Wood Working Knives

Apex supplies a wide range of Woodworking Knives & Saws to almost 85% of the woodworking industry of India. Apex offers a range of Tungsten Carbide D/D, Beam & Rip Saws, Spindle Moulder Cutter heads, Veneer Peeling & Slicing Knives, Veneer Jointer/Clipper Knives, Pressure Bars etc. Key Benefits Suitable for hard tropical woods & knotty coniferous woods Good results with woods with high resins, knots and pencil logs. Combination of Iron & Special Cladded Steel for greater economy and value for money Dimensionally stable yet flexible. Improved Veneer Quality & Size. Longer life between regrinds and higher regrinders per knife. Uniform edge wear Superior Tungsten Carbide grade for better cutting performance and durability. Suitable for Moulding, Furniture Industry, Laminates, Particleboards, Blockboards etc.

...more

Wire Rod Mill Shear Blades

Apex Shears and Knives are manufactured to suit each application and customer design. They are available in a wide range of standard and proprietary chemistries suitable for either hot or cold work. They deliver the correct combination of toughness, shock resistance, and edge-holding characteristics required for each application. Apex Shears offers FLYING SHEAR BLADES, ROTARY SHEAR BLADES, COLD SHEAR BLADES, HOT BILLET SHEAR BLADES, CCM SHEAR BLADES, ANGLE SHEAR BLADES, ALLIGATOR SHEAR BLADES, CONTINUOUS SHEAR BLADES, CHOPPING SHEAR BLADES, SACK SHEAR BLADES Knives are available in a wide range of materials and are selected and heat treated to match the demands of line environmental conditions, strip characteristics, and shear design.

Material : Alloy Tool Steel

Shape : Rectangular

Color : Metallic

Variety : As per Customer Drawing

Packaging Type : Wooden Cases

...more

veneer slicer knives

Face Veneer for the Woodworking Industry can be divided as under : Longitudinal Slicing: The log is cut into flitch slabs usually between 50 and 100mm thick. The slabs are drawn under the stationary slicer blade end on, and the veneer is paired off down the length of the flitch. Crosscut Slicing: Over the years, more decorative veneer has been produced by this method. It is fast and very efficient, with wastage from each bolt being minimal. In crosscutting, the flitch or full log is locked into the machine. Systems have been developed with stationary or moving knives but the principle is the same. The knife moves across the width of the flitch at a slight angle, and because of its short travel, quick cycle times are achieved with high output. As the flitch is sliced away the carriage gradually moves closer to the blade with a pressure bar controlling the knife position. Staylog Lathe Slicing: This technique can accommodate the quarter cut slicing, crown cut slicing, semi rotary peeling, or highly decorative difficult timbers such as burls, butts, ripple and fiddleback. Because of its flexibility it can maximize the yield of these timbers and is particular suited to cutting smaller logs such as regrowth. The log or flitch is locked into the machine arm which rotates on a centre axis like a lathe. With each revolution the flitch contacts the knife, which cuts across the width of the face. The veneer is sliced off in a tangential arc to the centre axis, and therefore produces veneer which is actually wider than the dimensions of the flitch it came from. This is particularly advantageous when using smaller logs. As the flitch is sliced, both the log arm and knife carriage move together to maintain balance and the correct cutting angle. In addition to being an optimum system for small regrowth logs this technique offers another important advantage over conventional slicing. The staylog lathe has the facility to manipulate the position and angle of the flitch in the slicer, thus avoiding or minimizing impact of unsound or undesirable sections, or conversely taking advantage of the better sections. Apex has an extraordinarily broad and comprehensive range of products for plywood and veneer industries. Apex's factories can supply virtually all types of knives and knife-related components. First-class raw materials, professional heat treatment for good wear resistance and precise machining for dimensional accuracy with blemish-free surfaces for superior cutting performance and quality of end products. The steel for these knives is specially rolled under the technical guidance of Apex's own engineers. The inlay material for the veneer knives are again manufactured from wide range of steels such as AISI 01, S1, HSS M2 and Solid Steel Knives from special grades of steel such as 8% Chrome Steel.

Type : Face Veneer Slicer Knives

Material : Alloy Tool Steel

Color : Silver

Finishing : Polished

Feature : Attractive Designs, High Strength

...more

Veneer Peeling Knives

Apex has an extraordinarily broad and comprehensive range of products for plywood and veneer industries. Apex's factories can supply virtually all types of knives and knife-related components. Apex Inlaid steels specially developed for Rotary Lathe and Slicer Ap plications for the PlywoodNeneer Industry. Superior Tool performance + Optimal Cutting Characteristics are achieved through well balanced heat treatment & processing. Finished Veneer has to be sufficiently strong, smooth-surfaced and uniform in quality which is only achievable by using high quality slicing and peeling knives. A high quality knife guarantees faultless production and helps reduce raw material wastage which in turn yields savings in terms of overall costs. The steel for these knives is specially rolled under the technical guidance of Apex's own engineers. The inlay material for the veneer knives are again man ufactured from wide range of steels such as AISI 01, S1, HSS M2 and Solid Steel Knives from special grades of steel such as 8% Chrome Steel.

Application : Veneer Core Peeling Machines

Length : All Standard Sizes for e.g. 40”, 42” 56”, 108” etc

Blade Material : Tool Steel/HSS Inlaid Quality

Hardness : As per requirement

Feature : Fine Finishing, Quality Tested

Blade Finishing : Hardened & Ground.

...more

Veneer Peeling Knife

Veneer Clipper Knives

Apex has an extraordinarily broad and comprehensive range of products for plywood and veneer industries. Apex's factories can supply virtually all types of knives and knife-related components. Apex Inlaid steels specially developed for Rotary Lathe and Slicer Applications for the PlywoodNeneer Industry. Superior Tool performance + Optimal Cutting Characteristics are achieved through well balanced heat treatment & processing. Finished Veneer has to be sufficiently strong, smooth-surfaced and uniform in quality which is only achievable by using high quality slicing and peeling knives. A high quality knife guarantees faultless production and helps reduce raw material wastage which in turn yields savings in terms of overall costs. The steel for these knives is specially rolled under the technical guidance of Apex's own engineers. The inlay material for the veneer knives are again man ufactured from wide range of steels such as AISI 01, S1, HSS M2 and Solid Steel Knives from special grades of steel such as 8% Chrome Steel.

Application : Industrial

Length : As Per Drawing

Blade Material : High Alloy Steel

Hardness : As Per Requirement

Feature : Fine Finishing, High Strength

Blade Finishing : Ready To Use

...more

Vegetable Cutting Blades

Apex produces a wide range of custom made circular slicing blades for fruit/ vegetable slicing and chopping as well as for Cheese Slicing and Cutting, Po tato Chip Slicing including Urschel Machine Blades, Bread Slicing Blades, Hammer Mills for Frozen Powders etc.All of these items are made to order against customer specific inquiries and drawings from either SS 420 or SS 440 Food Grade Stainless Steel.

Color : Grey

Finishing : Coated

Shape : Round

...more

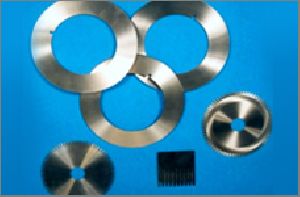

Tungsten Carbide Circular Slitting Knives

Apex Shears offers a wide range of custom-made solid TC Razor Circular Knives for Carton, Paper and Cardboard Industry. Compared to HSS and D2, Tungsten Carbide has many advantages which are suitable for many slitting applications. The most important advantage is very long running life. In many situations, it can be as much as 10 to 20 times as seen in the paper, cardboard or corrugated container industry. The mirror finish provides protection from glue adhering to the knife which in turn protects against knife breakage caused by uneven pressure. The sharper cutting edge produces less dust, making for a cleaner working environment. Although the Tungsten Carbide knife is brittle, the high cobalt content increases overall strength. In addition, the new process HIP, (High Isothermal Pressure) improves knife stability dramatically.

Material : Tungsten Carbide

Country of Origin : India

Application : Tungsten Carbide Razor Knives (TC) For Cutting Paper, Board And Cardboard

Packaging Type : Carton Box

...more

Tube Knives and Blades

Apex is one of the key suppliers to the Indian Automobile Tyre & Tube industry with consistent supplies of precision engineered blades and knives for tyre manufacturing. Key Benefits Sharp, Keen and uniform Cutting Edge Optimally heat treated and precision ground. Trouble free operation. High quality Stainless Steels and High Alloy Steels ensure optimum performance for years

...more

Tube Cut Off Knives

Apex Shears produces Knives and Saws for any cutting or trimming applications in pipe and tube making lines as well as upstream and downstream operations. ALPHA SHEAR BLADES are the CUT-OFF KNIVES for cutting profiles and tubes. The cutting effect of alpha cutters is achieved with combination of high pressure and high speed. Burr free cut of highest precision should be achieved and the cut profile should be free of deformation. Very short cutting times enable using these alpha cutters shear blades not only in stationary machines, but also in production lines during continuous cutting. In standard modification Alpha Cutters - alpha shear blades are made with PVD coating to prolong their lifetime, decrease friction coefficient and to avoid cool surfacing. These tools aren't standardized at all, that's why they are always tailored. For making the offer sending the drawing or sample is enough. Unlike abrasive wheels, which hack a path through materials and generate heat, smoke and debris that can contaminate hydraulic cutting systems, these punch type tube cutter are impact cutting and hardened blades to slice cleanly through the work eliminating large volumes of waste. Raw materials used in manufacturing of Alfa cutters for tube cutting and profile cutting is made from imported high speed steel [HSS m2] and moves up and down at high speed for throughout the cutting process. Hardness retention is a very key factor in designing a Alfa cutter for tube and profile cutting since the cutting operation is applied in hot applications. We use high quality steel which has to pass all quality test before its used to manufacture Alfa cutter for tube cutting and profile slitting. High Speed Steel is used due to its property to sustain high operating temperatures without losing its temper (hardness) allows Alfa cutter in punch type tube cut off slitting process and to cut faster than other tool steels. We welcome your drawings/designs for our consideration!

Material : High Speed Steel (HSS M2)

Shape : Rectangular, Triangular, Circular

Application : Industrial Use

Color : Metallic

Variety : Hardened, Ground, Ready to use

Feature : TiN Coated/Uncoated as per requirement

...more

Tissue Knives and Blades

Apex group are the market leaders for sales of Knives & Paper Mill Knives in India with an over 58% market share in 2007-08.

...more

Tissue Cutting Circular Log Saw Blades

Apex Shears manufactures Circular Tissue Cutting Log Saw Blades for various machine types for e.g. PERINI, PCMC etc. These are manufactured from different steels such as DIN W.Nr 1.3505, or the Popular DIN W.Nr 1.2379. Apex also supplies log saws from HSS DIN W.Nr 1.3343 on request. These saw blades are perfectly smooth, finely ground and balanced for opti¬ mum performance and can be supplied with surface coatings as per the customers requirements for e.g. with XYLAN™ or TEFLON™ coatings.

Color : Grey, Silver

Shape : Round

Finishing : Polished

Diameter : 300mm, 610mm, 800mm, 1000mm Etc.

...more

Tct Circular Saw Blades

Apex Shears has an extraordinarily broad and comprehensive range of products for Paper, Paperboard Industry. Apex's factories can supply virtually all types of cutters, knives and knife-related components.Apex's Knives are manufactured using alloy steel grades like SAE 52100, AISI D2, D3, 01, 07 and AB. Knives from CPM 10V are also sup plied on request.Slitter Knives up to 500mm in Diameter are also manufactured from HSS Steels such as DIN W.Nr 1.3343 (M2), and Powder Metal HSS such as ASP 2023 and ASP 2053.Apex also supplies INLAID qualities for Bottom Knives, Sheeter Knives, Guillotine Knives etc. These Knives are inlaid with Alloy Steel, High Speed Steel (HSS AISI T1) or Tungsten Carbide.Knives for standard machine makes such as Polar, Seypa-Perfecta, Wohlenburg, Sudarshan, Lineomatic, ltoh, Schneider-Senator, Muller Martini,SDV-1 etc are all regularly supplied to customers worldwide.Apex's Multiple Knife Blocks are manufactured up to 550mm in diame ter with single/double cutting edges with dynamic balancing for high speed slitting.Apex Shears' offers "Total Tooling Solutions" for your requirements!

Application : Industrial

Color : Grey

Shape : Round

Thickness : 2.5 mm

Diameter : 8 Inch

...more

Steel Cord Shredder Knives

Apex Shears offers a wide range of Shredding Tooling and Knives for Plastics, Aluminum, Rubber Shredding/Recycling Knives as well as Wear Parts. Apex Shears begins with selection of the finest high quality steel grades that are selected with great accuracy. These steel grades range from tough medium alloy tool steels to long life high carbon high chrome steels and special high wear resistant steel grades . Our Steel Grades for these Shredding Knives ranges from Carbon Steels to Alloy Steels and also to High Alloy Tool Steels depending on the application Our experienced engineers select the knife material on the basis of your machines/equipment and the material being cut. Our Heat Treatment processes and Through-Hardening Techniques have been perfected with over 60 years of manufacturing experience to enhance the strength, durability and perfor¬mance of our knives. Thereafter these knives are ground using superior grinding machines and techniques to give a proper surface finish, clean sharp cutting edge for durability, performance and superior shred quality. We also manufacture shafts for single shaft/double shaft designs for the shredding machines as well as the metal spacers that may be required by our customers

Material : High Alloy Steel

Application : Industrial Use

Color : Silver-Grey

Feature : Hardened & Ground

Packaging Type : Wooden Cases

...more

Shredder Knife

Sheet Cutter Knives

Apex Shears has an extraordinarily broad and comprehensive range of products for Paper, Paperboard Industry. Apex's factories can supply virtually all types of knives and knife-related components. Apex Shears’ Knives are manufactured in almost all popular sizes with lengths up to 4.5meters and diameters up to 800mm in a single piece using alloy steel grades like SAE 52100, AISI D2, D3, 01, 07 and AS. Knives from CPM 1OV are also supplied on request. Apex also supplies INLAID qualities for Sheeter Knives, Guillotine Knives etc. These Knives are inlaid with Alloy Steel, High Speed Steel or Tungsten Carbide.

Material : Alloy Tool Steel, High Speed Steel

Application : Industrial Use

Color : Silver-Grey

...more

shear machine blades

Material : Alloy Tool Steel, High Speed Steel, Carbide

Shape : Rectangular

Color : Metallic, Grey

Variety : Steelastic/VMI Etc.

Packaging Type : Plywood Packing/Carton Packing

...more

scrap chopper blades

Apex Shears and Knives are manufactured to suit each application and customer design. They are available in a wide range of standard and proprietary chemistries suitable for either hot or cold work. They deliver the correct combination of toughness, shock resistance, and edge-holding characteristics required for each application. Knives and Blades for specialized applications can be designed on request.

Type : Hot & Cold Working for Shearing Scrap Steel

Material : Hot & Cold Working for Shearing Scrap Steel

Shape : As per drawing

Usage : Industrial

Color : Metallic

Variety : Hardened, Ground, Ready to Use.

Packaging Type : Wooden Cases

...more

Score Cutting Knives

Material : Alloy Tool Steel, High Speed Steel

Shape : Circular

Application : Industrial Use

Color : Metallic

Variety : Double Edge/Single Bevel Edge/Toothed

Feature : Sharp Edge

Packaging Type : Plywood Packing/Carton Packing

...more

Rubber Tyre Shredder Knives

Apex Shears offers a wide range of Shredding Tooling and Knives for Plastics, Aluminum, Rubber Shredding/Recycling Knives as well as Wear Parts. Apex Shears begins with selection of the finest high quality steel grades that are selected with great accuracy. These steel grades range from tough medium alloy tool steels to long life high carbon high chrome steels and special high wear resistant steel grades . Our Steel Grades for these Shredding Knives ranges from Carbon Steels to Alloy Steels and also to High Alloy Tool Steels depending on the application Our experienced engineers select the knife material on the basis of your machines/equipment and the material being cut. Our Heat Treatment processes and Through-Hardening Techniques have been perfected with over 60 years of manufacturing experience to enhance the strength, durability and perfor¬mance of our knives. Thereafter these knives are ground using superior grinding machines and techniques to give a proper surface finish, clean sharp cutting edge for durability, performance and superior shred quality. We also manufacture shafts for single shaft/double shaft designs for the shredding machines as well as the metal spacers that may be required by our customers

Type : Rubber Tire Shredder Knife & Allied Tooling

Application : Industrial Use

Color : Metallic

Variety : Multiple Teeth

Feature : Sharp

Packaging Type : Wooden Case

...more

Rubber Mulch Shredder Knives

For our Plastics, Aluminum, Rubber Shredding/Recycling Knives and Wear Parts, we start with selection of the finest high quality steel grades that are selected with great accuracy. These steel grades range from tough medium alloy tool steels to long life high carbon high chrome steels and special high wear resistant steel grades .Our Steel Grades for these Shredding Knives ranges from Carbon Steel 9Cr Si to alloy steel 42CrMo and also to High Alloy Tool Steel AISI D2/SKD11 Grade Steel.Our experienced engineers select the knife material on the basis of your ma chines/equipment and the material being cut. Our Heat Treatment processes and Through-Hardening Techniques have been perfected with over 55 years of manufacturing experience to enhance the strength, durability and perfor mance of our knives.Thereafter these knives are ground using superior grinding machines and techniques to give a proper surface finish, clean sharp cutting edge for durability, performance and superior shred quality.We also manufacture shafts for single shaft/double shaft designs for the shredding machines as well as the metal spacers that may be required by our customers

Type : Rubber Mulch Shredder Knives

Application : Industrial Use

Color : Metallic

Variety : Multiple Teeth Edge

Feature : Sharp

Packaging Type : Wooden Cases

...more

Rotary Belt Slitter Blades

Material : Alloy Tool Steel

Shape : Circular

Color : Metallic

Variety : Calemard, Troester, Muller, Steelastic, Konstrukta, Fischer, Mitsubishi

Packaging Type : Plywood Packing/Carton Packing

...more

Rotary Lathe Knives

Apex has an extraordinarily broad and comprehensive range of products for plywood and veneer industries. Apex's factories can supply virtually all types of knives and knife-related components. Apex Inlaid steels specially developed for Rotary Lathe and Slicer Applications for the PlywoodNeneer Industry. Superior Tool performance + Optimal Cutting Characteristics are achieved through well balanced heat treatment & processing. Finished Veneer has to be sufficiently strong, smooth-surfaced and uniform in quality which is only achievable by using high quality slicing and peeling knives. A high quality knife guarantees faultless production and helps reduce raw material wastage which in turn yields savings in terms of overall costs. The steel for these knives is specially rolled under the technical guidance of Apex's own engineers. The inlay material for the veneer knives are again manufactured from wide range of steels such as AISI 01, S1, HSS M2 and Solid Steel Knives from special grades of steel such as 8% Chrome Steel.

Material : Metal

Application : Industrial Use

Color : Grey

Pattern : Plain

Finishing : Polished

Hardness : 50-70 HRC

...more

Rewinder Top Knives

Apex's Knives are manufactured in almost all popular sizes with diameters up to 800mm in a single piece using alloy steel grades like SAE 52100, AISI D2, D3, 01, 07 and AS. Knives from CPM 10V are also supplied on request. Slitter Knives upto 400mm in Diameter are also manufactured from HSS Steels such as DIN W.Nr 1.3343 (M2), and Powder Metal HSS such as ASP 2023 and ASP 2053.Apex's Multiple Knife Blocks are manufactured up to 550mm in diameter with single/double cutting edges with dynamic balancing for high speed slitting. Apex Shears also supplies INLAID qualities for Bottom Knives, Sheeter Knives, Guillotine Knives etc. These Knives are inlaid with Alloy Steel, High Speed Steel or Tungsten Carbide.

Finishing : Polished

Condition : New

Country of Origin : India

...more

regrinding services

Do you need to regrind some hard material? If your answer is yes, then you have come to the right place. At M/S Apex Shears Private Limited, we are engaged in the business of offering the most reliable regrinding services to the clients across Dehradun (Uttarakhand, India). We have a variety of knives and blades in our product assortment. These knives/ blades are used for the regrinding of the items that we get. The regrinding process is conducted by our well-trained and meticulous experts, who are well-versed with the diverse techniques of regrinding. So, reach out to us now!

...more

After sales Services

M/S Apex Shears Private Limited is a renowned organization that is instrumental in offering reliable and excellent after sales services to the clients across Dehradun (Uttarakhand, India). We believe that after rendering the services to the clients, it is very important to get their feedback and improve accordingly. Therefore, we give special emphasis to after sales services. Once our knives and blades are sold in the markets, we follow-up with our clients or buyers and ensure that they are completely satisfied with our products and services. We follow their suggestions and take their feedback seriously to offer them even better the next time. So, avail our solutions now!

...moreOpening Hours