Psa Nitrogen Generator

Working Pressure Swing Adsorbtion Systems - Air is passed under pressure through vessel containing an adsorbent bed of Carbon Molecular Sieve that adsorb oxygen leaving Nitrogen to go through, part or all of the oxygen will stay in the bed, and the gas coming out of the vessel will be enriched in nitrogen. When the bed reaches the end of its capacity to adsorb nitrogen, it is then regenerated by reducing the pressure, thereby releasing the adsorbed oxygen. It is now ready for another cycle of producing nitrogen. PSA method is recommended for higher purities and customers typically recover their investment cost in as little as 1 year.

...more

membrane nitrogen generator

Working Membrane Systems - Membrane nitrogen generators are suitable for applications requiring medium to low purity up to around 99.9% and for very high flow rates, as high as 5,000 m3/hr from a single generator. Membrane generators when compared to PSA offer benefits such as compact footprint, lower air-to-nitrogen ratio and lesser frequent maintenance. Thousands of hollow fibers are bundled and encased to form a high performance gas separation module which permeates oxygen, water vapor, and other impurities out of its side walls while allowing Nitrogen to flow through its center and emerge as product. Membrane technology is recommended for higher flow rates with minimal maintenance.

...more

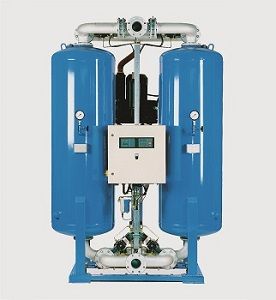

Heatless Adsorption Air Dryer

Working Heatless Desiccant Air Dryers remove water vapor from compressed air through a process known as Pressure Swing Adsorption.A solid state controller automatically cycles the flow of compressed air between the towers, while the "online" tower is drying, the "offline" tower is regenerating. Regeneration, sometimes referred to as purging, is the process by which moisture accumulated during the "online" cycle is stripped away during the "offline" cycle. As dry low pressure purge air flows gently through the regenerating bed, it attracts the moisture that had accumulated on the surface of the desiccant during the drying cycle and exhausts it to the atmosphere. Our offered Heatless Adsorption Air Dryer is acknowledged among our clients its compact design, low maintenance cost and robust structure. Benefits Due to its inherent simple design, investment in this type of dryer is the cheapest and the payback on this investment is very quick. Low temperature operation reduces corrosion in towers and desiccant lasts longer. Power requirement is 60 watts only for solenoid valves operation.

...more

Nitrogen Tyre Inflator

PSA technology NTYRE PSA nitrogen series is based on pressure swing adsorption technology which includes Adsorbent bed and storage tank sufficient to inflate number of tyres at once. Pressure swing adsorption (PSA) is a technology widely used to separate some gas species from a mixture of gases under pressure according to the species' molecular characteristics and affinity for an adsorbent material. Carbon Molecular Sieves as adsorbent is used in Nitrogen separation from air at high pressures. Membrane technology NTYRE Membrane series is based on membrane technology. Thousands of hollow fibres are bundled and encased to form a high performance gas separation module which permeates oxygen, water vapour, and other impurities out of its side walls while allowing Nitrogen to flow through its centre and emerge as product. We offer highest quality membranes of UBE (Japan). Unique key features Fully automatic on site nitrogen Generation system. Highly efficient Filtration System. Integrated storage tank for hassle free supply of Nitrogen Gas. On line Oxygen/ Nitrogen percentage Indicator. 15.6” LED screen to display various advantages of Nitrogen Gas Tyre inflation. Adjustable pressure setting. Separate Key for Deflating tyre. Minimal Maintenance and Extended Life. Automatic tyre counter with password protection. Two digital read outs: SET pressure & TYRE pressure.

...moreBe first to Rate

Rate ThisOpening Hours