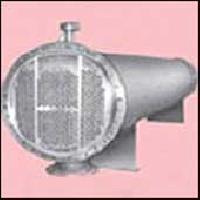

Stainless Steel Heat Exchanger

Get Price Quote

JC Equipments are leading suppliers and manufacturers of Stainless Steel Heat Exchanger and all types of heat exchanger in india and also welded stainless steel tubes and pipes for a wide range of applications. We are into manufacturing of heat exchangers since 1990. ASME certified (The American Society of Mechanical Engineers) manufacturers in india. We are huge and specialized exporter for stainless steel heat exchanger products and get pleasure from good standing for the reason that of our high quality and competitive price. JC SS heat exchangers are manufactured and developed with TIG welding and mirror or dull buffing finish.

JC Stainless Steel Shell and Tube Heat Exchanger

Get Price Quote

JC Equipment also manufacturer Stainless Steel Shell and Tube Heat Exchanger in India as per your requirements. As name implied the Stainless steel heat exchanger that is composed of stainless steel. Send your details application and requirement to get our best design for your steel type heat exchanger. Shell and Tube Heat Exchanger Design: JC Equipments Coimbatore India design Shell and Tube Heat Exchangers by two major types. Thermal Design for Shell and Tube Heat Exchanger Mechanical Design for Shell and Tube Heat Exchanger Shell and Tube Heat Exchanger Application: During the manufacturing process industries are in need of heat exchangers to transfer or the heat by using many types. The shell and tube heat exchanger is specially design and suites for higher-pressure applications. Shell and Tube Heat Exchanger for Power Plants – Condensers, Pre Heaters, Waste water treatment Shell and Tube Heat Exchanger for Oil Refineries – Inter cooling Purpose, Re Processing Purpose, Shell and Tube Heat Exchanger for Manufacturing Industries – Oil coolers for Quenching Oil Oil coolers for Lubrication Oil Offshore Industry Water Makers Condensers, Power Plants – Chillers and Water Coolers Food and Dairy Industries, Refrigeration systems, Pulp and Paper Industries, Wine-brewery industry, plastic and Fertilizers Industries Shell and Tube Heat Exchanger Standards: We manufacture Shell and Tube Heat Exchanger equipments asper the TEMA [Tubular Exchanger Manufacturers Association] standards, ASTM section(VIII)(unfired pressure vessuls), is-4503, is-6088 standards. And asper bs, din standard's and is 2825 is 6088 codes. Shell and Tube Heat Exchanger Quality : JC Equipments having its quality control department [QC Control] testing of all its Shell and Tube Heat Exchanger. Problem and Trouble shooting Shell and Tube Heat Exchanger: JC Equipments are well explained the Trouble shooting of Shell and Tube Heat Exchanger. Nano Technology on Shell and Tube Heat Exchanger : We are closly watching this technology and will be adapted for our existing clients as upgradation of Shell and Tube Heat Exchanger.

Best Deals from Stainless Steel Heat Exchanger

Stainless Steel Heat Exchanger

50,000 - 1,000,000 Per Piece

1 Piece (MOQ)

Stainless Steel Heat Exchanger

Get Price Quote

Stainless steel also known as inox steel, is defined as a steel alloys with a minimum of 10.5%to 11% chromium content by mass. Stainless steel does not flake, rust or stain with water as regular steel does, but in spite of the name it is not fully stain-proof. Stainless steel is also called corrosion-resistant steel or CRES when the alloy type and not exhaustive, particularly in the aviation industry. There are different grades & surface finishes of stainless steel to go with the environment the alloy must endure. Stainless steel is used where both the properties of steel & fighting to corrosion are m&atory. Stainless steel differs from carbon steel by the amount of chromium present.

Stainless Steel Heat Exchanger

Get Price Quote

We are an eminent manufacturer, supplier and exporter of high quality heat exchangers that are used for exchanging and transferring heat in various industries. These heat exchangers have been manufactured using stainless steel of ss 304, ss 304 l, ss 316 and ss 316 l. Our heat exchangers are highly demanded in the market owing to its durability and effective performance. range: • steel heat exchanger • fixed shell heat exchangers • stainless steel heat exchanger • tube heat exchangers • floating heat exchanger • fully double expanded heat exchanger • double tube sheet type heat exchanger

Stainless Steel Heat Exchanger

Get Price Quote

Stainless steel of threaded joints may be lubricated to prevent galling. Because of the durability of the material, many of these buildings retain their original appearance. Stainless steel reduce the tendency to gall through selective alloying with manganese and nitrogen. Stainless steel of this is the upper portion of the Chrysler Building pictured. Some diners and fast-food restaurants use large ornamental panels.

Stainless Steel Heat Exchangers

Get Price Quote

We are the leading manufacturers of welded stainless steel tubes and pipes for a wide range of applications. Stainless welded pipes and heat exchanger tubes for the industrial usages. Stainless steel heat exchangers are particularly useful in bad water environments caused by pollution or from the chemicals used to counter it. They can also be used to overcome the corrosive nature of some synthetic oils and refrigerants. Stainless steel heat exchangers are particularly useful in bad water environments caused by pollution or from the chemicals used to counter it. Stainless Steel Heat Exchanger Design Stainless steel heat exchanger are highly corrosive in nature and other special applications. Stainless steel heat exchanger are designed and manufactured, employing the industry standards and are also custom designed according to the client specifications and requirements. Stainless steel heat exchanger is mostly used to reduce heat from high temperature liquids and is appreciated for its durability and long service life. Features of Stainless Steel Heat Exchangers Material used: Stainless steel High efficiency and Low consumption It is made of imported stainless steel pipe. Easy cleaning and maintenance Stainless Steel Heat Exchangers Advantages are, Easy to install, Good quality, Low Cost, Easy cleaning and maintenance, Affordable, Efficient designs that lower operating costs, Highly durable Stainless Steel Heat Exchanger Applications 1. Cooling corrosive fluids in chemical,2. pharmaceutical or refining processes.3. Electrical industry4. Chemical industry5. Power Plants6. Heating and air conditioning