single bed mink blanket

400 - 800 Per Piece

5000 Piece (MOQ)

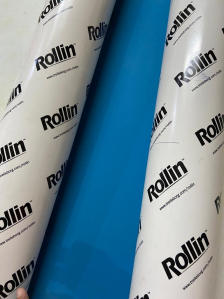

Commercial Offset Printing Rubber Blanket

900 Per Piece

25 Piece (MOQ)

Best Deals from Blankets

Cotton Dohar Blanket

2,000 - 2,500 Per Piece

10 Piece (MOQ)

Leaf Floral Design Cotton Dohar

9,050 Per Piece

10 Piece (MOQ)

Self Adhesive and Underlay Blanket

Get Price Quote

Avail from us this Self-Adhesive and Underlay Blanket of excellent quality. The Self-Adhesive and Underlay Blanket has gum on backside of the blanket that sticks to the cylinder of the presses. The Self-Adhesive and Underlay Blanket is used in Stationary Printing Machines.

fire blankets

395 - 1,250 Per Piece

1 Piece (MOQ)

Our organization stocks the items in mass. Therefore, we can serve mass/ retail requirements without hassle and make sure delivery of products is swift. The raw material that is used for manufacturing superior grade products is sourced from the reliable places after complete quality confirmation. These Fire Blankets are very famous owing to their high-quality and durability.

Royal Green Offset Printing Blanket

3,000 - 4,000 Per Square yard

50 Square yard (MOQ)

Hemotherm Blanket

18,000 Per Piece

2 Piece (MOQ)

Golden Mink Blanket

400 - 2,500 Per Piece

50 Piece (MOQ)

Electric Heating Blanket

Get Price Quote

50 Piece (MOQ)

Fire Blanket

Get Price Quote

100 Piece (MOQ)

Throw Blanket

Get Price Quote

Wool Blankets

1,100 - 1,850 Per Piece

10 Piece(s) (MOQ)

Product Description A natural fiber, most luxurious softest & warmest. Our cashmere throws are woven by hand with all natural fibers the most exclusive only the finest cashmere fibers with with decorative fringed ends both sides. Material:- Pashmina Wool (Weave like Twill,Herringbone,Matty) Pure Cashmere Available size: * 135 cms x 200 cms + both side fringes * 150 cms x 180 cms + both side fringes Size and colours can be made as per requirement.

Ceramic Fiber Blanket

2,000 - 4,000 Per Piece

1 Piece (MOQ)

Wool Jamawar Throws

Get Price Quote

We are offering to our customer extremely beautiful Wool Jamawar Throws. Our Wool Jamawar Throws are designed with some complex and intricate designs which give them a unique look. They can be used as a wall hanging, table cover to give a fresh look to your house. However, they can also be used as a shawl. We offer the Wool Jamawar Throws in different designs with some beautiful color options.

korean blankets

Get Price Quote

Woolen Hospital Blankets

Get Price Quote

We manufacture export hospital blankets in varying sizes, colors and weights in economy and deluxe qualities in solid colors, plaids and jacquards in woollen, acrylic, cotton leno and fleece.

Fire Safety Blanket

Get Price Quote

Hospital Blankets

400 Per Piece

100 Piece(s) (MOQ)

Organic Muslin Baby Swaddle

Get Price Quote

50 Piece(s) (MOQ)

We are pfferomg organic muslin baby swaddle. Bumchum muslin products are carefully designed to preserve the goodness of muslin fabric, and to encourage its multiple uses as the baby grows. Delicate and breathable, these products are a perfect addition to any nursery. key features of cotton muslin â· versatile: generous size of blankets to make them useful for multiple functions as the baby grows â· light weight and breathable, makes them cool in summer and warm in winter. â· unique: modern and aesthetically pleasing designs and colors designed exclusively for bumchum. â· comfortable: physicians recommend lightweight fabrics to help prevent overheating and reduce the risk of sids. â· durable : can be used for multiple purposes and the fabric gets softer with every wash