adsorption dryer

Get Price Quote

This is the simplest type of Air Dryer with Activated Alumina Molecular sieves Drying agent. Investment wise also this is the cheapest. This design is virtually maintenance free, fully automatic, and requires no attention for years. Cold regeneration type dryers do not require any heating for re-generation and therefore are very simple in design and smooth in operation.

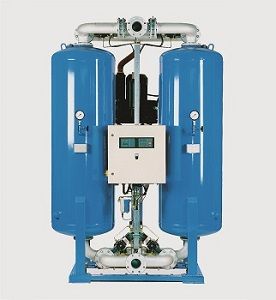

Adsorption Air Dryer

Get Price Quote

Heat regeneration adsorption air dryers are used when one needs compressed air of very low Dew point of (-)60oC or (-)80o Deg C. In this design, the desiccant is regenerated at higher temperature, along with small quantity of Dry air purge. Due to purging with Dry air and thermal regeneration, residual moisture loading on desiccant becomes low and this gives very low Dew point. The Drying unit has 2-vessels filled with Activated Alumina or Molecular sieves desiccant. One vessel remains in drying cycle for 4 hours, while other vessel is simultaneously regenerated at atmospheric pressure. Around 3% flow of dryer capacity is used as purge for regeneration. Electrical heaters are provided in a central finned Stainless steel pipe in both drying vessels. Heating cycle is for 2 hours and in this time hot purge air increases desiccant temperature to around 100oC. At this temperature regeneration is complete (due to dry air purge). Dew point achieved is around (-)40oC. If still lower Dew point is required, air purging rate is slightly increased to 5% for (-)60oC and to 7.5% for (-)80oC Dew point.

Best Deals from Adsorption Dryer

Heatless Adsorption Air Dryer

Get Price Quote

Working Heatless Desiccant Air Dryers remove water vapor from compressed air through a process known as Pressure Swing Adsorption.A solid state controller automatically cycles the flow of compressed air between the towers, while the "online" tower is drying, the "offline" tower is regenerating. Regeneration, sometimes referred to as purging, is the process by which moisture accumulated during the "online" cycle is stripped away during the "offline" cycle. As dry low pressure purge air flows gently through the regenerating bed, it attracts the moisture that had accumulated on the surface of the desiccant during the drying cycle and exhausts it to the atmosphere. Our offered Heatless Adsorption Air Dryer is acknowledged among our clients its compact design, low maintenance cost and robust structure. Benefits Due to its inherent simple design, investment in this type of dryer is the cheapest and the payback on this investment is very quick. Low temperature operation reduces corrosion in towers and desiccant lasts longer. Power requirement is 60 watts only for solenoid valves operation.

Adsorption Air Dryer

Get Price Quote

Adsorption Air Dryer, air cleaning products, Drain Valve, condensate sensing

Heatless Adsorption Dryers

Get Price Quote

Heatless Adsorption Dryers, Automatic Float Condensate Drains