Shell & Tube Heat Exchanger

Get Price Quote

Shell & Tube Heat Exchanger

Get Price Quote

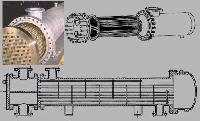

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact. We are a dependable Manufacturer, Supplier and Exporter of Shell & Tube Heat Exchanger. Also, these Shell & Tube Heat Exchangers are designed as per the leading-edge technology. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Shell & Tube Heat Exchanger, which we offer, can be operated within a temperature range of -40oC to 150oC on either side. However, differential temperature should not exceed 120oC at any point. All the Shell and Heat exchangers can be use pre-dominantly under full vacuum, provided differential pressure does not exceed 3 bar g. Details Type: Fixed Tube Sheet, Removable tube Bundle, U-Tube, Coil in Tank, double PipeCapacity Range : As per Customer requirementShell Diameter : 4� to 125�Tube Length : 3� to 40�Tubes : Plain, Integrally Finned or U-TubeNo of Passes: Single, Double & Four passesM.O.C. Tubes : Carbon Steel, Stainless Steel, Copper, Adm. Brass, Aluminium, Titanium, Tantalum, Hastolloy, Aluminium Bronze, Monel, Duplex, CupronickleShell : Carbon Steel, Stainless Steel, Copper, Monel. Brass, AluminiumChannels : Carbon Steel, Stainless Steel, Gun Metal, Cast Iron, Brass, Cast Aluminium, Alloy Technical Information : All the Shell & Tube Heat Exchanger are constructed with 12 mm OD, 1.5 mm thick glass tubes. These tubes are arranged in triangular pitch of 21 mm. Baffles are provided with 30% cut at a distance of approximately equal to inner diameter of shell. Generally, PTFE baffles are used in Glass shells and PP baffles in Metal Shells. Our Applications DG set for all capacitySpace heatingRefrigerationAir conditioning Power plantsChemical plantsPetrochemical plantsPetroleum refineriesNatural gas processingSewage treatment

Best Deals from Tube & Shell Heat Exchangers

Shell and Tube Heat Exchanger

5,000 - 500,000 Per Set

1 Set(s) (MOQ)

Shell and Tube Heat Exchanger

Get Price Quote

1 Piece (MOQ)

SHELL AND TUBE HEAT EXCHANGERJanani Enterprises designing the shell and tube heat exchanger is quite result oriented for process industries and for Oil Cooling. The tubes used internally are deliberately of various shapes and design to obtain different outcomes. While a few of the tubes may be plain, others may come finned longitudinally or horizontally. Additionally, the tubes can also be of various materials and thermal conductivity. For instance, Janani Enterprises Equipments can be designed from carbon steel, stainless steel, cupronickel, copper or brass.Testing Of Heat ExchangerOwing to the complex nature of the shell and tube heat exchangers, regular inspection of the equipment is necessary. This can help to assess the thickness of the tube walls that are prone to fitting, erosion and corrosion over time. The status of the whole bundle of tubes may be charted and assessed through a thorough inspection with the help of a device known as Internal Rotary Inspection System that functions via ultra sonic testing and also has a non-destructive nature.Application : Chemical, Petrochemical, Fertiliser. Thermal Power plants, Refrigeration Plants, Marine Engines, Turbines, Hydraulic Systems, Sugar Machinery

Shell and Tube Heat Exchanger

Get Price Quote

Shell Tube Heat Exchanger

Get Price Quote

Shell and Tube Heat Exchanger which typically have U-tubes. One fluid runs through the tubes, and another fluid flows over the tubes to transfer heat between the two fluids. They are used to boil water recycled from a surface condenser into steam to drive a turbine to produce power. Most shell-and-tube heat exchangers are either pass designs on the tube side. The Shell and Tube Heat Exchanger can be either liquids or gases on either the shell or the tube side.

Shell & Tube Heat Exchanger

Get Price Quote

We offer all types of shell and tube heat exchanger for all industrial applications. where ever the pressure and temperature is available its required our heat exchanger. In heat exchanger industry the most important type of usage in oil industries and chemical process. This shell and tube heat exchanger having two parts. One is Shell side and another one is Tube side. Features: »High Pressure Shell and tube warm exchangers comprise of a progression of tubes. The second liquid keeps running over the tubes that are being warmed or cooled with the goal that it can either give the warmth or ingest the warmth required.One arrangement of these tubes contains the liquid that must be either warmed or cooled. High Pressure Shell Tube Heat Exchanger is generally utilized in assortment of use as a cooling arrangement. Applications: »Air conditioning Chemical Industries Power plants Heat Processing Industries Thermal Power Plants Petroleum refineries Natural Gas Plant Advantages: »Shell Tube Heat Exchanger is frequently simple to benefit, especially with models.

Shell Tube Heat Exchanger

Get Price Quote

We JC Equipments Pvt Ltd take Pleasure to Introduce Ourselves as one of the leading Designers, Manufacturers & Exporting of all kind of Cooling Towers,Heat Exchangers Pressure Vessels Columns, Storage Tanks, Air Cooled Condensers, etc... in India. JC Equipments Pvt Ltd started in the Year of 1989. We have wide knowledge in this field and we have Regular customers throughout the world. We are AUTHORIZED MANUFACTURERS OF ASME and we have “U, S & R” Stamp Certification also. We are CORPORATE MEMBER OF CTI, USA. We are a WORLD CLASS MANUFACTURERS and we never compromise in Quality. We assure Our Product will be best quality and competitive price. Herewith we have enclosed the product profile for your kind reference. Kindly refer the attachment. Looking forward your valuable enquiry for us to quote our best and competitive offers, with assuring you of our best quality and prompt service at all times.

Shell Tube Heat Exchanger

Get Price Quote

Vertical Shell and tube heat exchangers consist of a series of tubes. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required.One set of these tubes contains the fluid that must be either heated or cooled. Vertical Shell Tube Heat Exchanger is widely used in variety of application as a cooling solution.

Shell and Tube Heat Exchanger

Get Price Quote

Gireesh shell and tube heat exchanger is the most common type of heat exchanger designs. As its name implies, this type of heat exchanger consists of a shell with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed by several types of tubes: plain, longitudinally finned, etc. process liquid or gas cooling process or refrigerant vapour or steam condensing process liquid, steam or refrigerant evaporation process heat removal and preheating of feed water thermal energy conservation efforts, heat recovery compressor, turbine and engine cooling, oil and jacket water hydraulic and lube oil cooling

Shell & Tube Heat Exchanger

Get Price Quote

We are offering shell and tube heat exchanger offered features presence of series of finned tubes that are used for running the fluids for meeting the demands of heating and cooling purposes. These shell and tube heat exchangers are perfectly designed to find suitability for heat transfer of lubricating oil, fluids, power pack oil as well as other process coolants and can be made available in wide range of shell diameters so as to find suitability for different load ranges. Features: high performance range of shell and tube heat exchangers suitable for meeting the heat transfer needs of lubricating oil, fluids and other process coolants available in different shell diameters suitable for a wide load range requiring low maintenance

Shell Tube Heat Exchanger

Get Price Quote

We at JC Equipments Pvt Ltd in coimbatore offer world class heat exchanger particularly shell type. We offer all types of shell and tube heat exchanger for all industrial applications. where ever the pressure and temperature is available its required our heat exchanger. In heat exchanger industry the most important type of usage in oil industries and chemical process. This shell and tube heat exchanger having two parts. One is Shell side and another one is Tube side. We manufacturer of Fixed Tube Sheet heat exchanger in India as per your requirement and as per the market standards. This JC FIxed Tube Sheet heat exchanger is useful for hight pressure and high temperature based applications. Also for chemical industries and all refinery units are using our Fixed Tube shee heat exchanger. This type of heat exchanger is employed where even slightest intermixing of fluids can not be tolerated. The inside tube sheets are fixed as its name implied.

Shell & Tube Heat Exchanger

Get Price Quote

We offer an exclusive series of Shell & Tube Heat Exchangers that are efficient to handle high pressure and temperature applications. These types of Exchangers find uses in various industrial applications. High capacity and tensile strength is the effective features of our Shell Tube Heat Exchanger. These Heat Exchangers are available in various grades and designs. Moreover, we can offer customized designs of Industrial tube Heat Exchanger. Consequently, we are well-reckoned in the market as one of the most prominent Shell Tube Heat Exchanger Manufacturers in the country. We offer these Heat Exchanger at most discounted prices. Accordingly, we are recognized as one of the most prominent Industrial tube Heat Exchanger Suppliers, based in India.

Shell Tube Heat Exchanger

Get Price Quote

Shell and Tube heat exchangers are suitable for heat transfer fluids,lubricating oil,power pack oil and other process coolants.Models available in wide range(4" to 10") shell diameter suitable for load 1500 KcalHr to 75000 Kcalhr.(2 Hp to 100Hp).

Shell & Tube Heat Exchanger

Get Price Quote

A heat exchanger is a device used to transfer heat between one or more fluids . It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. The simple design of a shell and tube heat exchanger makes it an ideal cooling solution for a wide variety of applications. One of the most common applications is the cooling of hydraulic fluid and oil in engines, transmissions and hydraulic power packs.

Shell and Tube Heat Exchanger

Get Price Quote

Our Shell and Tube Heat Exchangers are furnished with 19 mm copper tubes, carbon steel components, and a durable cast iron head. Our range of Shell and Tube Heat Exchangers provide protection in any event of a leak.

Shell and Tube Heat Exchanger

Get Price Quote

Shell and Tube Heat Exchanger is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. Shell Tubes Heat Exchanger are classified into fixed and Floating type Heat Exchangers . Fixed type Heat Exchangers are used where there are absolutely no chances for inter mixing of two fluids. Shell and tube heat exchangers consist of a series of tubes. One set of these tubes contains the fluid that must be either heated or cooled. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required. In this type, the tube sheets are completely welded to the shell and acted as shell flanges. The Floating type Heat Exchangers has the advantages of removability of tube bundle and access for cleaning both inner and outer side of tubes and shell. Specifications Shell Tube Heat Exchanger stream a process fluid and other cooling water or air. This is an efficient way to conserve energy. Two-phase heat exchangers can be used to heat a liquid to boil it into a gas Applications : Shell Tube Heat Exchanger is widely used in variety of application as a cooling solution. The most common amoung them is for cooling of Hydraulic Fluid and oil in engines, transmissions and hydraulic power packs. With the right coimbination of materials they can also be used to cool or heat other mediums, such as swimming pool water or charge air. One of the big advantages of using a shell and tube heat exchanger is that they are often easy to service, particularly with models where a floating tube bundle (where the tube plates are not welded to the outer shell) is available. Can also be used on fixed tube sheet heat exchangers space heating refrigeration air conditioning power plants chemical plants petrochemical plants petroleum refineries natural gas processing sewage treatment Advantages : Shell Tube Heat Exchanger is often easy to service, particularly with models.

Shell and Tube Heat Exchanger

15,000 Per unit

1 unit (MOQ)

Shell & Tube Heat Exchanger

Get Price Quote

Shell & Tube Heat Exchangers are widely used for liquid to liquid and liquid to gas applications such as oil cooling, condensing, jacket water or gas cooling. Baffles Cooling System can design, fabricate and supply complete Shell & Tube Heat Exchangers in any size or configuration. Our Shell & tube heat exchanger range includes hydraulic oil coolers, marine oil coolers, charge air coolers and swimming pool heat exchangers, all of which feature a fully floating tube bundle designed to prevent fatigue from thermal expansion and improve serviceability. Our shell and tube heat exchangers are designed to be as flexible as possible. By changing the materials of the headers and tubes, the heat exchangers can be used in freshwater and marine environments. We can also adjust the number of fluid passes on both circuits ensuring that the heat exchanger can perform at its most optimal level before increasing the size. This can improve efficiency and reduce costs for our customers. For more specialist requirements however we can design shell and tube heat exchangers with unique characteristics making them a perfect fit for your equipment Shell & Tube Heat Exchanger features: BCS manufacturers Shell and Tube Heat Exchanger that are designed to meet the standards of ASME SEC VIII Div-1 and TEMA standards. We deal in R, C, B application areas We analyze and calculated the Mechanical and Thermal Design. Our Heat Exchangers are constructed to meet the standards of ASME Sec-II Part A & B We have qualified welders for all the welding needs. We have our own facilities for POST WELD HEAT TREATMENT, RADIOGRAPHIC. We are capable of making heat exchanger in all the following materials like CS, SS 304, 316, 304L, 316L, Titanium, Copper, Aluminium, IS 2062, Cupro Nickel, Brass etc. Applications : Space Heating Refrigeration Plant Air Conditioning Plants Power Plants Chemical Plant Petrol Chemical Plant Petroleum refineries Natural Gas Processing Sewage Treatment

Shell and Tube Heat Exchanger

Get Price Quote

C Equipments Pvt Ltd Offer the below types of shell and tube heat exchangers: JC Fixed Tube Sheet Heat Exchanger JC Removable Tube Bundle Heat Exchanger JC Vertical Shell and Tube Heat Exchanger JC Stainless Steel Shell and Tube Heat Exchanger JC U Tube Bundle Type Heat Exchanger JC Fixed Tube Sheet Heat Exchanger India We manufacturer of Fixed Tube Sheet heat exchanger in India as per your requirement and as per the market standards. This JC FIxed Tube Sheet heat exchanger is useful for hight pressure and high temperature based applications. Also for chemical industries and all refinery units are using our Fixed Tube shee heat exchanger. This type of heat exchanger is employed where even slightest intermixing of fluids can not be tolerated. The inside tube sheets are fixed as its name implied. JC Removable Type Tube Bundle Heat Exchanger India JC equipments manufacturer Removable type tube bundle heat exchanger in India for the past 23 Years. Experienced designing team and manufacturing team is added strength for our company. Send your requirement and specification to get our best design for your removable type heat exchanger. Its is easy for maintainence ie., cleaning of removable type is quite easy. We use rubber rings to seal the shell side and tube side. JC Vertical Shell and Tube Heat Exchanger We are the leading manufacturers of Vertical Shell and Tube Heat Exchanger in India.A Vertical Shell and Tube Heat Exchanger is the most common type of heat exchanger in all Industries. Mostly used in higher-pressure and Higher Temperature applications. JC Stainless Steel Shell and Tube Heat Exchanger JC Equipment also manufacturer Stainless Steel Shell and Tube Heat Exchanger in India as per your requirements.As name implied the Stainless steel heat exchanger that is composed of stainless steel. Send your details application and requirement to get our best design for your steel type heat exchanger. Shell and Tube Heat Exchanger Design: JC Equipments Coimbatore India design Shell and Tube Heat Exchangers by two major types. Thermal Design for Shell and Tube Heat Exchanger Mechanical Design for Shell and Tube Heat Exchanger Shell and Tube Heat Exchanger Application: During the manufacturing process industries are in need of heat exchangers to transfer or the heat by using many types. The shell and tube heat exchanger is specially design and suites for higher-pressure applications. Shell and Tube Heat Exchanger for Power Plants – Condensers, Pre Heaters, Waste water treatment Shell and Tube Heat Exchanger for Oil Refineries – Inter cooling Purpose, Re Processing Purpose, Shell and Tube Heat Exchanger for Manufacturing Industries – Oil coolers for Quenching Oil Oil coolers for Lubrication Oil Offshore Industry Water Makers Condensers, Power Plants – Chillers and Water Coolers Food and Dairy Industries, Refrigeration systems, Pulp and Paper Industries, Wine-brewery industry, plastic and Fertilizers Industries Shell and Tube Heat Exchanger Standards: We manufacture Shell and Tube Heat Exchanger equipments asper the TEMA [Tubular Exchanger Manufacturers Association] standards, ASTM section(VIII)(unfired pressure vessuls), is-4503, is-6088 standards. And asper bs, din standard's and is 2825 is 6088 codes. Shell and Tube Heat Exchanger Quality : JC Equipments having its quality control department [QC Control] testing of all its Shell and Tube Heat Exchanger. Problem and Trouble shooting Shell and Tube Heat Exchanger: JC Equipments are well explained the Trouble shooting of Shell and Tube Heat Exchanger.

Shell Tube Heat Exchanger

Get Price Quote

We are offering shell tube heat exchanger. Our shell type heat exchangers are the most common type heat exchangers used by various industries. The thermal and mechanical design of shell tube heat exchanger makes it widely appreciated.

Shell and Tube Heat Exchanger

Get Price Quote

Janani Enterprises is engaged as Shell And Tube Heat Exchanger Manufacturer, Exporter and Supplier in Tamil Nadu, India. The latest technology, high performance Shell And Tube Heat Exchanger that we provide is result-oriented for process industries and for oil cooling. The tubes used internally are deliberately of various shapes and design to obtain different outcomes. While a few of the tubes may be plain, others may come finned longitudinally or horizontally. Additionally, the tubes can also be of various materials and thermal conductivity. For instance, Janani Enterprises Equipment can be designed from carbon steel, stainless steel, cupronickel, copper or brass. Materials Used And Suitability Shell And Tube Heat Exchanger is made of Copper, S.S,M.S. Tubes with M.S, S.S Shell for different applications as per Customer requirement suitable for Generators, Air Compressors, Inter, after, Coolers Chillers and Chemical Processes. Testing Of Heat Exchanger Owing to the complex nature of the shell and tube heat exchangers, regular inspection of the equipment is necessary. This can help to assess the thickness of the tube walls that are prone to fitting, erosion and corrosion over time. The status of the whole bundle of tubes may be charted and assessed through a thorough inspection with the help of a device known as internal rotary inspection system that functions via ultra sonic testing and also has a non-destructive nature Specifications Design ShellLength up to 20,000 mmWeight up to 20 metric tonnesPressure up to 300 Kg/cm3Temperature up to 1000oCTube Plate Diameter up to 4000 mmThickness up to 400 mm Features Materials we used for Shell, carbon steel, stainless steel sizes up to 20000 mmTubes Copper, Brass, Cupro-nickel, Carbon Steels in sizes from 6 mm to 50 mm OD, Stainless SteelsTube Sheets : Carbon Steel, Stainless Steel, Brass etc.Channels and Cover : Carbon Steel, Stainless Steel, Case Iron, Brass, Mild Steel etc.Gaskets : Rubber, Compressed Applications Chemical, PetrochemicalFertilizerThermal Power plantsRefrigeration PlantsMarine EnginesTurbines, Hydraulic SystemsSugar Machinery.

Shell and Tube Heat Exchangers

1 Per -