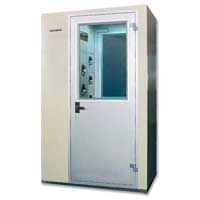

Air Shower

238,500 Per nos

1 nos (MOQ)

Cleanroom Air Shower Unit

Get Price Quote

1 Piece (MOQ)

Air Showers Air Showers are self-contained chambers installed strategically at entrances to cleanrooms and other controlled environments. They minimize particulate matter entering or exiting the clean space to mitigate the risk for cross-contamination. How an Air Shower Works Completely self-contained, pre-wired, fully equipped Air Shower/Tunnel systems help solve decontamination problems Modular design lets you order a system to suit your cleanroom HEPA filter/blower modules (rated 99.97% efficient @ 0.3-micron particles) wash personnel with Class 100 air to dislodge and remove particles Solid-state microprocessor panel provides programmable control over access door operation Interlocking doors minimize contamination, release automatically in the event of power failure Fluorescent lighting is housed in the ceiling for minimal turbulence Available in white epoxy-finished CR steel, stainless steel, or plastic laminate to meet various cleanroom requirements Variety of sizes and door configurations Economical to operate, easy to maintain System options include HEPA-filtered ceiling, ionized grid, and safety glazing These Air Showers and Tunnels offer an effective way to remove surface-deposited particles from personnel—before they get to the cleanroom.

Best Deals from Air Shower

Air Shower

Get Price Quote

Air Showers

Get Price Quote

The air shower is a particularly enclosed outer chamber that works in conjunction with other controlled environments to prevent particle contamination. To remove dust and fibre lint containments from personal or object surfaces, an air shower uses high-pressure, HEPA or ULPA filtered air.

Air Shower

Get Price Quote

A self contained well built factory assembled designed to deliver a spray of moving air from nozzles transported and virtually can be installed at any site. Absolute filter-fan module provide positive pressurization and filtration down to 99.97% efficiency on 0.3 micron. The clean air inside the shower will support a very high degree of sterility and clean air condition. The system is supplied with optionally aluminium grated floor located approximately 6 inches above datum level. Duct air chassis are installed within the walls of the units. While the system is in operation, both doors will be automatically locked. In the event of power failure or an emergency, the doors get unlocked. Construction is of Mild Steel Powder coated Stainless Steel 304 grade.

Tripti Air Showers

Get Price Quote

Tripti Air Showers to deliver a spray of HEPA filtered air at approximately 6000 fpm from adjustable nozzles in the ceiling or opposing walls to departiculate fully gowned personnel just before they enter controlled environments.

Air Shower

2,250,000 Per Piece

1 Piece (MOQ)

Features : Clean air present inside the shower supports a high degree of sterility as well as clean air conditions System supplied with optionally aluminum grated floor placed around 6 inches above the datum level Featuring duct air chassis installed within walls of units The system provided with two aluminum framed glass/acrylic door support with automatic locking device Both doors in an automatically locked position while the system is in operation Provision of unlocking of doors in event of power failure or emergencies Pre-filter support that provides for statically/dynamically balanced air and throwing it through HEPA filter into chamber Statically & Dynamically balanced Motor-blowers with suspension arrangement to reduce noise level for suction and booster Differential Pressure Gauge: 1 No. ON/OFF Switches DOP Test Port 5/15 Amp Switch Socket for external equipment Control Systems – to ensure that both the doors cannot open at the same time & to ensure that both the doors will be locked during the time air flow is on. Timer for setting Air Shower operation time (settable for 30 seconds to 5 minutes) Emergency STOP Straight Entry – Straight Exit / 90o Door Opening Automatic as well as Manual Mode Two Stage filtration : EU6 - Prefilter (95% down to 5 microns) for return air & fresh air intake EU14 - HEPA Filter (99.999% down to 0.3 microns) at the supply position SS 304 doors with double walled flush glass view panels & door closer

Clean Room Air Shower

170,000 Per Piece

1 Piece (MOQ)

Laboratory Cleanroom Air Shower

1 Per Piece

1 Piece (MOQ)

Air Shower

Get Price Quote

Air Shower

Get Price Quote

Air Shower

Get Price Quote

We are the main supplier of this product.

Air Shower MSW-165

Get Price Quote

Air Showers are specialized antechamber which personnel need to pass through before entering clean rooms and controlled environments. Due to the requirement of dust-free conditions in clean rooms or controlled environments, Air showers are used to decontaminate by blasting dust particles off with the help of high velocity HEPA filtered air jets. With the help of high velocity filtered Air pollutants carried by personnel can be removed, the contaminated air then filtered and recirculated again to give clean transfer area. Air showers are very demanding now days for prevention of important manufacturing applications in the field of Micro electronics, Pharma, Semi conductors and are very useful in various types of researches also. FEATURES Available in various sizes according to users requirement. Highly effective HEPA filtered air having cleanliness level as high as 99.99% with cold DOP and 99.97% with HOT DOP retaining air borne particles of size 0.3 micron Pre filter installed before HEPA filter to extended life of HEPA filter. Advance Microprocessor Control System. High efficiency statically & dynamically balanced motor blower assembly. FILTRATION PROCESS High velocity air forced through HEPA filters. Filtered air thrown in the chamber through jet nozzles with high velocity which in turn disperse particulate matter on all surface. Lower portion of the Air showers suck the contaminated air and allow it to pass to blower supply plenum through pre filter installed at base. This process is a continuous process in which air is continuously filtered and recirculated inside the chamber without any exchange with the external environment. MATERIAL OF CONSTRUCTIONS "MAC" Air Shower made up of CRC sheet duly powder coated OR Stainless Steel SS-304 (as ordered) and is designed with a heavy and rigid structure to provide enhanced life of the Equipment. HIGH EFFICIENCY MOTOR BLOWER ASSEMBLY Heavy Duty centrifugal motor blower assembly for high velocity air throw. Compact design energy efficient motor and blower are balanced to give smooth, quiet and vibration free operation. ILLUMINATION ARRANGEMENTS Air Shower chambers are provided with high intensity fluorescent light for uniform lighting throughout the chamber. NOZZLE DIFFUSERS Corrosion resistant, high strength, durable with flawless array of high velocity nozzles for direct high velocity air jets within the chamber. CONTROL SYSTEM The Air Shower system controls the sequential locking and release of the doors, and control the blower. The two doors are interlocked such that two doors cannot be opened at the same time, to prevent pressure losses and cross contamination. Special interlocking feature of our Air Shower system achieve this by preventing simultaneous access of door by ensuring that when one door of Air Shower interlocking system is open then other door is closed before opening of door. Advance Microprocessor controller having Digital LED Display features interlocking system. Both the doors of the Air Shower are interlocked with each other preventing simultaneous access of the door by ensuring that when one door of Air Shower is open then other door is closed. Only one door can be opened at a time to prevent pressure losses and cross contamination. Controller will show "WAIT" to indicate that the other door is open. System controls the sequential locking and release of the door and controls the Blower. Interlocking feature of CFL, UV Tube and blower enables automatic ON of CFL and blower on opening of the door and when door will be closed UV Tube will be ON for sterilizing the cross-over area. Advanced Micro controller based system Delay time between door opening is 4 Sec. Inbuilt sensor Magnetic Lock to read door feedback. Door status indication with high intensity Bar LEDs Status indication " GO, WAIT, DOOR OPEN, CLOSE DOOR Buzzer output for door kept open more than specified time from 2 min. UV Lamp controlling UV Lamp On for both doors closed UV Lamp OFF for both doors open CF Lamp controlling CF lamp ON when any door is open CF Lamp OFF for both doors Closed

Cleanroom Air Shower

25,000 Per Piece

1 Piece (MOQ)

Air Shower

Get Price Quote

Air Shower (PLT-275 E) APPLICATIONS OF AIR SHOWER Air Shower is a specialized chamber incorporated either as entryways of laboratories and other controlled environments to reduce particle contamination (or) kept before the exit of a highly infectious place to stop the contamination. Air showers utilize high-pressure, HEPA- or ULPA-filtered air to remove dust, fibrous lint and other contaminants from personnel or object surfaces. The forceful "cleansing" of surfaces prior to entering clean environments (or) leaving contaminated environment reduces the number of airborne particulates introduced. Tanco manufactures this highly complex and technically advance variant of Air Shower. Not too many companies in the world manufactures Air Showers which requires very high level of technical expertise. Tanco’s Air Shower come with interlocking mechanism which prevent the 2 doors to open simultaneously at the same time. Thus preventing the contaminated air from entering inside the Air shower chamber. Tanco Air showers are frequently used in research laboratories around India and are exported to the worldwide market mainly American and European markets. SALIENT FEATURES & CONSTRUCTION OF AIR SHOWER Outer Chamber is made up of MS powder coated The inner chamber is made up of Stainless Steel (304 grade). Between the outer and inner body wool is stuffed for insulation and for the prevention of thermal loss Door Gasket is provided for proper sealing along with heavy hinges and door closing device Heating elements are made up of high quality Nichrome Kanthal wire are embedded around the chamber Supplied with 1 (or) 2 removable shelves Temperature is controlled by Electronic Digital temperature indicator and is fitted in front for easy visibility Temperature is displayed on digital LED Front panel beside the temperature display also includes the ON/OFF switch Supplied with chord and Plug Operating Voltage: 22 Volts AV (50 Hz)

Air Shower

Get Price Quote

We design, fabricate and install air shower for clean room personnel. These clean room air showers are especially used in different kinds of laboratories, pharmaceutical industries and animal facilities; where they act as entry systems that decontaminate personnel before entering into clean environment. Our engineering team carefully designs and configures an air shower that meets your specific working conditions. Tunnel and conveyor type units are also constructed for carts, equipment and cargo etc. We in-house construct air shower; therefore, we offer our customers facility to order according to their specific requirements. Our air shower units are available in different design configurations and material of construction. Our air shower prices are competitive, quality is unmatched and each unit is covered with excellent warranty terms.

Air Shower

250,000 - 450,000 Per pcs

a) size 1600 (w) x 2100 (h) x 1220 (l) b) 18g - ss 304 fabrication c) pre filter 20 mic d) fine filter 10 mic e) hepa filter 0.3 mic f) blower : 5000 cfm g) air change per hour : 45 h) ss doors with door closer, glass view panel, handles i) automatic door interlocing j) ss nozels for air spray k) side packing of ss 304 sheets in stallation extra

Air Showers

Get Price Quote

Designed to provide protection from Biological & Particulate contaminations in high traffic areas and entrances of clean Air Laboratories or rooms. Outer made of thick CRC sheet duly powder coated. Dynamically balanced blowers with minimum vibration and noise level draw the air and blow it through High Efficiency Hepa filters accurate down to 0.3 microns with efficiency of 99.97% bacteria free area. Automatic actuating air-shower operation, adjustable time-duration of air-showers, recirculation of uncontaminated air, adjustable air-nozzles, clear acrylic door, solid state control system, provision of fluorescent tube lighting are the main technical features.

Air Shower

Get Price Quote

Use : The air shower, a kind of equipment to clean workshop and factory building, can be used to clean away the dust on human body and goods surface. It also acts as an air lock to prevent unpurified air form entering the clean area. It is widely applied in industries such as electronics, precision instrument, meters, and laboratory, etc. Operation Principle : The pre-filtered air in the air shower is compressed into a static pressure chamber by a low noise centrifugal fan before it is filtered by an HEPA filter and sprayed out from the nozzles. The clean air blown out can clean away the dust attached on human body and goods surface. Characteristics : It is widely used equipment for the purification of a local area. By air-showering it can dispose of the dust on the surface of personnel and objects entering the clean area. In addition, it serves as an air valve to prevent unpurified air from entering the clean area. It can effectively reduce the amount of dust entering the clean area to keep a normal working condition.

Clean Room Air Shower

Get Price Quote

The Personnel Air Shower from Weiber are fully self-contained units, designed to provide complete decontamination solutions for various clean room applications. They are ideally installed at the entrance of a clean room or controlled environment chamber to minimize the entry of dust and particulate matters inside the clean room via the clothes and skin surfaces of the personnel. Our Clean Room Air Showerfeature programmable operating modes for flexible application and microprocessor based controller for precise supervision of the operating parameters. They use highly efficient pre-filters and HEPA filters for maintaining highly sterile working environments and an integrated fan/blower assembly to provide high velocity air streams for maximum scrubbing action against dust and particulate matters adherent on the exposed skin, clothes and material surfaces. 3 types of configurations are available: One side flow: The unit allows one-way operation, with the clean side door locked and the grey side door unlocked at the idle state. This mode of operation helps in controlling the flow of traffic in and out of the clean room for maintaining maximum sterility in the working area. Two side flow: The unit allows both side flows, allowing the Air Showers to be activated in both the directions. The user can exit through the clean room door or the grey side door, without compromising the sanctity of the clean air environment. This mode of operation prevents the egress of harmful contaminants from the clean room to the outside environment, making the unit particularly useful in pharmaceutical industries, animal research laboratories and other applications that require working with harmful and biohazardous substances. Tower flow: the flow is from the upper roof of the shower. The fully automatic operation prevents the need for manual switching on/off of the air shower cycle and the shower time, providing an unmatched ease of use. The incorporated safety features such as magnetically operated interlocked doors, the auto reset feature and an array of alarms and LED indicators for actual and set parameters prevent accidental lockouts and ensure smooth functioning of the unit. High velocity shower jets in excess of 20 m/s ensure efficient scrubbing action to remove particulate matter. Programmable operating modes Solid state programmable microprocessor based controls for various operating parameters Fully washable pre-filters remove around 85% of particulate matters, therefore reducing the load on HEPA filters and increasing their efficiency and life span Highly efficient HEPA filters with around 99.99% filtration efficiency for removing particles as small as 0.3 microns and larger. Floor matting operated switch for sequential operation of the air shower Multidirectional air flow Adjustable air nozzles Permanently lubricated direct drive centrifugal motors and efficient blowers for maintaining appropriate face velocities of the air (6000 ft/min + 20 feet), while producing minimum vibrations and noise (less than 60 db) Indicator lights on both sides of the air shower for regulation of traffic within the cubicle Emergency buttons on both sides of the air shower to prevent accidental lock-outs Interlocked doors minimize any chances of contamination Door interlocks operate on the magnetic system Hinged motor/blower compartment access panels made of coated aluminium Tamper proof junction box, placed on top Emergency switch off button with audible alarm located within the shower cubicle