Hot Air Dryer

150,000 Per Piece

The major concern of our firm is to deliver a quality content, thus, we check the product quality on several counts at all stages. Headquartered in Delhi(India), we are making available high quality products to every nook and corner of the country.

hot air dryers

Get Price Quote

We, Mix-Well Industries, are one of the leading manufacturers and exporters of high quality Hot Air Dryers. Company offers wide range of Hot Air Dryers which find use and application in Food, Pharma Cosmetic and many other industries. Our Hot Air Dryers are manufactured, using cutting edge advanced technology, finest quality of raw material sourced from the reliable and certified vendors of the industry. Hot Air Dryers are available in various sizes shapes and designs, so as to meet varied needs of the Customers. The special features of our Hot Air Dryer are as under: Designed for uniform circulation of hot air in the drying chamber. Complete with Electric Motor , Thermostate, Starter, Indicator Lamps and Dial Type thermometer. Available in Wide range modals for trays capacity 12,24,48 ,96,120 to 192 etc. Choice of Steam and Electrically heating Size of Tray 16” x 32” x 1.25”

Best Deals from Air Dryers

DEHUMIDIFIER HOPPER DRYER

Get Price Quote

Refrigerated Air Dryer

20,000 Per Piece

Hopper Dryer

Get Price Quote

Hopper Dryer

Get Price Quote

As the name suggests, Hopper Dryer is used for removing moisture content. The Hopper Dryer that we offer is effective in drying plastic materials. By absorbing moisture, Hopper Dryer helps in maintaining the equipment corrosion free. The Hopper Dryer range can be acquired in different technical specifications from us. We are a well-known Hopper Dryer Manufacturer, Exporter and Supplier in Delhi, India. Why Our Hopper Dryer? Designed to perfectionFlawless performanceTested to ensure smooth operationReasonably priced

Refrigerated Air Dryers

Get Price Quote

We are one of the leading Manufacturers & Suppliers of Refrigerated Air Dryers. The Refrigerated Air Dryers are fabricated by our engineers using cutting-edge technology and superior quality parts and components. The Refrigerated Air Dryers supplied by are robustly constructed, sturdy, efficient and durable. Clients can avail quality tested and highly functional Refrigerated Air Dryers from us at competitive prices. Construction & Working : The basic principal of operation of the Refrigerated Air Dryer is the removal of moisture by cooling air to certain preset temperature. The air entering the system enters into the precooler. A Precooler is a heat exchanger where the incoming hot air is being cooled by the outgoing cold air so as to reduce the heat loads for the evaporator and thereby the refrigeration system. When the air is cooled, i.e., when the heat is removed from the air, the water vapour will get condensed. It is easy to remove the moisture as a condensate than the moisture in water vapour state. The air from the precooler enters into the Evaporator. In evaporator the cooling, heat removal is done by the boiling refrigerant requires heat to boil. This heat is evolved from the air. Air is cooled to 2 o 4 c. When the temperature drops, the moisture turns to condensate moisture is a form of water. The air with condensate enters into moisture separator where the moisture is removed with the help of auto drain centrifugal action of air during the centrifugal passage of air, moisture being the denser medium. The refrigerant circuit consists of a compressor, a condenser, a filter dryer, expansion valve or a capillary tube and an evaporator. The low temperature refrigerant vapour enters the compressor. Compressor rises the pressure of the refrigerant. Also the temp of ref. gas. The hot, high-pressure refrigerant enters into the condenser. In the condenser, heat is removed from the refrigerant by circulating cold air using the Fan. The low temperature, high-pressure liquid enters the filter dryer, where the dirt contents are removed. The refrigerant, then passed into the expansion valve, The temperature of the refrigerant leaving the expansion valve will be � 1 C, This low-pressure liquid refrigerant enters the evaporator. In the evaporator, the refrigerant boils and becomes low-pressure vapour. The Vapour enters the compressor and the cycle continues.

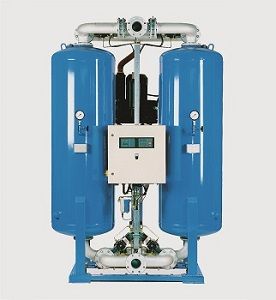

Heatless Adsorption Air Dryer

Get Price Quote

Working Heatless Desiccant Air Dryers remove water vapor from compressed air through a process known as Pressure Swing Adsorption.A solid state controller automatically cycles the flow of compressed air between the towers, while the "online" tower is drying, the "offline" tower is regenerating. Regeneration, sometimes referred to as purging, is the process by which moisture accumulated during the "online" cycle is stripped away during the "offline" cycle. As dry low pressure purge air flows gently through the regenerating bed, it attracts the moisture that had accumulated on the surface of the desiccant during the drying cycle and exhausts it to the atmosphere. Our offered Heatless Adsorption Air Dryer is acknowledged among our clients its compact design, low maintenance cost and robust structure. Benefits Due to its inherent simple design, investment in this type of dryer is the cheapest and the payback on this investment is very quick. Low temperature operation reduces corrosion in towers and desiccant lasts longer. Power requirement is 60 watts only for solenoid valves operation.

Air Dryers

Get Price Quote

Air Dryers, Air Compressors, Pneumatic Tools

Air Dryer

Get Price Quote

Air Dryer, Drain Valve, Water Chiller

Desiccant Type Air Dryer

Get Price Quote

Desiccant Type Air Dryer, Air Compressor, Low Pressure Air Compressor

Air Dryers

Get Price Quote

Air Dryers, Air Compressors, Air Receivers, Lathe Machines, Milling Machines

Air Dryer

Get Price Quote

Air Dryer, Oil Free Air Compressor, Refrigerated Water Bath, Autoclave

Air Dryer

Get Price Quote

Air Dryer, air treatment products, auto drain micro filter

Hopper Dryer

Get Price Quote

Hopper Dryer, Mixer, waste grinder, Die Head for pvc pipe plant

solar air dryers

Get Price Quote

solar air dryers