Wooden Cooling Tower

Based on the leading-edge cooling technology, the Wooden Cooling Tower, which we offer, is manufactured in confirmation to the set industrial standards. We offer the best Wooden Cooling Tower at the best rates. We are a dependable Manufacturer, Supplier and Exporter of Wooden Cooling Tower. Why Our Wooden Cooling Tower? High cooling efficiencyCompatible sparesEasy maintenanceLow noise Timber : All timber is Pine wood and is treated with Chromate Copper Arsenates. All plywood components are treated marine grade water proof plywood. All sections are fully machined prior to treatment. Structural Framing : Structure is bolted and is designed to withstand all operational loads and wind pressure. Hardware : Hardware such as nuts, bolts, washers, ring connectors etc. shall be Hot dip galvanized steel. Internal Fill & Fill Support : Rectangular Fill splash bars are designed to offer maximum splash and wetted surface in such a manner that it permits no dislocation of splash bars and yet allows them to expand or contract with changes in moisture content of wood without cracking, warping or sagging. Splash bars are supported in GRP grid supporters, which are firmly attached to structural girt members. Drift Eliminators : These are made of treated timber planks supported on grooved treated plywood Eliminator frame in herringbone pattern or PVC in Construction. Casing & Air Inlet Louvers : These will be made of corrugated AC Sheet or FRP Sheet. Tower corners are covered by FRP boards. Casing is water tight sealed. Air inlet Louvers are of corrugated AC Sheets or FRP Louvers. Distribution System : Cross flow towers employ a swamped pan distribution. The open pan covering the entire fill area distributes hot water evenly over the fills by means of PVC nozzles. Fan Deck : The fan deck is of FRP OR MS/HDG Construction with Motor frame & Fan Guard. Fans Dynamically balanced Cast Aluminium Alloy / FRP Fan Motor TEFC-IP 55 With EN -8/9 Shaft & Class F insulation.Direct Drive Ccs Timber Cooling Tower

...more

Water Cooled Chiller

Water Cooled Chiller, which we offer, is manufactured, using world-class scroll compressors that are from Copeland and Danfoss-Maneurop. These Water Cooled Chillers are absolutely Microprocessor Based, making them suitable for any type of processing cooling applications ranging from (+) 20oC to (-) 15oC. Any type of applications demanding working in temperature up to (-) 50oC, refer Brine Chillers. We offer the best sources to get premium Water Cooled Chillers. Highlights CFC Free Refrigerant R- 407CNozzle sizes are at the chiller inlet / outlet.Bigger pump, if chosen, can be located within the chiller, only if possibleStepwise Capacity Control (20%, 50% & 75%)PLC Based Control without Communication. Bigger capacity tank, if chosen, will be external Design Conditions Connected Power 415V AC +/- 10% / 50Hz / 3 Phase + NeutralDesign Condensing Temperature (+) 40oC Design Evaporating Temperature (+) 5oC

...more

Sigma Fills

490 Per Piece

Color : Multi

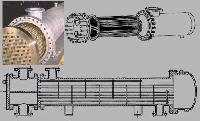

Shell & Tube Heat Exchanger

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact. We are a dependable Manufacturer, Supplier and Exporter of Shell & Tube Heat Exchanger. Also, these Shell & Tube Heat Exchangers are designed as per the leading-edge technology. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Shell & Tube Heat Exchanger, which we offer, can be operated within a temperature range of -40oC to 150oC on either side. However, differential temperature should not exceed 120oC at any point. All the Shell and Heat exchangers can be use pre-dominantly under full vacuum, provided differential pressure does not exceed 3 bar g. Details Type: Fixed Tube Sheet, Removable tube Bundle, U-Tube, Coil in Tank, double PipeCapacity Range : As per Customer requirementShell Diameter : 4� to 125�Tube Length : 3� to 40�Tubes : Plain, Integrally Finned or U-TubeNo of Passes: Single, Double & Four passesM.O.C. Tubes : Carbon Steel, Stainless Steel, Copper, Adm. Brass, Aluminium, Titanium, Tantalum, Hastolloy, Aluminium Bronze, Monel, Duplex, CupronickleShell : Carbon Steel, Stainless Steel, Copper, Monel. Brass, AluminiumChannels : Carbon Steel, Stainless Steel, Gun Metal, Cast Iron, Brass, Cast Aluminium, Alloy Technical Information : All the Shell & Tube Heat Exchanger are constructed with 12 mm OD, 1.5 mm thick glass tubes. These tubes are arranged in triangular pitch of 21 mm. Baffles are provided with 30% cut at a distance of approximately equal to inner diameter of shell. Generally, PTFE baffles are used in Glass shells and PP baffles in Metal Shells. Our Applications DG set for all capacitySpace heatingRefrigerationAir conditioning Power plantsChemical plantsPetrochemical plantsPetroleum refineriesNatural gas processingSewage treatment

...more

Marine Heat Exchanger

The Marine Heat Exchangers, which we offer, are available in the tubular form, or with an integral header tank, and models are available to suit engines of various outputs. This Marine Heat Exchanger is acclaimed for fast cooling of the marine engine. We are a dependable Manufacturer, Supplier and Exporter of Marine Heat Exchanger. Construction This Marine Heat Exchanger has a bundle of tubes, where two cooling circuits meet and exchange the heat. This bundle of tubes could be in the cooling circuit of an engine (Marine Heat Exchanger), the oil circuit (oil cooler) or intake air (inter cooler). There is a boat that we can supply with a heat exchanger to suit from the smallest petrol or diesel engine to large V8 petrol and medium-range diesels; Vertical Mounting with Integral Header Tank Horizontal mounting with Integral Header. We can manufacture the Tank of Marine Heat Exchanger, using modular construction from standard components. Design : As per ASME Section VIII Div. 1, TEMA RCB, IS 2825 & IS 4503. Capacity : As per Customer Requirements/standard Design Material of Construction : Size ranging from 3� to 100� in diameter & 40� (Feet) in length.

...more

Intercooler Heat Exchanger

We have settled parameters in the industry for manufacturing, exporting and supplying quality Intercooler Heat Exchanger. With our state-of-the-art infrastructure and a team of experienced professionals, we ensure only superior quality inter coolers are provided to our clients� at most competitive prices. These Intercooler Heat Exchangers are highly appreciated for their quality features like longer functional life and durability. The quality of the Intercooler Heat Exchanger is checked before they are delivered to our clients so that they meet the standard of the industry. We are engaged in offering quality range of Intercooler Heat Exchanger. Our offered coolers are highly appreciated for its durability, reliability, high efficiency and flawless performance thus highly demanded in the market. These are heavy duty coolers that are used in various industries to release cooling effect to the environment. Our offered coolers are highly appreciated for its durability, reliability, high efficiency and flawless performance. The entire range is fabricated and designed using optimum grade raw material procured from reliable & vendors in order to ensure the quality and high performance. Available in different sizes, shapes and capacities and can be customized as per demands of the clients. Features Effective functioningEasy to use Easy installation

...more

Industrial Chillers

Hydraulic Oil Cooler

Hydraulic Oil Cooler are those devices, which are used to dissipate heat from a hotter object by the continuous circulation of oil through a cooling unit. The oil holds edge over water for cooling purpose because it has high boiling point and it does not conduct electricity. The non-conductance makes oil ideal for use with electrical components. We are the prominent Manufacturer, Supplier and Exporter of unmatched-quality Hydraulic Oil Cooler. Our range of Hydraulic Oil Cooler is available in numerous sizes and length, which starts from 150 mm to 400 mm (Oil passage length per channel). Hydraulic Oil Cooler, offered by us, comprises shallow aluminum dish plates brazed together to form tubes with internal in-line turbulators and external mini-louvered air fans. Owing to the efforts of our qualified professionals, we have been constantly indulged in offering a qualitative assortment of Hydraulic Oil Cooler. These Hydraulic Oil Coolers are extensively used in the area where water is not available for cooling purpose. Further, these Hydraulic Oil Coolers are fabricated using the best quality raw material and latest technology in accordance with the set industry standards. Our team of quality controllers rigorously checks the offered Hydraulic Oil Cooler on various parameters to ensure their faultlessness. Features High durabilityHassle-free performanceCorrosion resistanceMaximum flow handlingDimensional Accuracy

...more

FRP Square Cooling Tower

The FRP Square Cooling Tower, which we offer, is manufactured as per the set industrial standards. Also, we undertake repairing and revamping services of any type of FRP Square Cooling Tower. We offer these FRP Square Cooling Towers at competitive rates to the clients. Highlights Operates on the induced draft counter flow principle operationThe fan creates air movement vertically pulled upwards on tower across the fills in opposition to the water flowHot circulating water enters the water inlet headers and sprays through non clogging PP spray nozzleEven Water distribution Well-designed PVC Drift Eliminators are fitted Reduces Drift LossesHas an Inspection Door Allows easy access for inspection and maintenanceSquare tower can be installed in multi cell also Cooling Tower Capacity : Ranging from 5TR to 600 TR in Single cell and as per requirements of client in multi-cells. Benefits Compact design, corrosion resistant and lightweightDurable service LifeMaintenance freeHigher efficiencyMinimum drift loss of waterNo contamination, due to dust or foreign particlesPiping cost negligible and suitable for small unit Assembly FRP Casing : Cooling Tower Casing is made of selected grade materials of tough Fiber Glass Reinforced Polyster and resins etc. An additional embossing is provided for extra strength of large Cooling Towers.Header Pipes : The header pipe designed for proper distribution of water over the FILLS so that proper contact time for air to water is achieved. The header pipe is manufactured in G.I., P.P. with FRP moulded construction which makes it Non Corrosive Type & Long Lasting.Water Distribution Nozzle : We are offering low pressure drop, non-clogging, ABS make solid cone type nozzle for distributing the water on the fill pack area. Each nozzle is designed to operate on a water fluctuating load as good as 20%. Each nozzle can cater the service area of 1.2m x 1.2m at an inlet pressure of 0.3 kg. Per cm.sq.Drift Eliminator : CCS Drift eliminators, to reduce carry over losses through of moistures drop in the air stream. The individual drift eliminators of s-shaped corrugated sheets are bonded with subsequent layer to creat the structure.PVC Honeycomb Fills : PVC Honeycomb type fills having extended contact area. Splits incoming air and water into several streams spread evenly across the water cross section increasing heat transfer rate easy to replace.

...more

Frp Bottle Shape Cooling Tower

The FRP Bottle Shape Cooling Tower, which we offer, is manufactured as per the set industrial standards. These FRP Bottle Shape Cooling Towers are available in diverse colors to match different requirements of the clients. This FRP Bottle Shape Cooling Tower is manufactured using the leading-edge technology. Highlights Bottle type cooling towers work on the principle of counter flowThe water flows down while the air is pulled upwards via fanAs the water flows further through the system, the air encounters is fresherThe air is cooler and less saturated with moisture Cooling Tower Capacity : Round shape cooling tower gives 100% cooling efficiencies it�s give good appearance flow rate from 5 M³/Hr To 550 M³/Hr gives differences in temperature 4oC To 30oC Availability of Capacities from 10 TR T0 600 TR Benefit Direct access to internal parts, providing easy maintenance and repairF R P Cooling Towers can withstand corrosion, to resist water born bacteria and organismsLight in weight and permits roof installation without special reinforcement of any kindVertical Induced Draft Counter Flow design permits installation in any directionConsumes less power because of less air resistance to waterA directs Driven Axial Fan ensuring the system free from problems faced with Belt & Gear Drives Assembly Sprinkler : Uniform distribution of water over the honeycomb. Fills is achieved by means of automatic water sprinkler. There is no motor but with the jet recoil force to rotate and distribute water located centrally, it consists of several P.V.C Pipes, on which a series of apertures are drilled longitudinally fitted on lightweight. PVC rotary heady and mounted on sealed ball bearings.Drift Eliminator : CCS Drift eliminators, to reduce carry over losses through of moistures drop in the air stream. The individual drift eliminators of s-shaped corrugated sheets are bonded with subsequent layer to creat the structure.PVC Honeycomb Fills : PVC Honeycomb type fills having extended contact area. Splits incoming air and water into several streams spread evenly across the water cross section increasing heat transfer rate easy to replace.

...more

Finned Tube Heat Exchanger

We offer Finned Tube Heat Exchangers, which are designed as per the international standards and requirements of the clients. These Finned Tube Heat Exchangers can be employed for cooling or heating of air or other gases which flow in a duct or cooling of water and other liquids using air. Also, these Finned Tube Heat Exchangers are provided with Aluminium extruded finned tubes. These Finned Tube Heat Exchangers are manufactured with copper, aluminum, stainless steel, admiralty brass, cupro-nickel or carbon steel. Apart from this, these strongly constructed Finned Tube Heat Exchangers are widely used in different applications like air laden with abrasive particles, corrosive fluids and air heating with steam and designed for special custom-built applications. Highlights Rugged construction Corrosion resistant Available with customization High durability Low maintenance cost Trouble-free operation Industrial Applications Food processing Textile SugarDrier Manufacturing Cement plants

...more

Fanless Cooling Tower

Based on the cutting-edge technology, the Fanless Cooling Tower, which we offer, is manufactured as per the set industrial standards. We offer the best Fanless Cooling Tower at the market leading rates to the clients. We are a dependable Manufacturer, Supplier and Exporter of Fanless Cooling Tower. Highlights Power consumption : No fan, higher head required; equivalent total power consumption with traditional water cooling towerSilent design : No fan, motor, reducer, rotating machinery with noise lower than the ultra-low noise cooling towerCooling method : Cooling water spray kinetic ventilation without external power sourceSuspension means: No vibration, no shock absorbers neededOperating and maintenance costs : Composed of static components made of corrosion-resistant materials.No wear and tearLow maintenance charge Working Principle of Fanless cooling tower : Natural Type Cooling Towers are nothing but the water is cooled with natural atmospheric air travelling and the water is sprayed with the help of Spray nozzles and covered with louver covers. This method saves the operating cost because it has no mechanical fans. These cooling towers are called as atmospheric cooling tower or Fanless and fillless cooling tower. (Available range is from 7.5 TR to 100 TR) Splash loss and dust prevention capacity : Five-fold water blocker installed at the air vents of the tower top for liquid-water separation. In addition to dust prevention, the water splash loss is between 0.001~0.009% (as per spray pressure). Reduce more than 90% water splash loss than the traditional tower and reduce the transmission of Legionella bacteria Material of Construction Structure : Is made from lined with FRP for corrosion resistance with heavy M.S.Angle/Tee/Channel sections and hot dipped galvanised orLouvers : Are made from fibreglass reinforced plastics which ensures corrosion resistance and good mechanical properties.Water Distribution Headers : Are made from �c� class galvanised pipe.Nozzles : Are made from nylone-6 to give good corrosion resistance.Nuts& Bolts : Are made from nylone-6 & M.S. Electroplated.

...more

Dry Cooling Tower

Also known as Indirect Closed Loop, the Dry Cooling Tower, which we offer, is used for closed-circuit cooling of the water. This Dry Cooling Tower does not have any contact with water. We are a dependable Manufacturer, Supplier and Exporter of Dry Cooling Tower. These Dry Cooling Towers are available in a capacity ranging from high to low capacity, based on the clients� requirements. Also, we render Services related to Dry Cooling Towers. Construction : A structure in which water is cooled by circulation through finned tubes, transferring heat to air passing over the fins; there is no loss of water by evaporation because the air does not directly contact the water. Benefits of Dry Cooling Tower Elimination water consumptionElimination of maintenanceTo make improved efficiencyBalanced Full loadVery Easy to installCooling by air at no extra costStay away from pollutionTough fibreglass casing or SS 304Hot dip galvanized / epoxy coated structureIP 55 protected flange mounted variable speed motorAerodynamically designed axial flow type, energy saving fan in FRP / Al. Alloy constructionAluminium finned copper tube coilElectrical & temperature controlsS. S fasteners Applications Fertilizer plantsChemical and petrochemical plantsDairies and defense factoriesAutomobile industryCement and sugar industriesMachine tools manufacturing unitFurnaces manufacturing unitDiesel gen-set manufacturing unitAir gas compressors manufacturing unit.Power plants

...more

Copeland Scroll

Brand Name : COPELAND

Model Number : ZR-49

Conventional Plate Heat Exchanger

We are among the leading Manufacturers, Suppliers and Exporters of Conventional Plate Heat Exchanger to the esteemed clients. These Conventional Plate Heat Exchangers are available in various types� Water Jacket Type, Fins Type and U Tube Type. These Conventional Plate Heat Exchangers are suited for aviation and aerospace applications, including engine cooling. These Conventional Plate Heat Exchangers are procured from reliable Vendors in the market and advanced technology. These Conventional Plate Heat Exchangers are available at competitive rates in the market. A Plate Type Heat Exchanger is a type of Heat Exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a Conventional Heat Exchanger in that the fluids are exposed to a much larger surface area because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. It is not as common to see Plate Heat Exchangers because they need well-sealed gaskets to prevent the fluids from escaping, although modern manufacturing processes have made them feasible. Technical Data Heat exchange surface per plate : 0. 04 � 2. 50 m²Max. Design pressure : 25 barMax. Design temperature : 170oCPlate Material : 304, 316L, 310S, 254MO, C-276, TA1, N6 Applications Heat Exchangers are suited for aviation and aerospace applications including engine coolingIn automotive or industrial truckFor heating and cooling water for domestic purpose (e.g. swimming pools, snow melting, and boilers)Designed to cool electronic components that generate high amount of heat (CPUs, Lasers, and Transformers)In food, Dairy and brewing industriesFor heating, ventilation and air conditioning (HVAC) applicationsFor Heating and cooling of hydraulic power fluidFor Oil heating and cooling applicationsSuited for marine or shipboard applicationsSuited for power generation applicationsFor compressed air and are designed for use in pneumatic systemsFor use with refrigerants in cooling systemsSuited for applicants that involve the transfer of heat to and from steamOther unlisted or specialized applications

...more

Brazed Plate Heat Exchanger

Brazed Plate Heat Exchangers, which we offer, are designed Brazing the Stainless Steel Plates together, thereby eliminating the need for Sealing Gaskets and thick frame plates. As well as for holding the plates together at the contact points, the brazing material seals the package. Baode's Brazed Plate Heat Exchangers are brazed at all contact points, ensuring optimal heat transfer efficiency and Pressure resistance. The plates are designed to achieve the longest possible lifetimes. Material Of Construction : The BPHE�s (Brazed Plate Heat Exchanger) main components are Stainless Corrugated Plates and Copper Sheet. These Stainless Steel Plates are brazed together by brazing material (Copper or Nickel) in Vacuum furnace. Copper Brazed Heat Exchanger can be used for numerous of applications. However, for food or applications, involving aggressive fluids, Nickel brazed units are recommended. Principle In Brazed Plate Heat Exchanger : The basic flow principle in out Brazed Plate Heat Exchanger is parallel (except dual system BPHE) and current flow; this design can achieve the most efficient heat transfer performance. Normally the connections are located on one side of the heat exchanger, this design makes them easier to install. Multipass Design : The Heat Exchanger can be designed as a multipass unit according to customers' needs: different connections location and type & size. Customer-specific designs are available; please contact Welltech Cooling Systems for more details. Advantage of BPHE High corrosion resistantHigh pressure resistantHigh thermal efficiency High working temperatureCompactnessLow maintenance Applications CondensersSub coolers EvaporatorsHVAC applicationOil coolersHeat pump, air-conditioning, and chiller

...more

Air Receiver Tank

Material : SS,MS

Storage Capacity : 1000-5000 L

Brand Name : WELLTECH

Tank Orientation : Vertical

Color : White

...more

Air Cooled Chiller

The Air Cooled Chiller, which we offer, is manufactured as per the set industrial standards and norms. We offer premium Air Cooled Chiller at competitive rates to the clients. We are among the reliable sources to get the best Air Cooled Chiller. Highlights Use special compressors from Copeland, Danfoss and Bitzer, having a capacity from 5TR up to 20TR with Single Compressor System Also, Multiple Compressor Systems are availableVaried range of Refrigerants available such as Freon R 22, R 404a, R 407c, R 507, R 134a, etc.Low NoiseLow VibrationLow Failure rateCompact modular design Maximum accessibility Total connectivityReliable and High Efficiency and High Performance Scroll Compressor Tropicalised design for high ambient temperatures up to 52 degree CBrazed Plate EvaporatorWide Choice of Capacities and EfficienciesEasy installationBetter part load efficiency with multiple compressorsPositive pressure designLower electrical infrastructure cost Available with heat pump application

...more

After Cooler Heat Exchanger

After Cooler Heat Exchanger is a Shell and Tube Type Heat Exchanger, which reduces the temperature of compressed Air and as a result Moisture from the Compressed Air is separated. Cooling is done by circulating water from the opposite side of the Compressed Air inlet in after cooler. The After Cooler Heat Exchanger is designed in such a way that the Cooling Water passes through the Shell in turbulent flow, resulting maximum heat dissipation from the Compressed Air and hence more quantity of Moisture is separated in Moisture Separator. This After Cooler Heat Exchanger cools the Water with Moisture Separator from 100 CFM to 500 CFM. Features All dimensions are in MM, unless otherwise statedAll bolts holes to straddle the principal centre line.All tubes to be expanded and make leak proof in tube sheetDrain valve will be provided for moisture separator drainAuto drain valve is optional

...more

Turnkey Project

Welltech Cooling Systems offers hi-tech production setup to execute projects on complete turnkey basis at client�s end. The successful use of advanced production techniques also allows us to bring better cost effectiveness in the services delivered. We, Welltech, are taking turnkey responsibility engineering solutions, including erection, commissioning and testing of complete cooling towers. In the case of concrete cooling towers the civil work is undertaken by us. We have a full-fledged civil design and construction Department with highly trained and experienced civil engineers. We also undertakes contracts for motor control centers, cabling, lighting, lightning protection, earthling, circulating water piping, pumps, water treatment plants, fore protection systems and complex instrumentation in addition to cooling towers. Its scope includes preparing of preliminary reports, framing technical specification, preparing of drawings and site layouts, equipment selection, foundation drawings, design and manufacturing, Erection & commissioning, training of people at site for operating in plants. We have successfully and efficiently executed several prestigious turnkey projects not in India but overseas also within the given time frame. We are seeking vendor registration & look forward to a lasting and meaningful interaction with you.

...more

cooler heat exchanger

Cooling Towers

Frp Cooling Towers

Heat Exchanger

Be first to Rate

Rate ThisOpening Hours