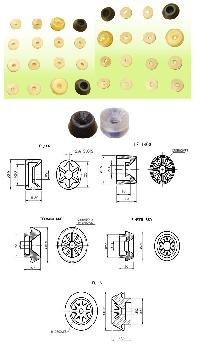

comber spares

Get Price Quote

gyrating has a state of art manufacturing facility to produce quality critical spares & accessories for Rieter and LMW Combers Comber Spares are manufactured by sourcing right raw materials as in the case of OEM Comber spares and other components are manufactured with the help of SPM's to maintain the critical dimensions of the spares & components are equalent to OEM manufacturer

Pin Beaters

Get Price Quote

Best Deals from Textile Machine

Cone to hank Yarn Reeling machine

1,050,000 - 1,150,000 Per piece

1 piece (MOQ)

Textile Blow Room Machine

665,000 Per Unit

1 Unit (MOQ)

Fabric Meter Folding Machine

Get Price Quote

Woven Fabric Meter Folding Machine - Consisting of Power De- Rolling Cradle Arrangement Folding Operation through Servo Motor Pneumatic Fabric Catcher Arrangement Power drive Folder Table (up & down) Movement through Gear Motor-PLC Controlled Panel Board

textile machine components

Get Price Quote

Cotton Waste Recycling Machines

420,000 Per Carat

reeling machine

Get Price Quote

Clutch pulley, Loose pulley, Fan pulley, Swift bearing Doffing side, Driving side swift bearing, Heavy pipe, Heavy arms, Wooden & Steel Reapers, Index wheel, Bevel wheels, Worm wheels, Rack RH & LH, 6 Feet brush, Traverse motion assembly, ELECTRONIC STOPMOTION PHOTO CELL ASSEMBLY ETC.

Drawframe Spares

350 Per Piece

Cotton Tearing Machine

600,000 Per Unit

fabric relaxing machine

Get Price Quote

false twisters

Get Price Quote

We offer false twisters. Over the years of experience in the industry, we have been able to provide the customers with a commendable range of False Twisters.

Yarn Bundling Machine

Get Price Quote

Flocked Clearer Roller Cleaning Machine

Get Price Quote

Ring Doubler Machine

Get Price Quote

Garment Fusing Machine

20,000 - 50,000 Per

45000.00 Piece (MOQ)

Hydraulic Cotton Baling Press Machine

200,000 Per Piece

1 Piece (MOQ)

Weaving machine

Get Price Quote

Weaving machine

Cotton Contamination clearer Machine

1,400,000 - 2,500,000 Per Each

GENN is proud to introduce the GINNING SORTER, a real time system for the detection and removal of contaminants from raw cotton in the blow room line. All unwanted material that differs from the cotton throughput is detected by Ultra fast CCD cameras and removed by means of high speed air guns. GENN COTTON SORTEX is the latest addition to GENN's textile electronic products with our state of art modular technology; customer is benefited with integrated, accurate and efficient product. Features 5400 Pixels Advanced Linear CCD Double side Viewing Manual IRIS/Focus Lens Minimum Detecting size 0.088mm

Electronic Ribbon Breaker

22,000 Per Piece

1 piece (MOQ)