Cellulose Filter Pads

Get Price Quote

We manufacture cellulose filter pads that are used in various industries viz. Drugs and pharmaceuticals, foods and beverages etc.

Cellulose Pads

Get Price Quote

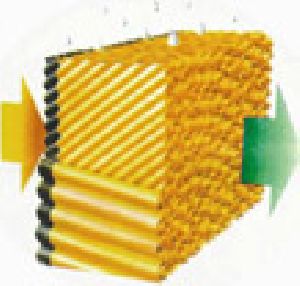

We are counted among the most trusted Suppliers of quality Cellulose Pads which are extensively used in various applications. Our Cellulose Pads are made using cross corrugated cellulose paper, coated with anti riot, rigidifying wetting resins. The Cellulose Pads offered by us are having the capability to retain and absorb water to provide maximum cooling efficiency. Our Cellulose Pads are available at industry leading prices. Standards SizesDepth : 100mm, 150mm, 200mmWidth : 300mm, 600mmHeight : 900mm, 1200mm, 1500mm, 1800mmFlute Dia : 7mm

Best Deals from Cellulose Pad

Cellulose Pad

Get Price Quote

From Delhi, India, we offer Cellulose Pad to fulfill various needs of different industry. The comany is backed by a team who utilize the latest techniques for manufacturing Cellulose Pad as per industry standards, thus quality is assured. Apart from this, we also provide Cellulose Pads in different grades to meet the buyer’s demands. Customized solutions are available, at feasible prices. We are one of the prominent names in manufacturing depth filter pads which have the following essentials. Description : Type - Coarse, medium, fine, precoat, strelizing filtration Raw material - Pure cellulose, cotton-linter, hyflow powder (cellulose-celite) Size - Round Formats / Disc- 30mm to 1000mm (central corner hole size as per demand) Square formats:all sizes upto 1000 mm*1700mm special sizes on demand Fluid - Beer, IMFL Wine, chemicals, fruit juice, vegetable oils, water, drug, syrup, injectable, IV fluid, liquid sugar, liquors, edible oils, printing inks, paints, varnishes, hydraulic fluids, antibiotic, transformer and governor oils. Applications : Distillery, breweries, pharmaceuticals, cosmetics, food industry, sugar industry and chemical industry.Main Constituents : Cellulose/Cotton Filter Pads Cellulose Filter Pads Nonwoven Cotton Saturated Filter Pads. Nonwoven (I.E Needle Punched) Filter Fabrics are categorized as per the fiber used:- Polyproplene Nonwoven Filter Fabric/Pads Polyester Nonwoven Filter Fabric/Pads

Water Retention Pads

Get Price Quote

Water retention pads water retention pads (cellulose pads) work on a simple principle of cooling with the help of water. Water flow from top to bottom of the pad and the air is sucked through the cellulose where the air cools down with the help of water, thus the warm air cools down and thus cools the temperature inside the greenhouse.

Standard Motor Cellulose Pad

1 - 450 Per Square Feet

500 Square Feet (MOQ)

Cellulose Cooling Pad

Get Price Quote

Cellulose cooling pad apart form manufacturing the fans for various applications, vct make the cellulose pad, made by these thailand and italy various companies in india and are well established with respect to poultry, horticulture (green house) and industrial applications. The evaporative cooling pad (ecp), made of cellulose paper is engineered from cross-sectional, specially treated flute media capable of absorbing and retaining water to provide the maximum cooling efficiencies. The cellulose media is treated with stiffening and wetting agents to provide the cooling without any water carryover. The pads are designed for tropical and subtropical countries, ensures greatest performance during summer seasons. Mixed esters of cellulose (mce) or cellulose acetate (ca) is best for microbiology and environment monitoring test. Contrasting grid lines facilitate counting colonies on the filter surface and are tested to assure freedom from grid line inhibition. The membrane solutions mce membranes are also tested for freedom from grid line inhibition and optimal color reactions on appropriate test media. Features the cellulose pad is cross corrugated coated with anti rot, rigidify & wetting resins. The 150 vapur pad are made for maximum efficiency, at minimum pressure drop.the pad media is treated with anti-rot and rigidify resins. The media is cross-corrugated to maximize the mixing of air and water. Saturation efficiency ranging from 50 to 98% can be achieved depending upon air velocity and depth of the cooling pad. Air flows horizontally, while the re-circulating water flows vertically, through the pad. The water is collected at bottom of the pad and is re-circulated, again by a pump through the unique gutter system made of g. I. Sheet. Availability:- absorbent pads sterile mixed cellulose ester (mce) filter petri dishes sterile cellulose acetate filter

Cellulose Pad

250 Per Square Feet

100 Square Feet (MOQ)

Cell Deck

Get Price Quote

With the support from our meticulous workforce, we are introducing an extensive array of Cell Deck. The offered product is manufactured using superior quality basic material and advanced technology with the set industry standards. Further, our offered pad undergoes stringent test to make sure that offered range is free from any kind of manufacturing defect. Features: Premium quality Finely finished Durability Applications: Live stocks Greenhouses Gas Turbine Pre Cooler For Air Cooled Condenser Spray Painting Booth Industrial Applications Commercial Applications Humidification.

Energy Efficient Honeycomb Celdek Cellulose Pad

280 Per Square Feet

100 Square Feet (MOQ)

energy efficient honeycomb celdek cellulose pad we at dp engineers manufacturers the energy efficient honeycomb celdek cellulose pads, they are designed with high water to air contact area to promote water evaporation. energy efficient honeycomb celdek cellulose pads are made from cellulose sheets in a honeycomb structure. it has a higher saturation efficiency and much longer life span. energy efficient honeycomb celdek cellulose pads normally last 4-5 years depending on water quality. currently we are producing 2 models of dp engineers energy efficient honeycomb celdek cellulose pads 5090 & 7090 with the flute size of 5 mm and 7 mm. energy efficient honeycomb celdek cellulose pads for domestic air coolers, industrial air coolers, ahu's, hvac's.it is made from europe's best energy efficient honeycomb celdek cellulose pads.dynea's best resin and glued with american material. key benefits of the product: high strength non hazardous & environment friendly for use rust resistant & good water absorption longer pad life, cost effective solution light in weight & low maintenance

Cellulose Pad For Poultry

Get Price Quote

Healthiest and most energy efficient solution for fastest growth of chicks

Cellulose Cooling Pad

Get Price Quote

cellulose cooling pad apart form manufacturing the fans for various applications,the cellulose pad, made by these thailand and italy various companies in india and are well established with respect to poultry, horticulture (green house) and industrial applications. the evaporative cooling pad (ecp), made of cellulose paper is engineered from cross-sectional, specially treated flute media capable of absorbing and retaining water to provide the maximum cooling efficiencies. the cellulose media is treated with stiffening and wetting agents to provide the cooling without any water carryover. the pads are designed for tropical and subtropical countries, ensures greatest performance during summer seasons. mixed esters of cellulose (mce) or cellulose acetate (ca) is best for microbiology and environment monitoring test. contrasting grid lines facilitate counting colonies on the filter surface and are tested to assure freedom from grid line inhibition. the membrane solutions mce membranes are also tested for freedom from grid line inhibition and optimal color reactions on appropriate test media. features :- the cellulose pad is cross corrugated coated with anti rot, rigidify & wetting resins. the 150 vapur+ pad are made for maximum efficiency, at minimum pressure drop.the pad media is treated with anti-rot and rigidify resins. the media is cross-corrugated to maximize the mixing of air and water. saturation efficiency ranging from 50 to 98% can be achieved depending upon air velocity and depth of the cooling pad. air flows horizontally, while the re-circulating water flows vertically, through the pad. the water is collected at bottom of the pad and is re-circulated, again by a pump through the unique gutter system made of g. i. sheet.

Cellulose Pad

Get Price Quote

Apart form manufacturing the fans for various applications, AASTHA markets the Cellulose Pad, made by various companies in India as well as abroad like Hutek Thailand, Munters Sweden/ Italy and Glacier America The Evaporative Cooling Pad, made of cellulose paper is engineered from cross-sectional, specially treated flute media capable of absorbing and retaining water to provide the maximum cooling efficiencies. The cellulose media is treated with stiffening and wetting agents to provide the cooling without any water carryover. The pads are designed for tropical and subtropical countries, ensures greatest performance during summer seasons. The Pad media is treated with anti-rot and rigidifying resins. The media is cross-corrugated to maximize the mixing of air and water. Saturation efficiency ranging from 50 to 98%, can be achieved depending upon air velocity and depth of the cooling pad. Air flows horizontally, while the re-circulating water flows vertically, through the pad. The water is collected at bottom of the pad and is re-circulated , again by a pump through the unique gutter system made of G. I. Sheet.

Roots Air Premium Quality Imported Cellulose Pads

Get Price Quote

Evaporative Cooling Pad with exclusive cross fluted configuration is a contact medium specially engineered for direct evaporative cooling and humidification of air. The Cooling Pad is made of corrugated sheets which are assembled in self-supporting pads of light-weight sturdy construction. Evaporative Cooling Pad is manufactured from a special cellulose paper, impregnated with insoluble antirotsalts, rigidifying saturants and wetting agents. OPERATION Like all evaporative coolers, Evaporative Cooling Pad relies entirely on evaporation of water for cooling and humidification. The waterfalls by gravity through the pad forming a thin water film that throughly covers the internal pad surface. The air passes horizontally through the pad in the open space between the sheets. Due to the pad geometry, turbulent contad is established between the water and the air which induces a highly efficient heat and moister transfer.

Hutek Air Washers Cellulose Pads

650 Per Square Feet

200 Square Feet (MOQ)

Honeycombed cellulose cooling pads

Get Price Quote

We are offering honeycombed cellulose cooling pads. we are delighted to introduce our selves as the supplier of honeycombed cellulose cooling pads for industrial and domestic air cooler

Cellulose Paper Pads

Get Price Quote

Cellulose Paper Pads, Air Washers, forward curved centrifugal fans

Cellulose Paper Filter Pads

Get Price Quote

We deal in various types of products for Fuel/Oil Filteration with customised Gsm and Thickness: Cellulose Filter Pads

Cellulose Paper Pads

Get Price Quote

Cellulose Paper Pads, bags filters, Pre Fabricated Duct, Air Washer

Cellulose Pad

Get Price Quote

Cellulose Pad, Air Filters, Fume Extraction System, kitchen fans

Evaporative Cellulose Cooling Pads

Get Price Quote

Evaporative Cellulose Cooling Pads, cabinet air conditioner