Fans ,Motor & Gear box Parts of Air Cooled Condenser System Expansion bellows Hogger Ejection system Condensate extraction pumps Drain pot Pumps Inter condenser After condenser Condensate storage tank Gland steam condenser Drain Pot Difference Between Air Cooled Condenser and Water Cooled Condenser Air Cooler An air condenser is generally a lesser amount of valuable for condensing gases, for the reason that of the slower cooling time. However, if the gases are extremely hot, the icy water be able to cause the condenser to crack. Air cooled condenser remove heat by blowing air over the condenser coil. The Air cooled condensers, as well referred to the same as "fin and tube" condensers, are in all probability the most able to be seen component in an air conditioning system, be it a room or packaged air conditioner or a packaged chiller. If the condenser has water curving interested in the top part first, it will just run in a straight line through and not cool the vapour. by means of filling it from the base, the water is forced into the condenser and fills it totally. Water cooled condenser remove heat by pouring water over the condenser coil. Spares of Air Cooled Condenser The below spare lines also have required valves for operation. By this way the continuous operation of Condensation system is ensured by JC Equipments Pvt Ltd. Inter and after condenser Ejectors Condensate extraction pump Drain pumps Air Cooled Condenser Working Principle Air Cooled Condensers Types Natural Convection Forced Convection. Natural Convection occurs when a heater with a reduction of dense fluid is pressed left by a cooler denser fluid. Forced Convection occurs when an outer force pushes a fluid, such the same as water of air, to create it move about and transfer heat. Air Cooled Condenser Design The nearly all accepted style of Air Cooled Condenser is the modularized ('A' frame structured design), used on industries and power plants of all sizes. Our design teams are updated new technology of the Air Cooled Condenser design for all types of industries. The Air Cooled Condenser design group will discuss about Technical aspects of Air Cooled Condenser for Power Plants and also more industries. The 'A' frame structured designs are mostly used in the power plants. Coil Design : Advanced Smart Circuitry Coil Technology Our Air Cooled Condenser Design Process Contains for Thermal Design. Air Cooled Steam Condenser Problem A successful air cooled steam condenser be required to continuously and totally gather and ejection all of the non condensables in the system. The non condensable are left behind inside the tubes and headers when the steam condensers Applications of Air Cooled Condenser All Thermal power plants Gas based Plants Coal based plants Oil Plants Biomass power plants Refrigerant hot gas piping Nuclear power plants

Air Cooled Condenser (acc)

Get Price Quote

The gireesh is a well known manufacturer of a high quality range of Air Cooling Condenser which are high on demand in the market and they can be got customized by the clients as per their requirements. These products are made using advanced technology and they offer a high performance to the customers. They are easy to install and consume a very low amount of electricity. These products are very durable and offer a long lasting service life to the customers Gireesh Process cooling with air as cooling medium is used successfully in many industry branches. With steadily increasing costs for cooling water it also becomes more and more important in the power industry. At locations where cooling water is not available it is often the only possibility for the cooling of process streams.

Air Cooled Condenser

Get Price Quote

The nearly all accepted style of Air Cooled Condenser is the modularized ('A' frame structured design), used on industries and power plants of all sizes. Our design teams are updated new technology of the Air Cooled Condenser design for all types of industries. The Air Cooled Condenser design group will discuss about Technical aspects of Air Cooled Condenser for Power Plants and also more industries. The 'A' frame structured designs are mostly used in the power plants. Coil Design : Advanced Smart Circuitry Coil Technology Our Air Cooled Condenser Design Process Contains for Thermal Design.

Air Cooled Condenser

Get Price Quote

Dry Cooling towers are produced in forced draught and induced draught designs, and in single and multi-fan arrangements, depending customer specifications and requirements, We are the professional dry cooling tower and air cooled condenser manufacturers, tubes in copper and fins are aluminium MOC we use 58’ or 38’ OD copper tubes as per customer specification, all tubes are well expanded tested for pressure and leak.

Air Cooled Condenser

Get Price Quote

Components of Air Cooled Condenser System Ejectors 3Bellows Instrumentation Pipe Lines Strainers Valves Civil construction Cleaning system Fans ,Motor & Gear box Parts of Air Cooled Condenser System Expansion bellows Hogger Ejection system Condensate extraction pumps Drain pot Pumps Inter condenser After condenser Condensate storage tank Gland steam condenser Drain Pot Difference Between Air Cooled Condenser and Water Cooled Condenser Air Cooler An air condenser is generally a lesser amount of valuable for condensing gases, for the reason that of the slower cooling time. However, if the gases are extremely hot, the icy water be able to cause the condenser to crack. Air cooled condenser remove heat by blowing air over the condenser coil. The Air cooled condensers, as well referred to the same as "fin and tube" condensers, are in all probability the most able to be seen component in an air conditioning system, be it a room or packaged air conditioner or a packaged chiller. If the condenser has water curving interested in the top part first, it will just run in a straight line through and not cool the vapour. by means of filling it from the base, the water is forced into the condenser and fills it totally. Water cooled condenser remove heat by pouring water over the condenser coil. Spares of Air Cooled Condenser The below spare lines also have required valves for operation. By this way the continuous operation of Condensation system is ensured by JC Equipments Pvt Ltd. Inter and after condenser Ejectors Condensate extraction pump Drain pumps Air Cooled Condenser Working Principle Air Cooled Condensers Types Natural Convection Forced Convection. Natural Convection occurs when a heater with a reduction of dense fluid is pressed left by a cooler denser fluid. Forced Convection occurs when an outer force pushes a fluid, such the same as water of air, to create it move about and transfer heat. Air Cooled Condenser Design The nearly all accepted style of Air Cooled Condenser is the modularized ('A' frame structured design), used on industries and power plants of all sizes. Our design teams are updated new technology of the Air Cooled Condenser design for all types of industries. The Air Cooled Condenser design group will discuss about Technical aspects of Air Cooled Condenser for Power Plants and also more industries. The 'A' frame structured designs are mostly used in the power plants. Coil Design : Advanced Smart Circuitry Coil Technology Our Air Cooled Condenser Design Process Contains for Thermal Design. Air Cooled Steam Condenser Problem A successful air cooled steam condenser be required to continuously and totally gather and ejection all of the non condensables in the system. The non condensable are left behind inside the tubes and headers when the steam condensers Applications of Air Cooled Condenser All Thermal power plants Gas based Plants Coal based plants Oil Plants Biomass power plants Refrigerant hot gas piping Nuclear power plants

Air Cooled Condensers

Get Price Quote

Air Cooled Condensers, Air Cooled Heat Exchanger, Cooling Towers

Air Cooled Condenser

Get Price Quote

The manufacturing of air cooled condenser is made of modules arranged in parallel rows as like air cooled heat exchanger. The air cooled condenser condensate exhaust steam from the turbine and it return the condensate to the boiler. That is in power plants steam is used to rotate the turbine. After the application, the steam will be a waste one. So as an economical part of operation, the steam is re condensate to water and then re-used for boiler feed water. If your air cooled condensers (acc) are not operating at their optimum they are losing money. by using tube tech international’s innovative air cooled condenser cleaning service lower production rates, higher mechanical costs, higher maintenance costs plus lost time in both machinery and manpower will be problems of the past. Air cooled condenser tube cleaning with specialist industrial cleaning will make a huge difference to your operation. You will increase performance, improve safety, reduce your carbon emissions and reduce overall downtime the major benefits of air cooled condenser are: elimination of additional water usage from the condensing power cycle flexibility in power plant site selection decreased time required for plant permitting the fin tube is the core technology of the air cooled condenser. single-row condensers (src) - an elongated, flat tube with brazed aluminum fins. multi-row galvanized (mrc) - an oval tube with hot-dip galvanized steel fins.

Ac Condenser

Get Price Quote

Ac Condenser, Condensers

Fruits Condenser

Get Price Quote

Fruits Condenser, Walking Beam Furnace, roller kiln, Car Bottom Furnace

Condensers

Get Price Quote

Condensers, Laboratory Funnels, Volumetric Flask, serving dishes