Worm Gears

Material : MS, Carbon Steel, Alloy Steel or any other custom specific material as per SAE, AISI, BS: and ASTM.

Type : Single, Double And Multiple.

Twin Lobe Blower

we are leading supplier of this product.

Type : Water and Air Cooled.

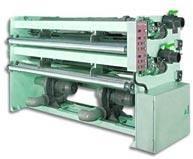

Thin Blade Rotary Cutting Machine

Effective Designed Speed: 150 metre/min Effective Designed Width Range: 1400mm – 2500mm Fitted with Frequency Controller Device Clean cutting edge with the help thin blades and manual and automatic grindstone. Four Blades with six lines and five blades with eight lines are custom tailored accordingly. Convenient paper transmission with the help of Pre-Compressed Paper feeding Motorized Lifting, lowering and transverse movement

...more

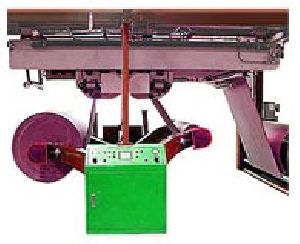

Suction Brake Stand

Effective Designed Speed- 150-200 metre/min Effective Designed Width Range: 1200-2500 mm Fitted with Speed Controller in order to have proper synchronisation with the production line Electro-motor to align the width of the corrugated paper Vacuum control system in order to provide the enhanced fluting quality With two sets of head panel, operations can take place on the bridge as well as on the control system of the Double Baker

...more

Stacking Unit

Electric or Automatic paper receiving arm. Stacking Height of 1600 mm Elevation of the collection platform stimulated by solid chains Automatic paper receiving plates and Air pressure movements Adjustable paper receiving arm belt. Also available as an individual attachment

...more

Spur Gearbox

we are leading supplier of this product.

Material : Designed, Fabricated and Casted as per Customer's Specifications.

Type : Single, Double and Multiple Stages.

Sprockets

Material : MS, Carbon Steel, Alloy Steel or any other custom specific material as per SAE, AISI, BS: and ASTM.

Type : Simplex and Duplex

Splined Shafts

Material : MS, Carbon Steel, Alloy Steel or any other custom specific material as per SAE, AISI, BS: and ASTM.

Splicer

Effective Width: 1400-2500 mm Effective Designed Length: 2000-3000 mm Dual Relaxed Roller system with aluminium make transfer roll Uninterrupted slicing process due to web tension paper control Compatible with every production management system Slicing success rate of over 99%

...more

Slotting Unit

Automatic resetting with electrical internal teeth grooving and carton height adjustment. Urethane Pre- pressing transmission wheel to avoid crushing of the board Alternative movement of up-down knives, positional function of the slotting knife. 360 degree facet adjustment by electric gears Also available as an individual attachment

...more

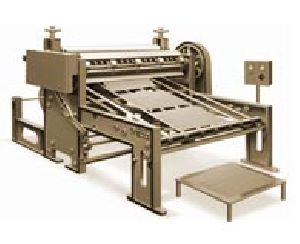

Sheet Pressing Machine

Used for consistent setting up of the corrugated sheets after pasting process. Hydraulic Lift and Pressing Control Heavy Duty Steel Structure Motorised switch and starter arrangement Fitted with Waterproof ply and steel plates.

...more

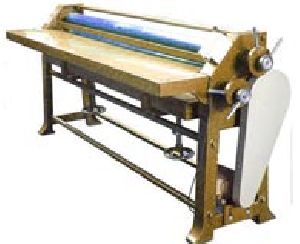

Sheet Pasting Machine

This machine is used for the application of glue on the surface of various ply-corrugated sheets. Simple and elegant design. 4 ROLLERS (Three hard chrome coated iron rollers and One Ebonite roller) or 3 ROLLERS (Three hard chrome coated iron rollers). Stainless Steel adjustable tray for Gum Top and doctor roller manual adjustment Electric Starter and motor Limited and specific quantity of glue application in order to reduce the corrugated roller impression on the sheet.

...more

Sheet Conveyor

Effective Designed Speed Range- 100-180 meter/min Effective Width Range- 1200-2800mm Custom Tailored Length between 3-6 metres Automatic movement with the help of heat-resistant conveyor belt Fitted with Electro-magnetic motor to synchronize the speed with respect to production line Electronic control of the paperboard for height and number variations. Automatic stacking, Motorized transverse and Pneumatic Lifting

...more

Shaft Less Hydraulic Roll Stand

Effective Paper Roll Diameter- 350mm-1500 mm Effective Reel Width Range- Min- 600mm. Max- Custom Tailored. Effective Paper Width Range- 800mm-2500mm Average Designed Speed- 150 Metre/min. Hydraulic control for lifting, lowering, clamping and releasing. Individual Lifting Movement Air Brakes or Multipoint Brakes Controlling Paper Tension Reel Lifting Weight Capacity- 1000Kgs- 30000Kgs

...more

Shaft Less Electrical Roll Stand

Effective Paper Roll Diameter- 350-1500 mm Effective Reel Width Range- Min- 600mm. Max- Custom Tailored Effective Paper Width Range- 800mm-2500mm Average Designed Speed- 120 Metre/min. Motorised adjustment for lifting, lowering, clamping and releasing. Swing Lifting Movement Heavy Duty Steel Wings for holding Paper rolls. Heavy Duty Lever to control the movement of Lifting Wings Perfect Synchronisation with running Corrugation Line Manual, Air or Multipoint Brakes controlling paper tension

...more

Semi-Automatic Stitching Machine

Automatic Paper Feeding Provision for Single as well Double Nailing Quick and easy order change Automatic Counter Ejector Mechanical-Automatic Interface Control Touch Screen Panel

...more

Semi- Automatic Gluing Machine

This machine is used for folding and gluing all kinds of corrugated paperboards. Front conveyor and changing function Uniform Pasting Design Electrical Control Panel Custom made as per required Corrugated Paperboard or Sheet size.

...more

Semi-Automatic Flute Laminator

Bottom Paper Vacuum Feeding/ Manual Feeding Electric Control Positioning of Bottom Paper Panel Flexible Positioning of the Front Facet Automatic and Recyclable Glue Application System High Speed (50-80 Metre/min) Custom made as per required Corrugated Paperboard or Sheet size.

...more

Rotary Slotting Machine

Rotary Creasing and Slotting Machine Operation Panel of 6mm plates with manual chain feeding system, Chrome Plated and grinded shafts, Spray Lubrication system of Gears, PLC enabled operational system, Four knives grouping for creasing, three for slotting, two for partitioning and one for angle cutting. Fitted with Frequency Controller, 360-degree rotational movement of grooving cutters.

...more

Rotary Sheet Cutter

This machine is used to cut Kraft Liner Paper or 2 Ply Corrugated Board into sheets without damaging the flutes (In the case of Corrugated Board). It can be used independently as well as an attachment to the single facer in order to facilitate accurate sheet cutting process. Fitted with Oil Lubrication Pump (OLP) in order to provide continuous and consistent supply of oil to the Gear system of the machine Comprehensive feature of the machine is the Excel Make PIV Gear Box fitted with imported chain in order to adjust the sheet size to be cut with respect to the Gear Ratio. Perfect Synchronisation of the machine and Single facer, with the provision of AC Drive. Improved Cutting Process with Four Edge cutting. Delivery Conveyor in order to stack Cut Sheets

...more

Rotary Die Cutter

Used for Die-Cutting and Creasing Requisite attachment for solid and calliper boards Chain/Vacuum Paper Feeding System Automatic Transverse Movement High Precision Grinded Rotary Roller Efficient Heat Treatment System for Gears Installed with automatic repairing system for upper roller 360-degree rotational movement of grooving cutters.

...more

Rotary Creasing Machine

Operation Panel of 6mm plates with manual chain feeding system Chrome Plated and grinded shafts Spray Lubrication system of Gears PLC enabled operational system Four knives grouping for creasing, three for slotting, two for partitioning and one for angle cutting. Fitted with Frequency Controller 360-degree rotational movement of grooving cutters

...more

Ring Gears

Material : MS, Carbon Steel, Alloy Steel or any other custom specific material as per SAE, AISI, BS: and ASTM.

Type : Internal & External - Spur and Helical.

Printing Unit

High quality steel rollers with hard chrome/tungsten coated electroplated surface High-speed plate changing device. Automatic Re-Setting Automatic Digital Axis Adjustment Electromagnetic Clutch braking system keeping the position of intrinsic gear fixed. High quality grinded rubber gear. Also available as an individual attachment

...moreOpening Hours