Sprayable Rubber Adhesive

NEOSOL Sprayable Adhesives are high-quality, versatile adhesives designed for various applications that require a strong, durable bond. These adhesives are formulated to be easily applied using spray equipment, ensuring a uniform and efficient coating for different surfaces. Key Features: High Bond Strength: Provides exceptional adhesion to a wide range of materials, including EPDM granules, rubber, foam, textiles, metals, and plastics. Ease of Application: Designed for spray application, ensuring a smooth, even distribution that enhances the bonding process and reduces waste. Quick Drying: Fast drying times help speed up the application process and minimize downtime, making it ideal for large-scale projects. Versatility: Suitable for various industrial, commercial, and residential applications, including flooring, insulation, automotive, and construction. Environmental Considerations: Formulated to be low in volatile organic compounds (VOCs), making it a safer choice for both installers and the environment. Durability: Resistant to weather, moisture, and temperature fluctuations, ensuring long-lasting performance in diverse conditions. Applications: Flooring Installations: Ideal for bonding materials in flooring projects, including sports surfaces, carpets, and vinyl tiles. Construction: Suitable for a variety of construction applications, such as insulation panels, roofing materials, and wall coverings. Automotive: Used in the automotive industry for bonding interior components, headliners, and insulation. Foam and Fabrication: Excellent for use in foam and textile bonding, providing a strong, flexible hold. Technical Specifications: Base: Typically a synthetic polymer or polyurethane formulation. Color: Available in various colors, commonly clear or light amber, to suit different application needs. Viscosity: Optimized for spray application, allowing for a consistent and even coat. Dry Time: Fast drying, typically within minutes, depending on environmental conditions and application thickness. Shelf Life: Generally, a shelf life of around 12 months when stored in optimal conditions (cool and dry). Benefits: Efficiency: Spray application reduces labor time and enhances coverage efficiency. Strong Bond: Ensures a reliable and robust bond for various materials, contributing to the longevity and durability of the bonded surfaces. Safe Application: Low VOC formulations make it safer to use in enclosed or poorly ventilated spaces. Weather Resistance: Maintains adhesive properties in different weather conditions, providing a durable bond in both indoor and outdoor applications. Summary: NEOSOL Sprayable Adhesives offer a robust, efficient, and versatile solution for a wide range of bonding applications. Their high bond strength, quick drying time, and ease of application make them ideal for industries that require reliable and durable adhesive solutions. Whether for flooring, construction, automotive, or other industrial uses, NEOSOL Sprayable Adhesives deliver consistent and long-lasting performance.

...more

Sanding Sealer

we Offer sanding Sealer Under the Brand Name of Neosol. the Neosol Sanding Sealer is An Ultimate Product to Be Used On Wood Surfaces to Protect the Change Due to Humidity. Our Sanding Sealer is Checked Under Stringent Quality Checks, Therefore Assuring Optimum Quality. We Provide the Sanding Sealer At Market Leading Prices for Our Clients. used For filling and Leveling Wood Surfaces Where Transparency is Required, Sealing Under Cellulose Lacquers On all Types of Wood, Finishing of Less Exposed Surfaces such as the Interior of Drawers, Cupboards Etc pack Sizes 20 Ltr, 4 Ltr, 1 Ltr and ½ Ltr

...more

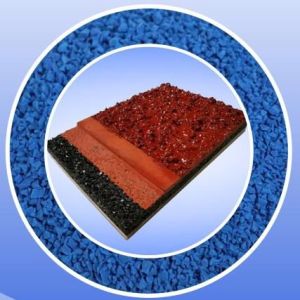

Rubber Granule Binders

Rubber granule binders are specialized adhesives used to bond rubber granules together, creating resilient and durable surfaces for various applications. These binders ensure a strong and flexible bond, ideal for constructing sports surfaces, playgrounds, and safety flooring. Key Features: Strong Adhesion: Provides excellent bonding strength, ensuring rubber granules are securely held together for a durable surface. Flexibility: Maintains flexibility, allowing the surface to absorb impacts and reduce stress on users' joints. Weather Resistance: Formulated to withstand various weather conditions, including UV exposure, moisture, and temperature fluctuations. Quick Curing: Fast curing times facilitate quicker installation and reduce downtime. Low VOC: Environmentally friendly with low volatile organic compound content, ensuring safety for installers and end-users. Applications: Sports Surfaces: Ideal for creating durable and high-performance running tracks, tennis courts, and other athletic surfaces. Playgrounds: Suitable for constructing safe and resilient playground surfaces, providing cushioning and injury reduction. Safety Flooring: Used in safety flooring for industrial and commercial areas where slip resistance and impact absorption are critical. Rubber Paving: Perfect for creating rubber-paved paths, walkways, and other decorative outdoor surfaces. Summary: Rubber granule binders are essential adhesives that provide strong, flexible, and weather-resistant bonds for rubber granule surfaces. These binders are crucial in constructing safe, durable, and high-performance surfaces for sports, playgrounds, safety flooring, and rubber paving, ensuring long-lasting performance and environmental safety.

Size : Etc

Application : For Mixing The Rubber Granule

...more

PU Neosol Binder

NEOSOL PU Binder is a high-performance polyurethane binder designed for use in creating synthetic sports surfaces, particularly running tracks. Here’s a detailed description of NEOSOL PU Binder: Product Overview: NEOSOL PU Binder is a versatile, high-quality, and durable polyurethane-based adhesive. It is specifically formulated to bond EPDM granules and other rubber particles, providing a resilient and long-lasting surface suitable for various athletic and recreational activities. Key Features: Exceptional Adhesion: Offers superior bonding capabilities, ensuring that the granules are securely held together, which enhances the longevity and durability of the sports surface. Elasticity and Flexibility: Maintains excellent flexibility and elasticity, allowing the surface to absorb impacts effectively, reducing stress on athletes' joints. Weather Resistance: Designed to withstand a wide range of weather conditions, including UV exposure, temperature fluctuations, and moisture, without degrading. Environmental Compatibility: Formulated to be environmentally friendly, with low VOC (Volatile Organic Compounds) content, making it a safer choice for installers and users. Easy Application: Can be easily mixed and applied, ensuring a smooth and even coating over the granules for consistent surface quality. Applications: Running Tracks: Ideal for creating all-weather running tracks that offer consistent performance and safety. Playgrounds: Suitable for use in playground surfaces where safety and durability are paramount. Sports Courts: Can be used for various sports courts, including tennis and basketball, where a durable and high-performance surface is required. Multi-Purpose Athletic Fields: Perfect for multi-use athletic fields, providing a versatile and resilient surface for various sports. Technical Specifications: Base: Polyurethane Color: Typically clear or slightly amber, allowing the color of the EPDM granules to show through. Viscosity: Medium to high viscosity for optimal application and bonding. Cure Time: Fast-curing properties to ensure quick installation and minimal downtime. Shelf Life: Generally, a shelf life of around 12 months when stored in optimal conditions (cool and dry). Benefits: Enhanced Safety: Provides a cushioned and non-slip surface, reducing the risk of injuries. Low Maintenance: Once cured, the surface requires minimal maintenance, making it cost-effective over its lifespan. Aesthetic Appeal: Helps in creating visually appealing surfaces with vibrant colors and consistent texture. NEOSOL PU Binder is the preferred choice for constructing high-performance and durable athletic surfaces, ensuring that athletes can train and compete on the best possible tracks.

Application : Laminating

Country of Origin : India

...more

bonding adhesive

We are engaged in providing Bonding Adhesive to our esteemed clients. WPF-506 is a two component PU resin based, seamless floor finish. It can be applied on a variety of surfaces to provide a good aesthetic appearance to the floor and walls besides being smooth & glossy, it is dust proof, hard wearing and resistant to mild acids and alkalis. It can also be used as a wall coating where chemical splashes, fumes, petrol spillage, alkalis, salts, solvents printing inks etc. occur. It facilitates easy maintenance of floors and walls and also extends their service life.

...more

NEOSOL PU BOND

PU BOND-2 is a 2-Component adhesive system which consists of two reactive components exactly matched with each other and which are kept and transported separate from each other. Their main feature is that they have high strength and, at the same time, they are flexible. After curing, the products present no health or ecological hazards.

...more

Non Flammable Adhesive

non-flammable adhesives are specialized bonding agents designed to minimize the risk of fire during application and use. they are formulated without volatile organic compounds (vocs) or with low levels of vocs, which are typically responsible for the flammability in many conventional adhesives. here are some key features and types of non-flammable adhesives: features of non-flammable adhesives safety: these adhesives significantly reduce the risk of fire and explosion, making them ideal for use in environments where flammable materials are a concern. low voc content: they contain minimal or no vocs, contributing to better indoor air quality and meeting strict environmental regulations. high bond strength: despite being non-flammable, these adhesives often provide strong bonding capabilities suitable for various materials. durability: they are designed to withstand different environmental conditions, such as temperature changes, moisture, and chemical exposure. ease of use: many non-flammable adhesives come in user-friendly formulations, including water-based or latex-based options, making them easy to apply and clean up. types of non-flammable adhesives water-based adhesives: these adhesives use water as the primary solvent, making them non-flammable. they are commonly used in woodworking, paper bonding, and textile applications. latex-based adhesives: derived from natural or synthetic rubber, latex-based adhesives are non-flammable and provide flexible, strong bonds. they are often used in carpet installation, shoe manufacturing, and upholstery. acrylic adhesives: acrylic adhesives can be formulated to be non-flammable. they are known for their strong bonding properties and resistance to environmental factors, suitable for construction and automotive applications. epoxy adhesives: some epoxy formulations are non-flammable, especially those designed for industrial use. these adhesives are highly durable and suitable for bonding metals, plastics, and composites. silicone adhesives: non-flammable silicone adhesives are ideal for sealing and bonding applications that require high-temperature resistance and flexibility, such as in electronics and automotive industries. polyurethane adhesives: certain polyurethane adhesives are non-flammable and provide strong, durable bonds for wood, metal, and plastic. they are often used in construction and manufacturing. applications of non-flammable adhesives construction: safe for use in building interiors, reducing fire hazards during installation. automotive: used in car interiors and components where safety standards are critical. electronics: suitable for bonding components where heat generation could be a concern. aerospace: non-flammable adhesives are vital for safety in aircraft construction and repair. consumer goods: ideal for products like shoes, textiles, and furniture, where both safety and performance are important. advantages enhanced safety: reduces the risk of fire-related accidents. environmental compliance: meets stringent environmental and safety regulations. versatility: suitable for a wide range of materials and applications. improved air quality: low or no voc emissions contribute to healthier indoor environments. overall, non-flammable adhesives are an essential component in industries where safety, performance, and environmental considerations are paramount.

Color : Transparent

Form : Gel

Type : Adhesives

Country of Origin : India

...more

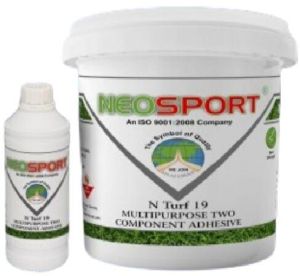

Neosport N-Turf 19 Adhesives

(Multipurpose Two-Component Artificial Grass Adhesives) N TURF 19 is a high-performance, two-component adhesive specifically designed for the installation of artificial grass and synthetic turf. This adhesive ensures a strong, durable bond between the turf and the substrate, providing excellent performance in various environmental conditions. Key Features: Two-Component System: Comprises a resin and a hardener that, when mixed, form a robust adhesive bond suitable for demanding applications. High Bond Strength: Offers superior adhesion to artificial grass backing and a variety of substrates, including concrete, asphalt, and compacted aggregate bases. Weather Resistance: Formulated to withstand extreme weather conditions, including UV exposure, rain, and temperature variations, without compromising the bond. Versatility: Suitable for a wide range of applications, including sports fields, landscaping, playgrounds, and recreational areas. Long Working Time: Provides adequate working time for precise placement and adjustment of turf, ensuring a professional finish. Environmental Safety: Low in volatile organic compounds (VOCs), making it a safer option for installers and environmentally friendly. Applications: Sports Fields: Ideal for securing synthetic turf in football, soccer, and multi-sport fields, providing a stable and reliable surface for athletic activities. Landscaping: Perfect for residential and commercial landscaping projects where artificial grass is used to enhance aesthetic appeal and functionality. Playgrounds: Suitable for playground installations, ensuring a safe and durable surface for children’s play areas. Recreational Areas: Used in various recreational and leisure areas to create low-maintenance, visually appealing, and long-lasting synthetic turf surfaces. Technical Specifications: Components: Resin (Part A) and Hardener (Part B). Mix Ratio: Typically mixed at a specific ratio as recommended by the manufacturer to ensure optimal performance. Color: Usually available in a green or clear color to blend seamlessly with artificial grass. Viscosity: Medium viscosity for easy mixing and application. Working Time: Provides sufficient working time after mixing to allow for precise installation. Cure Time: Fast curing, with initial set time within a few hours and full cure achieved in 24-48 hours, depending on temperature and humidity. Benefits: Durable Bond: Ensures a long-lasting and stable bond, maintaining the integrity of the synthetic turf installation over time. Easy Application: Simple mixing and application process, suitable for professional installers and DIY projects alike. Enhanced Aesthetic: Seamlessly integrates with artificial grass, providing an invisible bond that enhances the overall appearance. Cost-Effective: Reduces the need for frequent maintenance and replacement, offering cost savings over the lifespan of the installation. Safe and Eco-Friendly: Low VOC content promotes a healthier environment for installers and end-users. Summary: N TURF 19 Multipurpose Two-Component Artificial Grass Adhesive is an ideal choice for securing synthetic turf in a variety of settings. Its robust bonding capabilities, resistance to weather conditions, and ease of application make it a preferred solution for creating durable and aesthetically pleasing artificial grass surfaces. Whether used in sports fields, landscaping, playgrounds, or recreational areas, N TURF 19 ensures reliable performance and long-term durability.

Color : Green

Application : Plastic Sealing,Artificial

Type : Plastic Adhesives

Country of Origin : India

...more

NEOSPORT N-Track 91

2 Component Sealant Coating for Running Track Systems & Sealing Layers Description- Overview N-Track 91 is an advanced, two-component sealant coating system specifically formulated for the sealing and finishing of running track surfaces. This system provides exceptional durability, flexibility, and weather resistance, ensuring a high-performance and long-lasting track surface. It is ideal for use in professional sports facilities, schools, and recreational areas. Key Features 1. Durability: o Wear Resistance: Engineered to withstand heavy foot traffic and the rigors of athletic activities, ensuring longevity. o Weather Resistance: Offers excellent protection against UV radiation, rain, and extreme temperature variations. 2. Safety: o Slip Resistance: Provides a non-slip surface to reduce the risk of injuries for athletes. o Impact Absorption: Designed to absorb impact, minimizing stress on athletes' joints and muscles. 3. Performance: o Seamless Surface: Creates a smooth, consistent surface that enhances athletic performance. o Excellent Traction: Delivers superior grip, improving safety and performance during athletic activities. 4. Aesthetic Appeal: o Color Stability: Available in various colors with UV stable pigments that prevent fading and discoloration over time. o High-Quality Finish: Provides a visually appealing finish that enhances the look of the track. 5. Environmental Resistance: o Waterproofing: Forms a waterproof barrier that protects the underlying layers from moisture damage. o Chemical Resistance: Resistant to common chemicals and substances, ensuring a long-lasting surface with minimal maintenance. System Composition 1. Component A: o A polyol blend that serves as the reactive base of the coating system. 2. Component B: o An isocyanate that reacts with Component A to form a robust polyurethane sealant coating. Application Process 1. Surface Preparation: o Cleaning: Ensure the surface is clean, dry, and free from dust, dirt, oil, and other contaminants. o Priming: Apply a primer if necessary, to enhance adhesion between the existing surface and the sealant coating. 2. Mixing: o Component Mixing: Mix Components A and B according to the manufacturer’s instructions. Ensure thorough mixing to achieve a consistent and reactive blend. 3. Application: o Application Method: Use suitable tools such as rollers, squeegees, or spray equipment to apply the mixed coating. Ensure even and consistent application to achieve the desired thickness. o Layering: Multiple layers may be applied to build up the required thickness and performance properties. 4. Curing: o Setting Time: Allow the coating to cure according to the specified curing time. Avoid traffic or movement on the track during this period. o Final Inspection: After curing, inspect the surface to ensure complete and even coverage, making any necessary touch-ups. Benefits Long-Lasting Performance: Provides a durable and resilient surface that can withstand intense use and various environmental conditions. Low Maintenance: High resistance to wear, weather, and chemicals reduces the need for frequent repairs and maintenance. Enhanced Safety: Offers a safe, non-slip surface that reduces the risk of injuries and enhances athlete performance. Aesthetic Quality: Maintains its appearance and functionality over time, contributing to the overall appeal of the track facility. Technical Specifications Mixing Ratio: Specified by manufacturer (typically 1:1 or as recommended). Pot Life: Adequate working time for application (varies based on environmental conditions). Curing Time: Typically ranges from several hours to a day, depending on temperature and humidity. Application Temperature: Recommended temperature range for optimal performance.

...more

NEOSPORT N-Track 64

2 Component Spray Coat Systems for Running Tracks Description- Overview N-Track 64 is an advanced, two-component spray coating system designed specifically for the construction and maintenance of running tracks. This system provides a seamless, durable, and high-performance surface that meets the rigorous demands of athletic activities. It is ideal for professional sports facilities, schools, and recreational areas. Key Features 1. Durability: o Wear Resistance: Formulated to withstand heavy foot traffic and athletic activities, ensuring a long-lasting surface. o Weather Resistance: Excellent resistance to various weather conditions, including UV radiation, rain, and temperature fluctuations. 2. Safety: o Slip Resistance: Provides a non-slip surface, reducing the risk of injuries for athletes. o Impact Absorption: Designed to absorb impact, minimizing stress on athletes' joints and muscles. 3. Performance: o Consistent Surface: Ensures a smooth and consistent running surface for optimal athletic performance. o Excellent Traction: Offers superior grip, enhancing athletes' performance and reducing the likelihood of slips. 4. Aesthetic Appeal: o Color Options: Available in various colors, allowing for customization to match team or facility colors. o Finish Quality: Delivers a high-quality finish that enhances the visual appeal of the track. 5. Environmental Resistance: o Waterproofing: The spray coating provides excellent waterproofing, protecting the underlying surface from moisture damage. o Chemical Resistance: Resistant to common chemicals and substances, ensuring longevity and low maintenance. System Composition 1. Component A: o Typically a polyol blend that acts as the reactive base of the coating system. 2. Component B: o Generally an isocyanate that reacts with Component A to form a durable polyurethane coating. Application Process 1. Surface Preparation: o Cleaning: Ensure the existing surface is clean, dry, and free from dust, dirt, oil, and other contaminants. o Priming: Apply a primer if necessary, to enhance adhesion between the existing surface and the new coating. 2. Mixing: o Component Mixing: Mix the two components (A and B) according to the manufacturer’s instructions, ensuring thorough mixing for a consistent and reactive blend. 3. Application: o Spray Application: Use a specialized spray equipment to apply the mixed coating onto the track surface. Ensure even and consistent application to achieve the desired thickness. o Layering: Multiple layers may be applied to achieve the required surface properties and thickness. 4. Curing: o Setting Time: Allow the coating to set and cure according to the specified curing time. Avoid any traffic or movement on the track during this period. o Final Inspection: After curing, inspect the track surface to ensure complete and even coverage, making any necessary touch-ups. Benefits Longevity: The durable formulation provides a long-lasting surface that can withstand intense use and various environmental conditions. Low Maintenance: The high resistance to wear, weather, and chemicals means less frequent repairs and maintenance. Enhanced Performance: Offers a safe and consistent surface that helps athletes perform at their best. Aesthetic Quality: Maintains its appearance and functionality over time, enhancing the overall look of the track facility. Technical Specifications Mixing Ratio: Specified by manufacturer (typically 1:1 or as recommended). Pot Life: Adequate working time for application (varies based on environmental conditions). Curing Time: Typically ranges from several hours to a day, depending on temperature and humidity. Application Temperature: Recommended temperature range for optimal performance.

...more

NEOSPORT N-Track 37

The N-Track-37 system is an advanced, high-performance solution designed to provide optimal surfaces for running tracks. This system combines the benefits of a coating and sealant sandwich to create a durable, safe, and resilient track surface that meets the demands of athletes and sports facilities. Key Features 1. Durability: o Wear Resistance: The system is engineered to withstand heavy use and harsh weather conditions, ensuring a long lifespan for the track. o UV Stability: Resistant to UV radiation, preventing degradation and color fading over time. 2. Safety: o Slip Resistance: Provides a non-slip surface, reducing the risk of injuries. o Impact Absorption: Designed to absorb impact, minimizing stress on athletes' joints and muscles. 3. Performance: o Consistent Surface: Ensures a smooth and consistent running surface for optimal athletic performance. o Excellent Traction: Offers superior grip, enhancing athletes' performance and reducing the likelihood of slips. 4. Aesthetic Appeal: o Color Options: Available in various colors, allowing for customization to match team or facility colors. o Finish Quality: Delivers a high-quality finish that enhances the visual appeal of the track. 5. Environmental Resistance: o Waterproofing: The sealant layer provides excellent waterproofing, protecting the underlying surface from moisture damage. o Chemical Resistance: Resistant to common chemicals and substances, ensuring longevity and low maintenance. System Composition 1. Base Layer: o Comprised of a stable, resilient base that provides the foundational support for the track. Often made from recycled rubber materials to enhance shock absorption and sustainability. 2. Intermediate Coating Layer: o A specialized coating that enhances adhesion between the base and top layers. This layer ensures that the surface remains intact and prevents delamination. 3. Top Sealant Layer: o A high-performance sealant that provides the final surface. This layer is designed to be wear-resistant, UV stable, and waterproof, ensuring that the track remains in optimal condition. Installation Process 1. Surface Preparation: o The existing surface is cleaned and prepped to ensure proper adhesion of the N-Track-37 system. 2. Base Layer Application: o The base layer is applied and leveled to create a stable foundation. 3. Intermediate Coating Application: o The intermediate coating is applied to ensure strong adhesion between layers. 4. Top Sealant Layer Application: o The top sealant layer is applied, providing the final durable and attractive surface. 5. Curing and Finishing: o The system is allowed to cure properly before final inspections and markings are added. Benefits Longevity: The combination of coating and sealant provides enhanced durability and a longer lifespan compared to traditional track surfaces. Low Maintenance: The high resistance to wear, weather, and chemicals means less frequent repairs and maintenance. Athlete Performance: Provides a safe and consistent surface that helps athletes perform at their best. Environmental Sustainability: Utilizes recycled materials and provides long-term environmental benefits through reduced maintenance needs. N-

Application : Industrial

Country of Origin : Made in India

...more

Neosol Binder

NEOSOL Binder is a high-quality adhesive specifically formulated for bonding EPDM granules and other rubber particles in the construction of synthetic sports surfaces and playgrounds. This versatile binder ensures a durable, resilient, and weather-resistant surface, ideal for various applications. Key Features: Superior Adhesion: Provides excellent bonding strength, securely binding granules and particles to create a cohesive surface. Flexibility and Elasticity: Maintains flexibility, allowing the surface to absorb impacts and reduce stress on users' joints. Weather Resistance: Formulated to withstand harsh weather conditions, including UV exposure, moisture, and temperature variations. Fast Curing: Quick curing properties facilitate faster installation and minimal downtime. Low VOC: Environmentally friendly formulation with low volatile organic compound content, ensuring safety for installers and users. Applications: Running Tracks: Ideal for creating all-weather running tracks that offer consistent performance and safety. Playgrounds: Suitable for constructing durable and safe playground surfaces. Sports Courts: Perfect for various sports courts, including tennis and basketball, requiring high-performance surfaces. Multi-Purpose Athletic Fields: Used in multi-use fields, providing a versatile and resilient surface for different sports activities. Summary: NEOSOL Binder is a robust and versatile adhesive designed to create durable and high-performance synthetic sports surfaces. Its superior adhesion, flexibility, weather resistance, and fast curing make it an ideal choice for applications like running tracks, playgrounds, sports courts, and multi-purpose athletic fields.

Color : White

Feature : Heat Resistant

...more

Neosol AA - 700 rubber adhesives

AA-700 rubber adhesives are a type of specialized bonding agent designed to provide strong adhesion for rubber materials. These adhesives are typically used in applications where durability, flexibility, and resistance to environmental factors are crucial. Here is a detailed description of AA-700 rubber adhesives: Key Features of AA-700 Rubber Adhesives High Bond Strength: AA-700 adhesives offer excellent adhesion to various types of rubber, ensuring a strong and durable bond that withstands stress and mechanical forces. Flexibility: These adhesives maintain their flexibility after curing, allowing bonded materials to flex and bend without compromising the integrity of the bond. This is particularly important for applications involving dynamic loads or movements. Environmental Resistance: AA-700 rubber adhesives are formulated to resist environmental factors such as moisture, temperature extremes, chemicals, and UV exposure. This makes them suitable for both indoor and outdoor applications. Non-Flammable: They are designed to be non-flammable, reducing the risk of fire during application and use. This enhances safety in environments where flammable materials could pose a hazard. Easy Application: AA-700 adhesives can be applied easily using standard methods such as brushing, rolling, or spraying. They provide good workability and can be tailored to specific application requirements. Typical Applications Automotive: Used in the assembly of automotive parts, such as bonding rubber seals, gaskets, and trim components. Industrial: Suitable for bonding rubber components in machinery, equipment, and conveyor systems. Construction: Used for sealing and bonding rubber materials in building projects, such as roofing membranes and flooring installations. Footwear: Ideal for bonding rubber soles and other components in the manufacture of shoes and boots. Electronics: Employed in the assembly of electronic devices where rubber parts need to be securely bonded. Advantages Durability: Provides long-lasting bonds that can endure harsh conditions and repeated stress. Versatility: Can be used with a wide range of rubber types, including natural rubber, neoprene, EPDM, and more. Safety: Non-flammable properties make it safer to use in various environments, reducing fire hazards. Performance: Maintains adhesive properties under varying temperatures and environmental conditions, ensuring reliable performance. Application Guidelines Surface Preparation: Ensure that surfaces to be bonded are clean, dry, and free from contaminants such as oil, dust, and grease. Proper surface preparation is crucial for optimal adhesion. Application Method: Apply the adhesive evenly using a brush, roller, or spray equipment. Follow the manufacturer’s instructions for the specific application method and drying times. Curing: Allow sufficient curing time as recommended by the manufacturer. Curing times may vary depending on the adhesive formulation and environmental conditions. Safety Precautions: Use appropriate personal protective equipment (PPE) such as gloves and safety glasses when handling adhesives. Ensure adequate ventilation in the application area. Environmental and Safety Compliance AA-700 rubber adhesives are designed to meet environmental and safety standards, ensuring minimal impact on indoor air quality and overall safety during use. Always refer to the product’s Safety Data Sheet (SDS) for detailed information on handling, storage, and disposal. In summary, AA-700 rubber adhesives are a reliable choice for applications requiring strong, flexible, and durable bonds with rubber materials. Their non-flammable nature and resistance to environmental factors make them suitable for a wide range of industries and uses.

...more

Neosol Aa - (700) Synthetic Rubber Based Adhesive

Neosol Aa – 700 is a Synthetic Rubber Based Adhesive in Solvent Solution with Over 18 % - 20 Solid Content. It is Light Brown in Color and is Most Suitable for Foam to Foam, Rexine with Foam, Foam with Coir & Spring, Dg Canopy, Sports Goods, Footwear and Many other Applications. pack Sizes 20 Ltr, 5 Ltr, 1 Ltr, ½ Ltr & 200 Ml. Please Contact Us.

...more

Neosol AA - 500 synthetic rubber adhesives

Neosol AA 500 synthetic rubber adhesives are high-performance adhesives specifically designed for bonding synthetic rubber materials. These adhesives are known for their exceptional adhesion properties, durability, and versatility, making them suitable for a wide range of industrial and commercial applications. Key Features of Neosol AA 500 Synthetic Rubber Adhesives Strong Adhesion: Neosol AA 500 adhesives offer excellent adhesion to a variety of synthetic rubber substrates, ensuring a secure and durable bond. Flexibility: These adhesives maintain flexibility after curing, allowing the bonded materials to move and flex without compromising the bond strength. Environmental Resistance: Formulated to withstand harsh environmental conditions, Neosol AA 500 adhesives are resistant to moisture, chemicals, temperature variations, and UV exposure. Non-Flammable: Designed to be non-flammable, these adhesives enhance safety during application and use, reducing the risk of fire hazards. Easy Application: Neosol AA 500 adhesives can be applied using standard methods such as brushing, rolling, or spraying, providing ease of use and versatility. Typical Applications Automotive Industry: Ideal for bonding synthetic rubber components such as seals, gaskets, weather stripping, and trim parts. Industrial Applications: Suitable for use in machinery, equipment, and conveyor systems where synthetic rubber parts need to be securely bonded. Construction: Used for sealing and bonding synthetic rubber materials in building projects, including roofing membranes, flooring installations, and insulation. Footwear Manufacturing: Commonly used in the production of shoes and boots, particularly for bonding synthetic rubber soles and other components. Electronics: Employed in the assembly of electronic devices where synthetic rubber parts need to be securely bonded. Advantages Durability: Provides long-lasting bonds that can withstand harsh conditions and repeated mechanical stresses. Versatility: Compatible with a wide range of synthetic rubber types, including neoprene, EPDM, and nitrile rubber. Safety: Non-flammable properties make it safer to use in various environments, reducing potential fire hazards. Performance: Maintains adhesive strength and flexibility under varying temperatures and environmental conditions, ensuring reliable performance. Application Guidelines Surface Preparation: Ensure that the surfaces to be bonded are clean, dry, and free from contaminants such as oil, dust, and grease. Proper surface preparation is crucial for optimal adhesion. Application Method: Apply the adhesive evenly using a brush, roller, or spray equipment. Follow the manufacturer’s instructions for specific application methods and drying times. Curing: Allow sufficient curing time as recommended by the manufacturer. Curing times may vary depending on the adhesive formulation and environmental conditions. Safety Precautions: Use appropriate personal protective equipment (PPE) such as gloves and safety glasses when handling adhesives. Ensure adequate ventilation in the application area. Environmental and Safety Compliance Neosol AA 500 synthetic rubber adhesives are formulated to meet stringent environmental and safety standards, ensuring minimal impact on indoor air quality and overall safety during use. Always refer to the product’s Safety Data Sheet (SDS) for detailed information on handling, storage, and disposal. Conclusion Neosol AA 500 synthetic rubber adhesives are an excellent choice for applications requiring strong, flexible, and durable bonds with synthetic rubber materials. Their non-flammable nature and resistance to environmental factors make them suitable for a wide range of industries and uses, including automotive, industrial, construction, footwear manufacturing, and electronics.

...more

Neosol Aa - (500) Synthetic Rubber Based Adhesive

We Offer Neosol Aa – 500 is a Synthetic Rubber Based Adhesive in Solvent Solution with Over 17 - 19 % Solid Content. It is Light Yellow in Color and is Most Suitable for Various Insulation Substrates like Nitrile Rubber, Xpe Foam, Glass Wool to Aluminium, Carpet Laying, Vinyl Flooring and Many other Applications. pack Sizes 20 Ltr, 5 Ltr, 1 Ltr, ½ Ltr and 200 Ml. Please Contact Us.

...more

Leather Bonding Adhesive

We are engaged in providing Leather Bonding Adhesive to our esteemed clients. The Leather Bonding Adhesive is provided under the brand name of Jyoti™” Brand Kacha. The Leather Bonding Adhesive is made from Natural Rubber and is highly appreciated in the international market. We provide the Leather Bonding Adhesive at the market leading prices. Used For Bonding leather accessories and shoe components where temporary adhesion is required Pack Sizes 11 Kg Tin and 20 Ltr

...more

Latex Based Adhesive

we Offer latex Based Adhesive Under the Brand of Surya. the Latex Based Adhesive is a Natural Product Made of Latex, Which is Sourced, Directly from Kottayam in Kerala. It is An Environment Friendly Product Free of Industrial Solvents like Toluene / Benzene Etc. It is Suitable for Bonding Surfaces Where Less Bonding is Required. used In footwearautomotiveleather Industry pack Sizes 25 Ltr, 20 Ltr, and 5 Ltr

...more

Griptite AA - 400 synthetic rubber adhesives

Griptite AA-400 synthetic rubber adhesives are high-performance adhesives specifically formulated for bonding synthetic rubber materials. They are known for their excellent adhesive properties, durability, and resistance to environmental factors. Here’s a detailed description of Griptite AA-400 synthetic rubber adhesives: Key Features of Griptite AA-400 Synthetic Rubber Adhesives Strong Adhesion: Griptite AA-400 adhesives provide robust adhesion to a wide range of synthetic rubber materials, ensuring a reliable and durable bond. Flexibility: These adhesives maintain flexibility after curing, which is essential for applications where bonded materials are subject to movement and dynamic stresses. Environmental Resistance: The formulation of Griptite AA-400 adhesives includes properties that resist moisture, chemicals, temperature fluctuations, and UV exposure, making them suitable for both indoor and outdoor applications. Non-Flammable: Designed to be non-flammable, Griptite AA-400 adhesives enhance safety during application and use, reducing the risk of fire hazards. Easy Application: They can be applied using various methods such as brushing, rolling, or spraying, and they offer good workability and versatility in different application processes. Typical Applications Automotive Industry: Used in the assembly and repair of automotive parts, including bonding synthetic rubber seals, gaskets, weatherstripping, and trim components. Industrial Applications: Ideal for bonding synthetic rubber components in machinery, equipment, and conveyor systems. Construction: Suitable for sealing and bonding synthetic rubber materials in construction projects, such as roofing membranes, insulation, and flooring installations. Footwear Manufacturing: Commonly used in the production of shoes and boots, particularly for bonding synthetic rubber soles and other components. Electronics: Employed in the assembly of electronic devices where synthetic rubber parts need to be securely bonded. Advantages Durability: Provides long-lasting bonds that can endure harsh environmental conditions and repeated mechanical stresses. Versatility: Compatible with a wide range of synthetic rubber types, including neoprene, EPDM, and nitrile rubber. Safety: Non-flammable properties make it safer to use in various environments, reducing potential fire hazards. Performance: Maintains adhesive strength and flexibility under varying temperatures and environmental conditions, ensuring reliable performance. Application Guidelines Surface Preparation: Ensure that the surfaces to be bonded are clean, dry, and free from contaminants such as oil, dust, and grease. Proper surface preparation is crucial for optimal adhesion. Application Method: Apply the adhesive evenly using a brush, roller, or spray equipment. Follow the manufacturer’s instructions for specific application methods and drying times. Curing: Allow sufficient curing time as recommended by the manufacturer. Curing times may vary depending on the adhesive formulation and environmental conditions. Safety Precautions: Use appropriate personal protective equipment (PPE) such as gloves and safety glasses when handling adhesives. Ensure adequate ventilation in the application area. Environmental and Safety Compliance Griptite AA-400 synthetic rubber adhesives are formulated to meet stringent environmental and safety standards, ensuring minimal impact on indoor air quality and overall safety during use. Always refer to the product’s Safety Data Sheet (SDS) for detailed information on handling, storage, and disposal. Conclusion Griptite AA-400 synthetic rubber adhesives are an excellent choice for applications requiring strong, flexible, and durable bonds with synthetic rubber materials. Their non-flammable nature and resistance to environmental factors make them suitable for a wide range of industries and uses, including automotive, industrial, construction, footwear manufacturing, and electronics.

...more

Griptite Aa -( 400) Synthetic Rubber Based Adhesive

We Offer Synthetic Rubber Based Adhesive Which is Yellow in Color with Over 13 % Solid Content. It is the Most Suitable for Foam to Foam, Coir to Foam, Spring to Foam, Leather Soles to Uppers, Inner Fabric for Luggage and Electronic Items. pack Sizes 25 Ltr, 20 Ltr, 5 Ltr, 1 Ltr, ½ Ltr and 200 Ml. Please Contact Us.

...more

Football Kit Set

10 Piece (MOQ)

Color : Multicolor

Sleeve Type : Half Sleeves

Size : L, M, S

Gender : Female, Male

Feature : Easily Washable, Impeccable Finish

Pattern : Printed

Season : Summer, Winter

Country of Origin : India

...more

Clear Nitrocellulose Lacquer

We Offer Clear Nitrocellulose Lacquer Under the Brand Name of Neosol. the Neosol Nc Clear Lacquer is a High Quality Nitro Cellulose Based Quick Drying Clear Lacquer. It is a Clear or Colored Varnish that Dries By Solvent Evaporation. Clear Nitrocellulose Lacquer Needs to Be Applied Before Application of the Finish. used To give Woodworking Projects a Tough, Durable and Water-resistant Clear Finish pack Sizes 20 Ltr, 4 Ltr, 1 Ltr and ½ Ltr

...more

Neosol Brushable AA - 900

NEOSOL Brushable AA-900 is a high-performance, brushable adhesive designed for versatile bonding applications across various industries. This adhesive offers exceptional bonding strength, ease of application, and durability, making it suitable for numerous substrates and demanding environments. Key Features: High Bond Strength: Provides robust adhesion, ensuring reliable and strong bonds between various materials. Brushable Application: Formulated for easy application with a brush, allowing for precise and even coverage. Versatility: Suitable for bonding a wide range of substrates, including metals, plastics, rubber, wood, and composites. Durability: Resistant to environmental factors such as moisture, temperature fluctuations, and UV exposure, ensuring long-lasting performance. Fast Setting: Quick setting time to enhance productivity and reduce assembly time. Applications: Industrial Assembly: Ideal for general industrial bonding tasks requiring strong and durable adhesion. Automotive: Suitable for various automotive applications, including bonding interior and exterior components. Construction: Used in construction for bonding materials in projects that demand strong and reliable adhesion. Repair and Maintenance: Perfect for repair and maintenance tasks where a brushable adhesive is needed for precise application. DIY Projects: Suitable for a variety of do-it-yourself projects requiring a durable and easy-to-apply adhesive. Summary: NEOSOL Brushable AA-900 is a versatile, high-strength adhesive designed for brush application. Its exceptional bonding capabilities, ease of use, and durability make it ideal for a wide range of industrial, automotive, construction, repair, and DIY applications. With quick setting times and resistance to environmental factors, NEOSOL Brushable AA-900 ensures reliable and long-lasting bonds for various materials.

...more

Binders for Rebonded Foam

Binders for rebounded foam are specialized adhesives used to bond shredded or ground foam pieces together to form rebounded foam products. These binders ensure that the foam particles are securely adhered, creating a durable, resilient, and cohesive material ideal for various applications. Key Features: High Bond Strength: Provides robust adhesion, ensuring the foam particles are tightly bound together for maximum durability. Flexibility: Maintains flexibility and resilience of the foam, allowing the finished product to withstand compressive forces and repeated use. Fast Curing: Offers quick curing times to speed up the manufacturing process and increase production efficiency. Durability: Resistant to wear and tear, temperature fluctuations, and moisture, ensuring long-lasting performance of the rebounded foam. Low VOC: Formulated to be low in volatile organic compounds (VOCs), making it safer for workers and environmentally friendly. Applications: Carpet Padding: Ideal for producing rebounded foam underlays for carpets, providing cushioning and noise reduction. Furniture: Used in the manufacturing of rebounded foam cushions for furniture, offering comfort and support. Athletic Mats: Suitable for creating durable and resilient mats for gyms and sports facilities. Packaging: Used in protective packaging solutions where shock absorption is critical. Summary: Binders for rebounded foam are essential adhesives that provide strong, durable, and flexible bonds for rebounded foam products. With features like high bond strength, fast curing, and low VOC content, these binders are crucial for producing high-quality, resilient foam products used in various industries including flooring, furniture, sports, and packaging.

Material : Polyuerthane

Application : Construction,Packing,Transportation,Woodworking

Size : Etc.

Classification : Other Adhesives

...moreOpening Hours