Wide Throat Pumps

8,000 - 800,000 Per Piece

our progressive cavity pump features single helix metallic rotor and a double helix elastomer stator. pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. with rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. key benefits: positive displacement: generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. self-priming: inherently self-priming, operates on snore, eliminating the need for a foot valve. non-clog operation: effectively handles solids in suspension or high-solid-content media without the risk of clogging. less npsh requirement: demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. low rpm: minimizes degradation of shear-sensitive media, accommodating highly viscous materials. two-way operation: efficiently performs in either direction due to reversible rotation capabilities. quiet operation: rotors turning inside a resilient stator ensure minimal noise during operation. isolated bearing housing: enables contamination-free fluid pumping. universal joint coupling: superior to conventional joints, withstands angular loads and high axial forces, making it ideal for progressive cavity pumps. shaft sealing: external stuffing box for hassle-free maintenance of gland packing or mechanical seals without the need to dismantle the bearing housing. applications: refineries and petrochemicals chemicals and fertilizers explosives paints & varnish man-made fibers natural and synthetic rubber mining and construction starch, vegetable oils sanitary, ceramics and refractories cellulose sugar and distilleries soap and detergents cosmetics and toiletries pulp and paper effluent, waste and sewage water treatment fisheries steel alternative energy (biogas, ethanol)

Material : Carbon Steel,Cast Iron,Mild Steel,Stainless Steel

Driven Type : Electric

Power : 1-50kw,100-200kw,50-100kw

Pressure : 1-50kg/cm2

Type : Wide Throat Pumps,

Warranty : 2years

Country of Origin : India

Pump Speed : 100-1000RPM

Maximum capacity : 300 meter cube per hour

Maximum Temperature : 150 Degree C

...more

Small Progressive Cavity Pump

5,000 - 100,000 Per piece

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper Effluent, Waste and Sewage Water Treatment Fisheries Steel Alternative Energy (Biogas, Ethanol)

Power : Electric

Application : Mobile Pumps

Type : Progressive Cavity Pumps

Structure : Screw Pump

Country of Origin : India

Temperature : 1-80 Deg C,80-160 Deg C

Maximum capacity : 20 LPH to 500 LPH

Maximum Temperature : 150 Degree C

...more

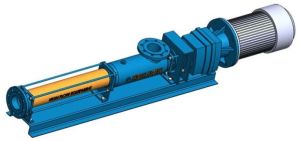

single screw pumps

8,000 - 800,000 Per Piece

1 Piece (MOQ)

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Effluent, Waste and Sewage Water Primary and secondary process sludge Sludge dewatering and transfer Sludge thickening and transfer Sludge blending and holding Controlled flocculent pumping Mixing and dosing conditioning agents AD sludge recirculation and transfer Heavy sludge cake transfer Imported and tankered in sludge transfer Shear-sensitive processes Sludge maceration and grinding Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper

Size : Various

Type : Progressive Cavity Pump

Brand Name : HFE

Material : Cast Iron, Cast Steel, Cast Stainless Steel, Fabricated Steel and Stainless Steel

Length : Depending on Pump Size

Application : Industrial

Weight : Depending on Pump Size

Shelf Life : 10 Years

Condition : New

Head : 300 meter

Viscosity : Upto 300000 cst

...more

Single Screw Pump Retrofit Spares

5,000 - 500,000 Per piece

progressive cavity pump spare parts rotor-stainless steel 410/304/316/316l stator- nbr/ epdm/ viton/ white nbr coupling rod-stainless steel 410/304/316/316l mechanical seals joint rubber seal and other components our spares benefit : faster deliveries all major pump manufacturers pc pump’s spare parts available satisfaction or your money back 12 months warranty

Material : Stainless Steel

...more

Rubber Stator for Screw Pump

5,000 - 500,000 Per piece

progressive cavity pump spare parts rotor-stainless steel 410/304/316/316l stator- nbr/ epdm/ viton/ white nbr coupling rod-stainless steel 410/304/316/316l mechanical seals joint rubber seal and other components our spares benefit : faster deliveries all major pump manufacturers pc pump’s spare parts available satisfaction or your money back 12 months warranty

Material : Cast Iron,Mild Steel,Stainless Steel

Country of Origin : India

...more

Progressive Cavity Pumps

3,000 - 500,000 Per piece

1 Piece (MOQ)

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Effluent, Waste and Sewage Water Primary and secondary process sludge Sludge dewatering and transfer Sludge thickening and transfer Sludge blending and holding Controlled flocculent pumping Mixing and dosing conditioning agents AD sludge recirculation and transfer Heavy sludge cake transfer Imported and tankered in sludge transfer Shear-sensitive processes Sludge maceration and grinding Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper

Power : Electric, Engine

Application : Mobile Pumps, Industrial

Certification : ISO 9001:2008 Certified

Type : Progressive Cavity Pumps, Progressive Cavity Pumps

Structure : Screw Pump

Country of Origin : India

Temperature : 1-80 Deg C, 160-240 Deg C, 80-160 Deg C

Viscosity Range : 1-50000 Cp, 50000-100000 Cp, Upto 200000 Cp

...more

Progressive Cavity Pump Rotor and Stator

5,000 - 500,000 Per piece

progressive cavity pump spare parts rotor-stainless steel 410/304/316/316l stator- nbr/ epdm/ viton/ white nbr coupling rod-stainless steel 410/304/316/316l mechanical seals joint rubber seal and other components our spares benefit : faster deliveries all major pump manufacturers pc pump’s spare parts available satisfaction or your money back 12 months warranty

Type : Progressive Cavity Pumps

Country of Origin : India

...more

positive displacement pumps

8,000 - 800,000 Per Piece

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper Effluent, Waste and Sewage Water Treatment Fisheries Steel Alternative Energy (Biogas, Ethanol)

Material : Carbon Steel,Cast Iron,Metal,Mild Steel

Driven Type : Electric

Color : Green

Condition : New

Pressure : High

Voltage : 440V

Type : Positive Displacement Pumps

Phase : Three Phase

Warranty : 2yrs

Country of Origin : India

Speed : 1400rpm

Maximum capacity : 300 meter cube per hour

Maximum Temperature : 150 Degree C

...more

pc pumps

5,000 - 500,000 Per piece

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper Effluent, Waste and Sewage Water Treatment Fisheries Steel Alternative Energy (Biogas, Ethanol)

Power : Electric

Pressure : High Pressure

Application : Mobile Pumps

Type : Progressive Cavity Pumps

Structure : Screw Pump

Country of Origin : India

Temperature : 1-80 Deg C,80-160 Deg C

Viscosity Range : 1-50000 Cp

Maximum capacity : 20 LPH to 500 LPH

...more

Metering and Dosing Screw Pump

5,000 - 500,000 Per piece

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper Effluent, Waste and Sewage Water Treatment Fisheries Steel Alternative Energy (Biogas, Ethanol)

Brand Name : HFE

Condition : New

Power : 1-3kw,3-6kw,6-9kw

Pressure : 24Bar

Warranty : 2years

Country of Origin : India

Pump RPM : 1400

Maximum capacity : 20 LPH to 500 LPH

Maximum Temperature : 150 Degree C

...more

helical rotor pumps

8,000 - 800,000 Per Piece

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper Effluent, Waste and Sewage Water Treatment Fisheries Steel Alternative Energy (Biogas, Ethanol)

Driven Type : Electric

Power : 0-5Kw,10-15Kw,5-10Kw

Pressure : High Pressure

Application : Beverage Industries,Chemical Industries,Food Industries,Pharmaceutical Industries,

Voltage : 220-440V

Type : Helical Rotor Pumps

Country of Origin : India

Running RPM : 0-1400

Maximum capacity : 300 meter cube per hour

Maximum Temperature : 150 Degree C

...more

External Gear Pump

5,000 - 500,000 Per piece

1 Piece (MOQ)

External Gear Pumps for fluid transfer handles a wide range of liquids, from thinner to thicker and even corrosive substances with minimal or no lubrication. These compact and reliable pumps effortlessly manage fluids at temperatures reaching up to 250 degrees Celsius. Key Features:1. Pump Design: Ensures efficient and rapid fluid transfer, making it suitable for high-capacity applications.2. Compact and Reliable: The pump's compact design ensures space efficiency while maintaining reliability in operation.3. Low Noise Operation: Provides a quiet and smooth pumping experience, minimizing noise disruptions.4. Higher Efficiency: Maximizes fluid transfer efficiency, contributing to overall operational effectiveness.5. Easy Maintenance: Simplifies upkeep, reducing downtime and ensuring seamless pump performance.6. Built-In Pressure Relief Valve: Enhances operational safety by preventing excessive pressure buildup.7. Material Options: Choose from Cast Steel, SS 304, SS 316, SS 316L based on your specific application requirements.8. Bearing Options: Select from Bronze Bush, Teflon Coated DU, or Ball bearings for optimal performance.9. Sealing Options: Tailor the sealing mechanism with Oil Seal, Gland Ring, Single or Double Mech seals.10. Gear Design Options: Opt for Single or Twin Gear configurations with a Herringbone gear design.11. Maximum Capacity: Impressive handling capacity of up to 100m3/hr for demanding applications.12. Max Pressure Head: Capable of handling pressures up to 30 Bar, ensuring robust performance.13. Maximum Temperature: Handles fluids at temperatures reaching up to 250 degrees Celsius.14. Maximum Viscosity: Suitable for fluids with viscosities up to 10,000 cSt.Some of the pump applications : Additives LSHS and Oils with 40 to 50 Microns Soft Impurities Asphalt Aviation Fuel Base Oils Bitumen Castor Oil Clean Lube Oils Corrosive and Hygienic Liquids Coolant Crude Oil Crude Palm Oil (CPO) Fire Fighting Foam Fuel Oil High-Speed Diesel (HSD) Hydraulic Oils Kerosene Lube Oil Naphtha Oils with Soft Impurities (10 to 20 Microns) Petrol Turbine Oil

Brand Name : HFE

Driven Type : Electrical

Pressure : 0-50Bar

Motor Power : 5 HP

Application : Commercial, Industrial

Type : External Gear Pumps

Frequency : 50Hz, 60Hz

Phase : Triple Phase

Country of Origin : India

Pump Speed : 1440Rpm

Discharge Rating : 1600LPM

...more

eccentric screw pump

8,000 - 800,000 Per piece

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper Effluent, Waste and Sewage Water Treatment Fisheries Steel Alternative Energy (Biogas, Ethanol)

Material : Carbon Steel,Cast Iron,Mild Steel,Stainless Steel

Power : 1-50kw,100-200kw

Pressure : 1-50kg/cm2

Application : Fluids With High Viscosity,Pulp Etc,Slurry

Fuel : Electricity

Country of Origin : India

Warrenty : 2years

Pump Speed : 100-1000RPM

...more

eccentric rotor pump

5,000 - 100,000 Per piece

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper Effluent, Waste and Sewage Water Treatment Fisheries Steel Alternative Energy (Biogas, Ethanol)

Power : 0-5Kw,10-15Kw

Pressure : Low Pressure,Medium Pressure

Application : Beverage Industries,Chemical Industries,Food Industries,Pharmaceutical Industries

Type : Helical Rotor Pumps

Country of Origin : India

...more

Compact Mini Progressive Cavity Pump

5,000 - 100,000 Per piece

our progressive cavity pump features single helix metallic rotor and a double helix elastomer stator. pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. with rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. key benefits: positive displacement: generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. self-priming: inherently self-priming, operates on snore, eliminating the need for a foot valve. non-clog operation: effectively handles solids in suspension or high-solid-content media without the risk of clogging. less npsh requirement: demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. low rpm: minimizes degradation of shear-sensitive media, accommodating highly viscous materials. two-way operation: efficiently performs in either direction due to reversible rotation capabilities. quiet operation: rotors turning inside a resilient stator ensure minimal noise during operation. isolated bearing housing: enables contamination-free fluid pumping. universal joint coupling: superior to conventional joints, withstands angular loads and high axial forces, making it ideal for progressive cavity pumps. shaft sealing: external stuffing box for hassle-free maintenance of gland packing or mechanical seals without the need to dismantle the bearing housing. applications: refineries and petrochemicals chemicals and fertilizers explosives paints & varnish man-made fibers natural and synthetic rubber mining and construction starch, vegetable oils sanitary, ceramics and refractories cellulose sugar and distilleries soap and detergents cosmetics and toiletries pulp and paper effluent, waste and sewage water treatment fisheries steel alternative energy (biogas, ethanol)

Power : Electric

Pressure : High Pressure

Application : Mobile Pumps

Type : Progressive Cavity Pumps

Structure : Screw Pump

Country of Origin : India

Temperature : 1-80 Deg C,80-160 Deg C

Viscosity Range : 1-50000 Cp,50000-100000 Cp

Maximum capacity : 20 LPH to 500 LPH

...more

Close Coupled Flange Single Screw Pump

8,000 - 8,000,000 Per piece

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper Effluent, Waste and Sewage Water Treatment Fisheries Steel Alternative Energy (Biogas, Ethanol)

Automatic Grade : Automatic,Manual,Semi Automatic

Power : 1Bhp,2Bhp,3Bhp,5Bhp

Pressure : High Pressure

Type : Close Coupled Pumps

Theory : Rotary Pump

Warranty : 2years

Country of Origin : India

Maximum capacity : 300 meter cube per hour

Maximum Temperature : 150 Degree C

...more

Chemical Dosing Single Screw Pump

5,000 - 500,000 Per piece

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper Effluent, Waste and Sewage Water Treatment Fisheries Steel Alternative Energy (Biogas, Ethanol)

Brand Name : HFE

Condition : New

Power : 1-3kw,3-6kw,6-9kw,9-12kw

Pressure : 24Bar

Pump Power : 2Hp,3Hp,5Hp

Voltage : 440V

Type : Chemical Dosing Pumps

Warranty : 2years

Country of Origin : India

Pump RPM : 1400

Maximum capacity : 20 LPH to 500 LPH

Maximum Temperature : 150 Degree C

...more

Bare Shaft Flange Single Rotor Pump

8,000 - 800,000 Per piece

Our Progressive Cavity Pump features single helix metallic rotor and a double helix elastomer stator. Pumping principle establishes sealing lines along the rotor's axis, ensuring stability in both static and dynamic conditions. With rotation of rotor within the stator, fluid-filled cavities progress seamlessly from suction to discharge, providing a uniform, metered, and non-pulsating flow. Key Benefits: Positive Displacement: Generates progressive cavities for a consistent flow, independent of rotational speed, with capacity proportional to speed. Self-Priming: Inherently self-priming, operates on snore, eliminating the need for a foot valve. Non-Clog Operation: Effectively handles solids in suspension or high-solid-content media without the risk of clogging. Less NPSH Requirement: Demonstrates effectiveness in high vacuum conditions, with suction lift capabilities up to 9 meters. Low RPM: Minimizes degradation of shear-sensitive media, accommodating highly viscous materials. Two-way Operation: Efficiently performs in either direction due to reversible rotation capabilities. Quiet Operation: Rotors turning inside a resilient stator ensure minimal noise during operation. Isolated Bearing Housing: Enables contamination-free fluid pumping. Universal Joint Coupling: Superior to conventional joints, withstands angular loads and high axial forces, making it ideal for Progressive Cavity Pumps. Shaft Sealing: External stuffing box for hassle-free maintenance of Gland Packing or Mechanical Seals without the need to dismantle the bearing housing. Applications: Refineries and Petrochemicals Chemicals and Fertilizers Explosives Paints & Varnish Man-Made Fibers Natural and Synthetic Rubber Mining and Construction Starch, Vegetable Oils Sanitary, Ceramics and Refractories Cellulose Sugar and Distilleries Soap and Detergents Cosmetics and Toiletries Pulp and Paper Effluent, Waste and Sewage Water Treatment Fisheries Steel Alternative Energy (Biogas, Ethanol)

Brand Name : HFE

Material : Alloy Steel,Cast Iron,Stainless Steel

Pressure : 24Bar

Type : Bare Shaft Pumps,

Fuel : Motor or Engine Driven

Structure : Metallic

Country of Origin : India

Maximum capacity : 300 meter cube per hour

Maximum Temperature : Upto 150 Degree C

...moreBe first to Rate

Rate ThisOpening Hours