Rubber Conveyor Belts

Get Price Quote

We at CCPL offers premium quality Rubber Conveyor Belts, which are used for various industrial purposes. “CCPL-INSTACON” make Conveyor Belts are made from Hi-grade Raw materials that ensure high tensile strength, resistivity to adverse conditions, good trough-ability and flexibility. These Conveyor Belts are suitable for all kind of Critical & Super-Critical Applications which can be customized as per customer requirement & application.

Rubber Conveyor Belts

Get Price Quote

We Deal in Rubber Conveyor Belts of Premium Quality Which are Used Frequently for Various Industrial Purposes. These are Made from Hi-grade Materials that Ensure High Durability, Tensile Strength, Resistivity to Adverse Conditions, Good Trough-ability and Flexibility. Industrial Conveyor Belts are Suitable for Most of the Application. the Conveyor Belts, We Deal In, are Reliable to the Greatest Extent Due to the Fact that These have a Wide Capacity Range and Very Much Customizable. Moreover, We are Counted among the Major Abrasion Resistant Rubber Conveyor Belt Manufacturers. designed to Handle the Toughest Conveying Applications, Ccpl's Conveyor Belt Series Fulfils the Highest National and International Standards for Tensile Strength and Wear Resistance. routinely Quality Tested in Our In-house Belt Testing Lab, all Ccpl Conveyor Belts are Covered By a 12 Month Manufacturer's Warranty. as An Approved Supplier to Many World Class Customers, You are Assured of the Highest Quality Products and Service. We Monitor all Stages of Our Entire Process with Uncompromising Quality Assurance, from Inquiry Right Through to Delivery-in Accordance with the Stringent Iso 9001 Guidelines. our Ep Multiply Fabric Rubber Conveyor Belts are Designed to Operate in a Wide Range of Industries, for Transporting Abrasive Materials such as Cement, Coal, Granite, Gravel Recycled Material, Iron Ore Grain, Beets, Potatoes, Timber in a Range of Temperatures from -30 C to 90 C (-22 F to 392 F). we Hold Large Stocks of Flat and Chevron Multiply Fabric Carcass Conveyor Belts from 2 Ply to 6 Ply in Various Widths Up to 2400mm (8 Ft), Tensile Strengths and Covers from Heavy Duty Primary to Light Duty Applications, Giving Excellent Cut, Impact and Wear Resistance.

Best Deals from Belt Conveyors

Rubber Conveyor Belts

Get Price Quote

We offer rubber conveyor belts. Our belts have found satisfactory customers in the domestic and the international export market with our clientele ranging iron & steel plants, coal, copper, gold mines, cement plants, thermal plants, fertilizers plant and ports to name a few. Jonson conveyor belts conform to all relevant indianinternational standards and are manufactured in a wide range to suit all applictaions.

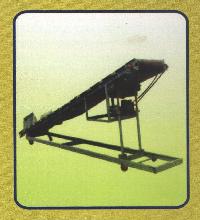

Belt Conveyor

Get Price Quote

Details Belt conveyor is a kind of machine that transfers the material continuously. The belt works under the effect of frictional force. It is not only the component to transfer the material but also the components to transfer the force. Advantage Roller Roller is the main part for power transmission. Carrier Roller Control horizontal positions; reduce the impact of material. Tensioning Gear Belt conveyor get tension to avoid slipping; deflection is under control. High Capacity High quality of belt conveyor; large dip angle and high delivery value conveying slipping and maturing is could be avoided. Product introduction Production capacity : 40-1000T/H Notice: this capacity is mean value and the specific production capacity is subject to clients’actual equipment configuration. Processable Material : granite marble basalt iron ore cobble shale bluestone coal cobblestone construction waste Range of Application : belt conveyor is the connection of machineries to make a complete system line. Belt conveyor is a kind of machine that transfers the material continuously. The belt works under the effect of frictional force. It is not only the component to transfer the material, but also the components to transfer the force. EMCC belt conveyor is advanced and simple in structure, easy to maintain. Transfer capacity is more higher, and transfer distance more longer. It is widely used in mining, metallurgical and coal industry to transfer sandy or lump material, or packaged material. In many situation, it is a very important component of nonstandard machinery. The belt conveyor is composed of standard parts, advanced and simple in structure, easy to maintain. They are widely used in mining, metallurgical and coal industry to transfer sandy or lump material, or packaged material. According to different transferring equipment, the transfer system can be one independently or multi-conveyors or combined with other transfer equipments. It can be installed horizontally or aslope to meet the needs of different transfer lines. The conveyor can be operated in the circumstance temperature range from -20℃ to +40℃. Temperature of transferred material by this belt conveyor should be lower than 50℃. Working principle Belt conveyor is composed of rollers and closed conveyor belt. There are two rollers one is for driving conveyor rotating another one is for changing the motor direction of conveyor. Head roller is drived by motor conveyor is draged by force of friction which is generated from head roller and conveyor. Head roller is often set in the discharging end to increase traction for a better dragging. Material is fed from feed end and falls on the rotating conveyor belt and discharged by conveyor delivery

Rubber Conveyor Belts

Get Price Quote

We are offering rubber conveyor belts. Rapid industrialisation has necessitated the use of conveyor belts which have proved to be the most cost-effective system for transportation of raw material & finished goods in any form, for any application. Jonson belting are manufactured in our most modern, fully automated plant, using the finest raw material inputs, under the strict vigil of qualified technical personnel. Our belts have found satisfactory customers in the domestic and the international export market with our clientele ranging iron & steel plants, coal, copper, gold mines, cement plants, thermal plants, fertilizers plant and ports to name a few. Jonson conveyor belts conform to all relevant indianinternational standards and are manufactured in a wide range to suit all applictaions.

Packing Belt Conveyor

Get Price Quote

Our company is engaged in designing and fabricating precision-engineered Packing Belt Conveyors. We are one of the prominent Manufacturers, Exporters & Suppliers of Packing Belt Conveyors. We offer them in varied specifications and provide individually tailored solutions as well. Interested buyers can get Packing Belt Conveyors from us in bulk and expect on time delivery of orders. Product Details : Application - Packing of empty Mono Carton / Cartons / Filled / Crates / Boxes in the packing line. Construction - M.S. Sliver / White Painted (S.S. Option Available) Height : Adjustable (as required) Width of Roller - 9" / 12" / 18" PVC coated canvas / Rubber Belt Imported food grade belt also available. Speed : Variable

Inspection Conveyor

Get Price Quote

Not just designing and manufacturing, but we make sure that the packaging of the products is also given the priority. Our packaging experts make use of quality packaging material to deliver the product undamaged. Ours is a well-established firm, located in New Delhi(India) and associated with leading names to fulfill varied demands of the buyers.

Slat Belt Conveyor

Get Price Quote

With strong industrial experience, we make sure that the packaging is done as per the stated norms, by this; the products that we deliver are absolutely safe from the getting damaged. Buyers prefer us for our practice of delivering the orders within the pre-decided time frame. Salient Features : Type : Portable/Fixed Belt Width : 400mm to 2000mm Speed : 35Mtr./min oras required Type of Bag : Jute/HDPE/Paper. Type : 3 Roll/2Roll/Flat. Application : Suger, Coal, Ash, Baggasse, Mud, Seed, Fartiliser etc.

steel cord belt

Get Price Quote

Belt Conveyor

Get Price Quote

Belt Conveyor

Get Price Quote

Details Belt conveyor is a kind of machine that transfers the material continuously. The belt works under the effect of frictional force. It is not only the component to transfer the material but also the components to transfer the force. Advantage Roller Roller is the main part for power transmission. Carrier Roller Control horizontal positions; reduce the impact of material. Tensioning Gear Belt conveyor get tension to avoid slipping; deflection is under control. High Capacity High quality of belt conveyor; large dip angle and high delivery value conveying slipping and maturing is could be avoided. Product introduction Production capacity : 40-1000T/H Notice: this capacity is mean value and the specific production capacity is subject to clients’actual equipment configuration. Processable Material : granite marble basalt iron ore cobble shale bluestone coal cobblestone construction waste Range of Application : belt conveyor is the connection of machineries to make a complete system line. Belt conveyor is a kind of machine that transfers the material continuously. The belt works under the effect of frictional force. It is not only the component to transfer the material, but also the components to transfer the force. EMCC belt conveyor is advanced and simple in structure, easy to maintain. Transfer capacity is more higher, and transfer distance more longer. It is widely used in mining, metallurgical and coal industry to transfer sandy or lump material, or packaged material. In many situation, it is a very important component of nonstandard machinery. The belt conveyor is composed of standard parts, advanced and simple in structure, easy to maintain. They are widely used in mining, metallurgical and coal industry to transfer sandy or lump material, or packaged material. According to different transferring equipment, the transfer system can be one independently or multi-conveyors or combined with other transfer equipments. It can be installed horizontally or aslope to meet the needs of different transfer lines. The conveyor can be operated in the circumstance temperature range from -20℃ to +40℃. Temperature of transferred material by this belt conveyor should be lower than 50℃. Working principle Belt conveyor is composed of rollers and closed conveyor belt. There are two rollers one is for driving conveyor rotating another one is for changing the motor direction of conveyor. Head roller is drived by motor conveyor is draged by force of friction which is generated from head roller and conveyor. Head roller is often set in the discharging end to increase traction for a better dragging. Material is fed from feed end and falls on the rotating conveyor belt and discharged by conveyor delivery end. Technical Parameters

Inspection Conveyor

Get Price Quote

Rubber Conveyor Belts

Get Price Quote

200 Meters Meter (MOQ)

Rubber Conveyor Belts

Get Price Quote

Rubber Conveyor Belts, Transmission Belts, Rubber Sheets

Rubber Conveyor Belt

Get Price Quote

Industrial Fabric, synthetic textiles, Transmission Belts, Rubber Sheets

Inspection Conveyor

Get Price Quote

Inspection Conveyor, PP Cap Sealing Machine, Ss Pallets, SS Cross Over Bench

Rubber Conveyor Belt

Get Price Quote

Industrial Rubber Conveyor Belts

Rubber Conveyor Belt

Get Price Quote

Automotive Tyres, tubes, threshers machines

Rubber Conveyor Belts

Get Price Quote

Rubber Conveyor Belts, Rubber Transmission Belts

Rubber Conveyor Belt

Get Price Quote

transmission rubber belts, stall mats, stable mats, V Belts, poly belts