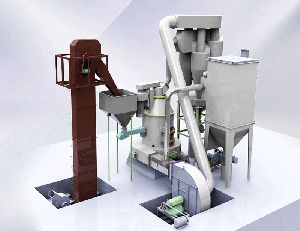

YGMX Series High Pressure Ultrafine Grinder

Details YGMX series high pressure ultrafine grinder could process barite, limestone, ceramic, slag and other non flammable material whose Moh’s hardness is less than 9.3, moisture is less than 6%, it is applied in mining, metallurgy, chemical engineering and construction material industry fine powder process. Advantage Speed Increase 10% Speed of main shaft has been increased positive pressure of grinding is improved grinding area is increased because roller’s diameter is increased and efficiency of grinding is improved. High capacity match up with 1250 mesh single wheel classifier Impeller blade is increased thickness of blade is decreased centrifugal force is increased resistance of powder and air is decreased; rational design of shell of classifier; rational design of air seal coarse particles are kept away from inside impeller final product quality is improved. Air Blower High wind pressure and small flow air blower gas collection tank steel plate thickness is increased rigidity is increased. Main Machine Structure Key parts of main machine are strengthened shock absorption device and air bellow are improved and covering cylinder possesses ground connection vibration damping and anti-crack performance. Product introduction Production capacity : 0.4-18T/H Notice: Mean value the specific production capacity is subject to clients’ actual equipment configuration., 0.4-18T/H Notice: Mean value the specific production capacity is subject to clients’ actual equipment configuration. Processable Material : Power process for limestone calcite fly ash calcium carbide kaolin calcium carbonate coal gangue gypsum slag ore slag coal dust bentonite barite marble talc refractory material. Range of Application : Mining metallurgy chemical engineering and construction material industry fine powder process. YGMX series high pressure ultra-fine powder grinder is the most advanced grinding mill designed by our techniques developing department, it’s widely applied in nonmetal mining industry, it possesses many advantages, such as stable working performance, wide range of application, simple structure, easy operation, high capacity, energy conservation and environment protection, and it’s high technology grinding mill. YGMX series high pressure ultrafine grinder could process barite, limestone, ceramic, slag and other non flammable material whose Moh’s hardness is less than 9.3, moisture is less than 6%, it is applied in mining, metallurgy, chemical engineering and construction material industry fine powder process. In product development and technological innovation field, EMCC not only values the improvement of function, but also pursues efficiency, reliability, stability and persistence. We focus on helping clients to achieve long term and stable benefit. Working principle When main motor power decelerated by gear reducer center shaft and star rack will be forced to rotate roller will rotate around the center shaft under the force of centrifugal at the same time it parallel swings around arm shaft roller will be forced to press on grinding ring to make sure the perfect surface contact between roller and grinding ring. Roller revolves on its axis around roller material will be grinded and crushed grinded powder will be taken to classifier by air blower’s air flow to be classified standard powder will be taken to cyclone collector by air flow then discharged by powder tube coarse powder will fall in the main machine chamber to be

...more

YGM Series High Pressure Medium Speed Grinder

Details High Pressure Medium Speed Grinder is called high pressure grinding mill, and it’s new type grinding mill designed and developed by EMCC designing institute based on many years’ fine powder making machinery manufacturing experience, it is an international leading machine for high efficiency and low energy consumption. Advantage Classifier Precision output size could be adjusted (0.613-0.033mm). Grinding device Eclipsed form multistage seal is adopted excellent seal performance. Spacer protective measures Mainframe is under protection easy to be replaced maintenance cost is reduced. Spring strengthens grinding force Under the effect of spring grinding force that roller impacting on material is increased by 800-1200kg. Product introduction Production capacity : 0.4-35T/H Notice: this capacity is mean value capacity and the specific production capacity is subject to clients’ actual equipment configuration. Processable Material : For grinding and milling limestone calcite fly ash calcium carbide kaolin calcium carbonate coal gangue gypsum slag ore slag coal dust bentonite barite marble talc refractory material. Range of Application : mining industry chemical engineering construction and metallurgy industry over 280 kinds of material fine powder making process. High Pressure Medium Speed Grinder is called high pressure grinding mill, and it’s new type grinding mill designed and developed by EMCC designing institute based on many years’ fine powder making machinery manufacturing experience, it is an international leading machine for high efficiency and low energy consumption. High Pressure Medium Speed Grinder could process barite, limestone, ceramic, slag and other 280 kinds of non flammable material whose Moh’s hardness is less than 9.3, moisture is less than 6%, it is applied powder milling in mining, metallurgy, chemical engineering and construction material industry fine powder process, final product size could be adjusted between 80-425 mesh (finest size could be 1000 mesh), 30-80 mesh coarse powder could be produced by adding a special device. Working principle High pressure medium speed grinder mill hosts 1000-1500 kg high-pressure spring fastening on roller suspender. After working grinding roller rotates around spindle and rolling close to the grinding ring under the high pressure spring and centrifugal force. Its rolling pressure is 1.2 times of Raymond powder machine under the same conditions so the output is much improved. When the material is put into grinding chamber it was grinded between grinding roller and grinding ring the powder was brought into analytical machine by recirculation air from air blower qualified powder was flowed into the cyclone powder collector the large particles was going to regrind. Circulating air return to blower to repeat the above process and the left air entered the Wind bag filter for purification. When the grinding roller and grinding ring reached a certain wear and tear which could ensure a stable yield and fineness under the steady pressure by adjusting the length of high-pressure spring.

...more

Wood Chipper

Details Drum chipper is specialized equipment for high-quality biomass sheet processing, which is applied to all paper mills, particle board plants, fiber plants and wood chip production base, wood chip export base. Advantage Available raw material:Wood logs, branches and twigs with moisture more than 15%. Sperical material blade, with high strength and anti-abrasion. Free of any professional tool sharpener, low maintenance cost. Knife roll is wholistic processing and is undertaken dynamic balance test to improve accuracy and stable operation. It can process larger diameter wood with its special structure. Low power consumption, with is 20-30% lower than similar product in market. Feeding system consists of feeding and squeezing parts: Squeezing part is automatic controlled by hydraulic system; PLC controls the whole feeding system to guarantee the smooth feeding. Forging dead plate, with high strength and long service time. Product introduction Production capacity : 4-70 m3/h Range of Application : Wood logs, branches and twigs with moisture more than 15%. Drum chipper is specialized equipment for high-quality biomass sheet processing, which is applied to all paper mills, particle board plants, fiber plants and wood chip production base, wood chip export base. The slicer can cut logs, small diameter wood and other material into high-quality industrial wood chips with uniform length and thickness and flat cut. It can also cut branches, plates, etc.. Working principle The slicer can cut logs, wood branches, slab, waste veneer, bamboo, cotton stalks and other non-wood fiber stalks into certain specification sheet material, which can be material of particleboard, fiberboard, non-wood-based board and paper. It has advantages such as advanced structure and high quality sliced product, strong materials adaptability and easy operation and maintenance. This machine is composed of base, blade roll, upper and lower feed rollers, conveyor belts, hydraulic system and other components. The welded base that made of high strength steel is support of the whole machine. Two fly knives are fixed onto the blade roll by specially manufactured fly knives and pressure blocks. According to different raw material thicknesses, the upper feeding assembly can up and down within certain range by means of hydraulic system. Qualified flakes falling down through the mesh sieve and large flakes will be re-cut in the machine.

...more

Vibrating Feeder

Details Vibrating feeder is for feeding block material for crushing and screening machine. It is divided into steel plate structure and grate structure two types; steel plate structure vibrating feeder is applied in stone and sand production line, grate structure vibrating feeder is for coarse screening material to make whole system more economical, it’s an essential machine in the crushing and screening line. Advantage Grate Grate clearance is adjustable according to requirement backplate is removable to simplify maintenance and lengthen service life. Gear High strength and high high precision gear make stable working of machine Motor Famous motor brand clients can choose Siemens brand Oil quantity display Clients can check the position of lubricating oil Product introduction Production capacity : 30-800T/H Notice: this capacity is mean value and the specific production capacity would be subjected to actual equipment configuration of clients. Processable Material : granite marble basalt iron ore cobble shale bluestone coal cobblestone construction waste. Range of Application : It’s applied in crushing and screening line in metallurgy coal ore dressing building materials chemical industry and abrasive industry. Vibrating feeder is for feeding block material for crushing and screening machine. It is divided into steel plate structure and grate structure two types; steel plate structure vibrating feeder is applied in stone and sand production line, grate structure vibrating feeder is for coarse screening material to make whole system more economical, it’s an essential machine in the crushing and screening line.GZD Series Vibrating feeer adopts vibration motor as the source of vibration, which has features of simple structure, high capacity, low maintenance rate. It can be widely used in the fields of metallurgy,construction, stone crushing, etc..While, ZSW Series Vibrating feeder adopts eccentric block as the source of vibration, gear drove by turns which has low vibrating noise, smooth operation, long usage. It can also pre-screen fine raw materials which makes higher effiency. The design of adjustable fence can prevent the materials from blocking in the gap. Working principle GZD Series Vibrating feeer adopts vibration motor as the source of vibration which has features of simple structure high capacity low maintance. It can be widely used in the fields of metallurgyconstruction stone crushing etc.While ZSW Series Vibrating feeder adopts eccentric block as the source of vibration gear drove by turns which has low vibrating noise smooth operation long usage. It can also pre-screen fine raw materials which makes higher effiency the designing of adjustable fence can prevent the materials from blocking in the gap.

...more

Vertical Shaft Impact Crusher

Details PCL sand making machine is of high-power and low-consumption which is designed depending on several years hard work and study of mechanical mining equipment. Advantage Unique Lining in Impellers and Vortex Crushing Cavity Unique Lining significantly decreases wear parts cost and maintenance workload. During the process the stone rock can form a protective bottom layer which makes the equipment more durable. Low Dissipation Wear Parts Adopting high-quality wear-resistant materials at home and abroad leads to long service life. Hard wear-resistant material small volume light weight easy to replace. Advanced Spindle Design Bearing special installation and advanced spindle design with characteristics of heavy load and high speed rotation without any problem in fine crushing and coarse grinding. Good Grain Shape of Final Products Final products are cubic shape high density and low iron pollution and can be used as stone shaping machine. Working principle Material from the hopper falls into sand crusher and will be divided into two parts by the distributor. One part falling into the high-speed rotation impeller through the middle and accelerated rapidly within the impeller. That acceleration can be up to several hundred times the acceleration of gravity then projecting out from three uniform impeller flow channel at speed of 60-70 m / s; another part of the material falls freely from all around the feeder impact on the vortex branch cavity lining and then will be bounced back to the top of vortex chamber the movement direction would be changed to start moving down on the diagonal; materials emitters from the impeller form a continuous material curtain. Thus materials will be hit rubbed and grinded twice or several times in whirl crushing cavity. Finally crushed materials discharge from the lower discharge port. Throughout the crushing processmaterials impact and crush each other not in direct impact on the metal element but only shock rub and grind the lining thus prolonging mechanical life. Product introduction Production capacity : 10-500T/h Note: this is only an average value and the specific is subject to the clients’actual equipment configuration in site. Processable Material : Limestone river pebble rocks bluestone cobblestone weathered sand basalt granite quartz diabase. Range of Application : mine cement fire-proof materials bauxite corundum glass raw material building sand stone materials and other metallurgy slag. PCL sand making machine is of high-power and low-consumption, which is designed depending on several year’s hard work and study of mechanical mining equipment. This type sand maker absorbed the advanced technology of the same products of Barmac Company of America, and now is of the international level. It plays an important role in crushing minerals into pieces. Since the sand processing machine was put into production in 2001, EMCC has achieved good market share in domestic market, and product performance is tending toward best perfection, deeply trusted by customers. PCL sand making machine, namely Vertical Shaft Impact Crusher, is widely used in all kinds of mineral, cement, corhart, carborundum grain, glass raw material, machine making construction sand, stone stock and all kinds of metallurgy slag, especially carborundum, sintered bauxite, magnesite, and materials with features of very hardness and anticorrosion. And this and making equipment is more productive than other kind of sand&stone crushers.

...more

TURBO JEEP

We are the main supplier of this product.

Lead Time : IMMEDIATE

Place of Origin : India

Material : Plastic

Model Number : TURBO JEEP

Style : Friction Toy

Supply Ability : 400 Piece/Pieces per Day

...more

Truck

We are the main supplier of this product.

Type : Truck

Material : Plastic

Brand Name : LT

...more

Tipping Counterflow Cooler

Details Counter-flow cooler is newly developed and most advanced pellet cooling equipment. It is mainly used for high temperature pellets cooling after granulation. Advantage The unique rotating well-distributed institution makes the materials more even and the cooling effect more thorough. The pendulum flap discharging institution is controlled by hydraulic system, even and smooth discharging. The discharge speed can be adjustable. It can cool kinds of materials like round, block, piece or pellet status. Low energy consumption and easy to operate. The temperature after cooling will not be over 3 or 5 ℃ of the room temperature. Product introduction Production capacity : 5-30 t/h Counter-flow cooler is newly developed and most advanced pellet cooling equipment. It is mainly used for high temperature pellets cooling after granulation. Working principle The pellets discharged from the pellet mill are of high temperature and moisture. They are fed by a closed air feeder at the top of the cooler. Then the rotating distribution structure disperses the feed evenly in the cooling cabinet. The air blower sucks hot air from the top feed part, while the cold air enters the cooler from the bottom in all directions and pierce into the feed vertically to take away the heat and moisture. Cooling air reverse the pellets and the pellet is cooled from the bottom to top gradually, thus the cooling time is increased, which does good to the production of high quality pellets and to extend the time of pellets storage. Cooling time is controlled by material upper and lower level. When material reaching upper level, the motor is turn on, beginning discharging. But when material lower than lower level, the motor is stopped, stopping discharging. To avoid overflow, the cooler has been provided with an overflow sensor, which stops feeding to the cooler. The pendulum counter-flow cooler is composed of a closed air feeder, air exhaust header, upper and lower feeders, hydraulic controlling system, pendulum flap discharging system and air sucking system, etc.

...more

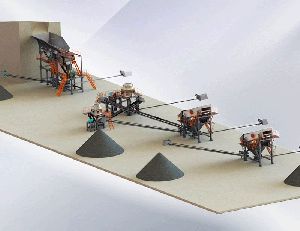

Symons Cone Crusher Gravel Production Line

Details Symons stone crushing production plant configuration is suitable for crushing high hardness stone with finished particle size 3mm-64mm. The particle size can be adjusted according to need. Advantage 1.Big crushing ratioand high capacity; 2.It adoptssteel frame instead of concrete foundation, making installation easy and quick and appearanceWhen you need to move to better production site, the steel frame can also be secondary used. 3. Wearing parts useshigh-strength wear-resistant materialsto enable low loss and long service Product introduction Production capacity : 27-600T / H Note: this is only a average number and the specific value is subject to the clients’actual equipment configuration in site. Processable Material :Gravel crushing process of limestone granite marble basalt iron ore river pebble shale bluestone coal cobblestone construction waste Range of Application : metallurgy construction water & electricity transportation chemical industry building materials industry Symons stone crushing production plant configuration is suitable for crushing high hardness stone with finished particle size 3mm-64mm. The particle size can be adjusted according to need. WKS Symons cone crusher developed by EMCC meets customers’production reqirements and there are two specifications of standard and short head type. Our equipments always pursues efficiency, reliability, stability, durability to help customers achieve long-term an stable income. Working principl Raw materials are screened and carried by vibrating feeder which conveys large materials into jaw crusher equably for primary crushing. Crushed materials will be transported by belt conveyor into WKS Symons cone crusher for fine crushing and then materials enter into circular vibrating screen for screening to distinguish the different specifications of finished product and unqualified gravel will be conveyed into cone crusher to be crushed again.

...more

Symons Cone Crusher

Details Symons cone crusher is a improved machine of PY series cone crusher. It’s applied in above medium hardness all kinds of ore and rock. Compared with PY series cone crusher, it has reliable structure, high efficiency, easy adjustment, low cost and many other advanrages. Advantage Unique Cavity Design Lamination crushing has a great performance on high hardness material even and good final product shape high capacity. Dry Oil Seal Unique dry oil seal can protect machine from dust reliable seal Replacement cycle and service life of parts are lengthened. Overload Protection Spring system is overload protection to protect machine from metel damage.lengthened. Rolling Mortar Wall More material is allowed to be taken into machine and discharge volume is increased. Working principle When working the motor will drive the eccentric shaft to move through the V-beltbig pulley transmission shaft small bevel gear big bevel gear the cone crusher’s eccentric shaft central line will revolve wit the eccentric shaft sleeve. Then the concave will be close then far away from the mantle surface then the material will be circled around the fixed and mobile cone impacted pressed and then curved. After many times of repetition material would be crushed into the desired size then discharged from the lower part. Product introduction Production capacity : 20-600T/H Notice: this capacity is mean valueand specific production capacity would be subjected to actual equipment configuration of clients. Processable Material : granite marble basalt iron ore cobble shale bluestone coal cobblestone construction waste. Range of Application : metallurgy construction white fuel traffic chemical engineering construction material. Symons cone crusher is a improved machine of PY series cone crusher. It’s applied in above medium hardness all kinds of ore and rock. Compared with PY series cone crusher, it has reliable structure, high efficiency, easy adjustment, low cost and many other advanrages. It’s applied in metallurgy, construction, white fuel, traffic, chemical engineering, construction material to process above medium hardness all kinds of ore and rock, it’s the best choice for large scale stone plant and ore crushing.

...more

Superfine Rotor Classifier

Details KX superfine rotor classifier is external circulating new type classifier with rotor and its designed and developed by EMCC. based on rotor type classifier and combined plane eddy flow theory this kind of classifier is designed. Advantage High quality of final product New type high efficiency low resistivity cyclone dust collector makes low resistance and high dust collection efficiency. Longer service life New type lining plate is adopted in all consumable parts easy to maintain and effectively extanding the life of the host machine. Shock absorption device Dustproof -shock absorpting fan minimize the vibration of the whole system Anti knot fell good effect Flexible sweeper is set inside the machine to keep machine clean. Product introduction Production capacity : 16-160T/H Note: This is a mean value capacity and the specific is subject to the clients’actual equipment configuration in site. Processable Material : Limestone calcite fly ash Calcium carbide desulfurization kaolin calcium carbonate coal gangue gypsum water granulated slag fine slag powder coal dust bentonite barite marble talc refractory material. Range of Application : With grinding mill and ball mill to screen final product. Being set up in sand making production line. KX superfine rotor classifier is external circulating new type classifier with rotor, and it’s designed and developed by EMCC. Based on rotor type classifier and combined plane eddy flow theory , this kind of classifier is designed. Proved by practical use, powder classifying efficiency is up to 85%, flexible in fineness adjustment, reliable in performance. Working principle 1.Raw material is taken to the inside of classifier from hopper then falls on the combination propeller bulk plate which combines with rotor under the force of rotation of bulk plate. Material will be diffused to all around under the centrifugal force meanwhile material will be raised by the updraft caused by blade rotation and material boiling will be formed on the bulk plate blade. Finer powder will float and suspend and coarse material will falls down along the cylinder wall. Then the first process will be completed. 2.A lower cage-shape rotor 10 is set under the material diatributing tray. The lower cage-shape rotor rotates along with the principle axis. With the rotating movement vortex flow is formed. Then the coarser and heavier material will be scattered again and the finer material will be raised and returned to the circulating air for another classification. And the coarse powder will be excluded from endocone through trickle device.

...more

Superfine Powder Making Production Line

Details YGMX ultrafine powder mill production line is suitable for processing materials with fineness of finished products in 325-1250 mesh. Advantage 1.With stable operation, the unique structure grading wheel equipped inside the hostmakes good grading effect, ideal particle size, stable product quality and no large particle contamination. It is currently ideal equipment of non-metallic mineral powder dry 2.The rollerand ring adopts special wear-resistant steel, achieving low wearing, long service life and easy maintenance and reducing downtime and replacement 3.The equipment can independently complete the whole production process from raw material crushing equipment, transport, milling to the finished product collection, storage and packaging. 4.Squirrel-cage classifier improvesgrading capabilities and efficiency. Product introduction 0.4-18T / H Note: this is only an average value and the specific is subject to the clients’actual equipment configuration in site. Processable Material :Powder grinding process of limestone calcite fly ash calcium carbide desulfurization kaolin calcium carbonate coal gypsum slag powder bentonite barite marble talc refractories etc. Grinding processing of mineral materials and other more than 280 kinds of materials in metallurgy building materials chemical mining etc. YGMX ultrafine powder mill production line is suitable for processing materials with fineness of finished products in 325-1250 mesh. The YGMX ultra-fine powder grinding mill does not only meet customer requirements for fineness, but also meets the big yield requirements of customers. It not only has the function of product improvement, but also pursues efficiency, reliability, stability, persistence, to help customers achieve long-term, stable income. Working principle After crushed by hammer crusher materials enter into hopper through bucket elevator and then the material inside silo would be evenly taken into YGMX superfine grinding mill by the electromagnetic vibration feeder.Grinded materials enter KX high fine rotor type classifier through the upper spout under the action of windand the dust is purified by pulse dust collector also.

...more

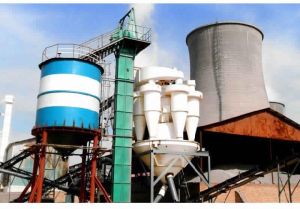

Superfine Ball Mill Production Line

Details MQX ultrafine ball mill powder production line is suitable for ultrafine powder final product with fineness of about 1250 mesh. Advantage 1.Reasonable inlet and outlet designimproves equipment production stability; 2.High manganese steel linerismore wear-resistant and with longer working life; 3.Theclosed cycle of productioncan ensure both fineness and production efficiency; 4.The equipment can independently complete the whole production process from raw material crushing equipment, transport, milling to the finished product collection, storage and packaging. 5.It canalso use special ball mill lining for special industryto get non-ferrous products. Product introduction Production capacity : 0.5-15T / H Note: this is an average value and the specific value is subject to the clients’actual equipment configuration in site. Processable Material : Powder milling production of limestone calcite fly ash calcium carbide desulfurization kaolin calcium carbonate coal gypsum slag powder bentonite barite marble talc refractories etc. Range of Application : This powder production line is for grinding process of non-explosive and brittle materials with low hardness (Moh’s hardness

...more

Spiral Sand Washer

Details LSX spiral sand washer machine can be used for cleaning and separating the powder dust and soil from construction sand. Novel seal structure and reliable transmission of this sand washing device make sure the cleaning effect. Advantage Helical Blade Clever design plays a role in separation of powder and soil in the sand stone. Transmission Device Reliable transmission device makes sure the cleaning effect. Energy-Efficient Greater capacity smaller power consumption easier operation and maintenance and high efficiency. Less Investment and High Benefit Lower price than other series sand washing machine with the same capacity. Working principle The electric motor runs slowly with the impellor after being decelerated by the belt decelerator and gears wheel. The sand and stone flow into washing launder from feeding launder roll with the impellor and grind each other. The impurity covering the sand is washed away. At the same time adding more water the strong water flow will take away waste and some low-weight wastes from washing launder. Through the above process the washing function is finished. The clean sand and stone is lifted up by vane. When it goes up slowly the water begins to drop through the mesh and fall back in the washing launder. On one hand water is removed from the sand and stone; on the other hand the water can be fully used. Finally the sand and stone go to the out launder from the rotary impellor to finish the washing task. Product introduction Production capacity : 100-350T / H Note: this is only an average value and the specific is subject to the clients’ actual equipment configuration in site. Processable Material : Limestone river gravel rocks bluestone cobblestone weathered sand basalt granite quartz diabase. Range of Application : Construction sites gravel plants concrete hydropower dam site metallurgy building materials utilities and other industries washing operations. LSX spiral sand washer machine can be used for cleaning and separating the powder dust and soil from construction sand. Novel seal structure and reliable transmission of this sand washing device make sure the cleaning effect. LSX sand washing machine is usually used with a sand making equipment, and there are two sorts of single spiral type and double spiral type, with features of a high degree of washing, reasonable structure, large capacity, low power consumption, and less loss of sand available. Especially transmission parts of sand washing machine are water and sand isolated, so the failure rate is much lower than the commonly sand washing machine. So it is the best choice for upgrading washing sand industry.

...more

Single Stage Hammer Crusher

Details DPC series single-stage impact hammer crusher is one of the leading products in our company which is widely used to crush limestone stones with medium hardness compressive strength under 200 Mpa and calcium content higher than 40%. Advantage Feed Port Big feed port makes high charging rate. Hydraulic Traction Bar Rear cover could be opened by hydraulic traction bar easy to change impact plate and easy to maintain. Observation Door When machine shut down service condition could be observed. Effecient and Energy-Saving Single stage and high capacity. Working principle DPC series single-stage impact hammer crusher is composed of rotor bearing part discharge dandruff comb strike plate and shell. Hammer of the crusher strikes ore stone ore stone hits impact plate and ore stone impacts each other these are the principle of single stage hammer crusher. Ore stone is fed to feed port by feeder then it will fall into crushing cavity where there are two relative rotating rotors and impacted by hammer to get preliminary crushing. Material will be secondly crushed by rotor and impact plate in the process of falling down then shunted by strike plate to go two mutual symmetry discharge area finally standard material will be discharged by bottom of the machine. Product introduction Production capacity : 70-1000T/H Notice: this capacity is mean value and the specific production capacity is subject to clients’ actual equipment configuration. Processable Material : granite marble basalt iron ore cobble shale bluestone coal cobblestone construction waste Range of Application : Stone crushing in building materials industry highway and railway construction housing and other industries. DPC series single-stage impact hammer crusher is one of the leading products in our company, which is widely used to crush limestone, stones with medium hardness, compressive strength under 200 Mpa and calcium content higher than 40%. It can crush the big size ore to the small size ones which can be directly fed to the grinding mill, thus replace the traditional two-stage crushing, simplify the process, save infrastructure investment and production cost.

...more

Single Cylinder Hydraulic Cone Crusher

Details The electromotor leads the eccentric sleeve to rotate by the V-belt drive shaft and drive gear. Working principle The electromotor leads the eccentric sleeve to rotate by the V-belt drive shaft and drive gear. The movable cone does rotary and pendulum movement under the leading role of eccentric sleeve which makes the movable cone and fixed cone close and far away from time to time. The raw material is crushed in the crusher chamber by squeezing and striking continuously. The crushed stone discharges from the bottom. Product introduction Production capacity : 70-800T/H Notice: this capacity is mean value and the specific production capacity is subject to clients’ actual equipment configuration. Processable Material : granite marble basalt iron ore cobble shale bluestone coal cobblestone construction material Range of Application : metallurgy construction white fuel transportation chemical engineering construction material The single cylinder hydraulic cone crusher is applicable to mineral fine grinding and ultra fine grinding. This series of crushers are divided into PYB, PYZ, PYD, respectively used in coarse crushing, secondary crushing, and fine crushing. It is easy for crushing the material to the required size range, and meets the production needs of customers.

...more

Silica Sand Production Line

Details It is a full set of quartz sand production line equipment produced and designed by EMCC which provides you with the comprehensive technical support. Advantage 1. Reasonable inlet and outlet designimproves equipment production stability; 2. High manganese steel linerismore wear-resistant and with longer working life; 3. Theclosed cycle of productioncan ensure both fineness and production efficiency; 4. The equipment can independently complete the whole production process from raw material crushing equipment, transport, milling to the finished product collection, storage and packaging. 5. It canalso use special ball mill lining for special industryto get non-ferrous products. Product introduction Production capacity : 20-600T / H Note: this is only an average value and the specific value is subject to the clients’actual equipment configuration in site. Processable Material : For quartz & silica sand crushing or grinding process. Range of Application : Glass foundry ceramics and refractories smelting ferrosilicon metallurgical flux metallurgy construction chemicals plastics rubber abrasive industry and other industries. It is a full set of quartz sand production line equipment produced and designed by EMCC which provides you with the comprehensive technical support. This quartz sand production line is mainly composed of bucket elevator, jaw crusher, frequency screw feeder, MQX superfine ball mill, vortex classifier, cyclone powder collector and pulse dust collector. After ball mill processing, quartz sand powder can be widely used in glass, foundry, ceramics, refractories, smelting ferrosilicon, metallurgical flux, metallurgy, construction, chemicals, plastics, rubber, abrasive and other industries. Working principl After primary crushing by a small jaw crusher crushed materials enter hammer crusher for a second crushing and then being lifted into big hopper by bucket elevator through a frequency conversion screw feeder into the MQX superfine mill for fine grinding. The powder grinded will be transported by bucket elevator to the vortex grader for grading screening. Unqualified powder mill returns to ball mill and qualified powder is brought into the powder collector by updraft cyclone. Most of the qualified powder will be separated from air flow in the collectorand be collected. Trace amount of fine powder follows airflow into the pulse dust catcher. With this required fineness powder is gathered up and meanwhile air is purified by the dust catcher.

...more

Series Vertical Shaft Impact Crusher

Details VSI vertical shaft impact crusher (sand making machine) is our crystallization of diligence and wisdom . Advantage Two crushing ways of “rock on rock” and “rock on iron”. Multiple crushing ways meet the needs of different materials crushing. Dual Pump Design There is only one pump working in normal use. When the value of the pressure and flow rate do not reach the set value or when the first pump fails the second will open automatically to ensure the normal operation of the host. Bearing Bit Thermostat Bearing bit thermostat and pump automatic cycle ensure that the temperature inside the bearing cartridge similar to the oil in the tank to prevent the winter freeze. Hydraulic Arms Hydraulic arm design greatly reduces maintenance costs. Working principle VSI crusher design is based on the principle of mutual crushing and friction in the high-speed movement materials. This type sand making equipment can not only crush stones but also the stones and gravel can be shaped by it. According to feeding method centrifugal impact crusher working form is divided into central feeding and central with cascade feeding; the crush form is divided into “rock on rock” and “rock on iron” according to material compressive strength abradability. So the VSI crusher can be divided into four kinds: “rock on rock” and “rock on iron” with central feeding “rock on rock” and “rock on iron” with central with cascade feeding. Material from the hopper falls into VSI sand crusher and will be divided into two parts. One part passed into high speed rotating wheel to be accelerated and high-speed projectile rapidly impact crushing another part of the material from points around the tray and will be impacted on the vortex branch cavity lining together. Then it will be bounced back to the top of vortex chamberand the movement direction would be changed to start moving down on the diagonal; materials emitters from the impeller form a continuous material curtain. Finally crushed material discharge from the lower discharge port. Product introduction Production capacity : 60-500T / H Note: this is only an average value and the specific value is subject to the clients’ actual equipment configuration in site. Processable Material : Limestone river gravel rocks bluestone cobblestone weathered sand basalt granite quartz diabase etc. Range of Application : Non-metallic minerals building materials artificial sand and a variety of metallurgical slag crushing and shaping VSI vertical shaft impact crusher (sand making machine) is our crystallization of diligence and wisdom . Its integrated design we owe to the technology R&D specialists who personally go to the scene to understand the demand and opinions of equipment operators. By increasing production, reducing wear cost, prolonging maintenance cycle, thus we developed this multi-purpose crusher which has a couple ways of feeding and crushing modes, making it become the preferred device in the fields of stone integer, artificial sand, refractory, ball mill feeding, industrial construction materials processing and so on.

...more

Series Micropowder Grinder Production Line

Details This ultra-fine powder production line configuration meets customersreqirement for final product fineness between 325-1250 mesh. Advantage 1.Low investment and high efficiency.At the same fineness, HGM grinder is with lower power consumption, shorter recovery periodand 45% higher capacity than jet mill; 2.Wearing parts uses high-quality wear-resistant materials, expanding service life more than one year. And the final powder fineness can reach d97≤5um; 3.There is not rolling bearing orbolt inside the grinding chamber, avoiding equipment damage caused by bearing damage or bolts looseness. It adopts high-efficiency pulse dust collector that effectively reduces dust pollution and makes better dust removal. Product introduction Production capacity : 0.35-6T / H Note: this is an average value and the specific value is subject to the clients’actual equipment configuration in site. Processable Material : Powder grinding of limestone calcite fly ash calcium carbide desulfurization kaolin calcium carbonate coal gypsum slag powder bentonite barite marble talc refractories etc. Range of Application : Grinding processing of mineral materials in metallurgy building materials chemical mining etc. This ultra-fine powder production line configuration meets customers’reqirement for final product fineness between 325-1250 mesh. Working principle After primary crushing by a small jaw crusher materials enter hammer crusher for a second crushingand then bucket elevator lifts the crushed material into hopper; screw conveyor conveys material from hopper into the HGM three-ring medium speed mill for grinding. Under the action of wind in the mill grinded material through the spout above into cyclone powder collector. In the collector most of powder will be separated from airflow and be collected. Trace amount of fine powder follows airflow into the pulse dust catcher. With this required fineness powder is gathered up and meanwhile air is purified by the dust catcher.

...more

Series Micropowder Grinder

Details HGM Series of Three-rings and Medium-speed Micro-powder Grinder is absolute advanced leading machine in grinding mill industry. Advantage Long Service Life Service life could be 1 year. Service life is longer than wear-out part’s of impact crusher and turbine crusher if material and product size are same. High Efficiency and Low Consumption Under the condition of same material power and final product size its capacity is higher than jet mill and stirred mill by 40%. Superfine Powder Process Final size of the material processed by superfine mill could reach d97≤5μm. Safety Operating No antifriction bearing and bolt inside the grinding cavity no bearing or sealing element or bolt falling out and damaging machinery situation. Product introduction Processable Material : Limestone calcite fly ash calcium carbide kaolin calcium carbonate coal gangue gypsum slag ore slag coal dust bentonite barite marble talc refractory material. Production capacity : 0.35-6T/H Notice: Mean value the specific production capacity is subject to clients’ actual equipment configuration. Range of Application : Non flammable brittle material whose Moh’s hardness is less than 6. Working principle HGM Series of Three-rings and Medium-speed Micro-powder Grinder Mill is also called superfine grinding mill, it’s a new type superfine powder process grinder designed by EMCC and based on many years’ grinding mill production experience, this new type grinding mill absorbed advanced machinery manufacturing technology from Sweden and it was made after 20 times tests. HGM Series of Three-rings and Medium-speed Micro-powder Grinder is absolute advanced leading machine in grinding mill industry. HGM Series of Three-rings and Medium-speed Micro-powder Grinder is widely used in making fine powder or ultra-fine powder, and the raw materials should be non-inflammable and non-explosive under the Moh’s hardness less than 6 grade such as limestone, calcite, dolomite, kaolin, bentonite, talc, illite, pyrophillite, barite, meerschaum, fluorite, potash ore, etc. The lifetime of spare parts is relied on the hardness of raw materials, and is lowered once the Moh’s hardness is up to 4-6 grades.

...more

Series Hyper Pressure Grinder

Details Hyper Pressure V Type Grinder is new type high efficiency grinding mill designed by EMCC engineer combining clients requirement and practical situation. Advantage Star rack and V type grinding roller centrifugal force is transformed to grinding force grinding roller parallel transmit around vertical axis to press grinding ring to guarantee the max surface contact of grinding roller and grinding ring capacity is improved by 30%. Classifier is available According to fineness requirement bladed classifier (80-325 mesh) and cage classifier (200-1250 mesh) are available. Spacer protective measures Main machine is under protection easy to be replaced and maintenance costs is reduced Grinding device Grinding roller and grinding ring get wear uniformly and lengthen the using lifetime. Product introduction Production capacity : 0.5-40T/H Notice: this capacity is mean value capacity and the specific production capacity is subject to clients’ actual equipment configuration. Processable Material : Power process for limestone calcite fly ash calcium carbide kaolin calcium carbonate coal gangue gypsum slag ore slag coal dust bentonite barite marble talc refractory material. Range of Application : Glass rubber farm chemical enamel oil paint phosphatic fertilizer and papermaking industry. Hyper Pressure V Type Grinder is new type high efficiency grinding mill designed by EMCC engineer combining clients’ requirement and practical situation. Compared with traditional high pressure trapezium mill and high pressure overhang roll mill in the market, it has many advantages. Hyper Pressure V Type Grinder is widely applied in glass, rubber, farm chemical, enamel, oil paint, phosphatic fertilizer and papermaking industry and it could process material whose Moh’s hardness is less than 9.3, moisture is less than 6%, such as talc, barite, calcite, limestone, manganese ore, iron ore, quartz stone and bentonite. Working principle After reducing driving force of the main motor by the gear reducer when the drive center axis and the quincunx rack fixed on the center axis revolve under the centrifugal force the roller revolves around the center axis at the same time parallel swing around the shaft making the roller compress out side to the ring thus ensure that the roller and ring has maximum surface contact. At the same time the roller self revolves around the roller shaft making the material scooped up by the shovel blade to grind after grinding the powder blew to upper part of the mainframe then separating by the separator too coarse powder drops to the grinding room to re-grind the qualified powder airflows into the cyclone powder collector through the discharging pipe is qualified product.

...more

Scrubber

Details Gas gets into the scrubber tangentially through the bottom air intake, under the action of the fan, quickly filled the air intake segment space, and then flow evenly through uniform flow section up to the first stage feeding absorption section. Advantage Small resistance, low consumption, low noise, high purification efficiency, compact structure, small cover space, good corrosion resistance and aging resistance, light weight. Product introduction Production capacity : 300-1330mm Processable Material : Treatment of all kinds of harmful gases Gas gets into the scrubber tangentially through the bottom air intake, under the action of the fan, quickly filled the air intake segment space, and then flow evenly through uniform flow section up to the first stage feeding absorption section. On the surface of the filler, the pollutants in gas phase react with the liquid phase substance. The reaction resultant (mostly soluble salts) flowing into the lower portion of the reservoir with the absorption liquid. The gas not completely absorbed continues rises into the spray section. The absorption liquid sprays in high-speed through the uniformly distributed nozzle in the ejection segments, generating numerous small droplets continue react with the gas. This treatment can cool the exhaust gas to remove particles and other impurities. The tower uppermost segment is for defogging, and the absorbing liquid droplets carried by gas are cleared here. The treated clean air is blown into the atmosphere through the upper end of the scrubber. Working principle Gas gets into the scrubber tangentially through the bottom air intake, under the action of the fan, quickly filled the air intake segment space, and then flow evenly through uniform flow section up to the first stage feeding absorption section. On the surface of the filler, the pollutants in gas phase react with the liquid phase substance. The reaction resultant (mostly soluble salts) flowing into the lower portion of the reservoir with the absorption liquid. The gas not completely absorbed continues rises into the spray section. The absorption liquid sprays in high-speed through the uniformly distributed nozzle in the ejection segments, generating numerous small droplets continue react with the gas. This treatment can cool the exhaust gas to remove particles and other impurities. The tower uppermost segment is for defogging, and the absorbing liquid droplets carried by gas are cleared here. The treated clean air is blown into the atmosphere through the upper end of the scrubber. Technical Parameters Scrubber The Scrubber has A, B and C three models. A model is wet scrubber. B model is acid and alkaline gases scrubber. C model is organic gases and heat gases scrubber. A Series Scrubber Parameters

...more

Saya Office & Home Scissors, SY-SC08

Sand Washing Machine

Details XSD efficient bucket sand washing machine’s biggest characteristic is that the transmission part is separated from water and sand, so failure rate is much lower than other sand washer, and the novel sealing structure and reliable transmission could be well used to ensure the cleaning and dehydration effect. Advantage Rational Design of The Impeller Impeller design is reasonable with the characteristics of high cleaning degree reasonable structure large quantity and low consumption. Unique Transmission Gear Entire transmission (including bearings) is isolated from water and raw material to avoid bearing damage due to soaking sand and pollutants. High Quality Screen Using high quality screen made of wear-resistant materials effectively extending the service life of sand washer; and except the screen generally do not need to equip other wearing parts. High Quality Bearing Using the bearing products of brands ZWZ and SKF which are the largest bearing manufacturers in China. Working principle The electric motor runs slowly with the impellor after being decelerated by the belt decelerator and gears wheel. The sand and stone flow into washing launder from feeding launder roll with the impellor and grind each other. The impurity covering the sand is washed away. At the same time adding more water the strong water flow will take away waste and some low-weight wastes from washing launder. Through the above process the washing function is finished. The clean sand and stone is lifted up by vane. When it goes up slowly the water begins to drop through the mesh and fall back in the washing launder. On one hand water is removed from the sand and stone; on the other hand the water can be fully used. Finally the sand and stone go to the out launder from the rotary impellor to finish the washing task. Product introduction Production capacity : 20-150T / H Note: this is only an average value and the specific value is subject to the clients’ actual equipment configuration in site. Processable Material : XSD sand washing plant is suitable for nature sand and artificial sand crushed from limestone river gravel rocks bluestone cobblestone weathered sand basalt granite quartz diabase etc. Range of Application : Construction sites gravel plants concrete hydropower dam site metallurgy building materials and other operations for industries washing. XSD efficient bucket sand washing machine’s biggest characteristic is that the transmission part is separated from water and sand, so failure rate is much lower than other sand washer, and the novel sealing structure and reliable transmission could be well used to ensure the cleaning and dehydration effect. With features of reasonable structure, large capacity, low power consumption, etc., it is a deserved ideal industrial sand washing equipment. As this sand washer is very good for separating and cleaning stone powder and soil in the artificial sand, it is often associated with sand making machine for construction sand crushing and washing.

...moreBe first to Rate

Rate ThisOpening Hours