Chemical Industry Effluent Treatment Plant

2,350,000 Per Set

1 Set (MOQ)

Labsa Plant

Get Price Quote

1 Pieces (MOQ)

Best Deals from Chemical Plants

Stainless Steel Storage Tank

Get Price Quote

1 Piece (MOQ)

stainless steel tanks

25,000 - 35,000 Per Piece

5 Piece (MOQ)

Stainless Steel Tank

Get Price Quote

STAINLESS STEEL TANK FOR OZONATION & STORAGE

Stainless Steel Storage Tank

Get Price Quote

1 Piece (MOQ)

Bitumen Emulsion Plant

Get Price Quote

The fully computerized plant capable of producing 12 TPH Bitumen Emulsion of very high quality has been imported from ENH Engineering, Denmark, world leaders in Asphalt modification machinery manufacturing. A fully equipped laboratory with all testing facilities complements the Emulsion manufacturing plant studded with the most advanced PILOT PLANT for making trial samples.

Chemical Machinery

Get Price Quote

We are supported by a well-structured warehousing facility wherein we keep a large stock of products. This unit facilitates us to meet urgent and massive requirements of the customers. We guarantee to make on time delivery, as we have an extensively spread network of logistic facility providers and dealers.

oleochemical plant

10,000,000 - 20,000,000 Per Ton

100 Kilometer (MOQ)

To create free fatty acids and glycerine the fats and oils are hydrolysed in a process of splitting. A splitting plant operates in both the continuous and batch mode. The plant temperatures can range from 210 – 250 degrees Celsius and the working pressure may be between 30 to 60 bars. These conditions have been assumed keeping in mind no addition of catalysts.A high yield of splitting is achieved when sweet water or glyceryl water is separated from the fat. A good yield can be more than 97% splitting. The raw fatty acids are allowed to evaporate to the atmosphere and the vapour is condensed with cooling. Subsequent to removing the floating fatty matter the water is drained. The fatty acids (CFA) are sent for distillation. The glyceryl water, which may contain about a fifth of glycerine, may be further purified with lime treatment and with filters. This is subsequently used to produce glycerine.

Stainless Steel Storage Tank

25,000 Per Piece

Stainless Steel Storage Tank

Get Price Quote

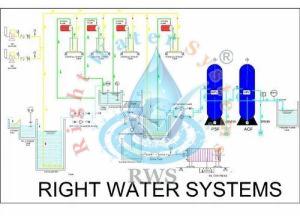

Non Chemical Water Treatment Plant

Get Price Quote

We manufacture and supply a comprehensive assortment of Non Chemical Water Treatment Plant. Non Chemical Water Treatment Plant comes in different sizes and flanges as per the requirements of the customers. Non Chemical Water Treatment Plant supplies water continuously and is eco-friendly. It is low in maintenance, with less power consumption and comes with a warranty of 5 years. Specifications Of SCALE OFF - On Line Scale Prevention System The unit is a non-chemical on-line type scale Preventor not requiring any chemicals. Non-chemical water treatment system prevents the formation of hard scale in cooling circuits of air conditioning equipment. It works with a combination of principles of Adsorption, and Turbulence. The inner core converts the hardness salts into colloidal particles. The unit does not require any electricity or any other source of energy. The unit should not have any recurring, operating and maintenance cost. The size of the unit is determined based on the water quality and water flow rate. The unit is installed in the condenser water circuit. The outer casing is of stainless steel. The company have method of checking the performance of system through computer simulation The unit is backed by 5 year replacement warranty and one year after sales service Selection Procedure : Each model of Scale off works on a defined range of flow rate Each model of Scale off works on a defined range of flow rate In order to select the model flow rate at the tapping of condenser should be known or this can be calculated on the basis of 3-4 USGPM per ton In the table below minimum flow rate is mentioned against each model while maximum flow rate of a model becomes the minimum flow rate of the next higher model Advantages : SCALE OFF possesses many advantages over conventional water treatment systems, some of which include :- As SCALE OFF has no moving parts, it requires no replacement of spares or extra maintenance other than normal plant maintenance. Maintenance Free : As the equipment is installed on – line of the cooling circuit Eliminate Recurring Costs of Expensive Chemicals / Resins : SCALE OFF has no recurring costs associated with chemical dosing or water softening, as no chemicals, regenerative salts or resins are used. No Energy Consumption for running of the equipment : Unlike conventional water treatment SCALE OFF doesn’t require any power or electrical inputs Saves in Energy Consumption of the plant : Scale reduces heat transfer efficiency resulting in increased energy consumption, which can rise by almost 50%. As SCALE OFF is constantly preventing the deposition of Scale, thereby saving valuable energy cost No Corrosion Risk : Water softeners necessitate the use of corrosion inhibitors, as the water tends to be corrosive. SCALE OFF on the other hand has this unique advantage of preventing scale without increasing the risk of corrosion. No Pollution : Chemical dosing and water softening system require the use of chemicals, which are hazardous and cause pollution. Disposal of such hazardous chemicals in the environment is also a difficult task faced by customers. Low Payback Period and Saving of Operational Cost : The pricing of SCALE OFF ensures that the user of the systems derives a payback period of three months to one year. This is made possible by savings in operating cost as compared to the fixed investment required.

Stainless Steel Storage Tank

Get Price Quote

Steam Stripping Column

Get Price Quote

We provide Lube Oil Blending Plant with Automatic Batch Blending (ABB) technology with our state of art software AutoBlend. The full plant can be operated and monitored by touch screen mounted on centralized control panel or web enabled remote device like smartphone or computer. Plant is fully flexible and can accept any numbers of different additives & base oils to make any lube oil. Lubes oil according to standrs of API, JASO, SAE and other well known standards can be made by using our Lube Oil Blending Plant.

Stainless Steel Tank

Get Price Quote

We are offering stainless steel tank. we offer to our clients ms and ss tanks that are available in various shapes and models. These are widely available in various configurations that depend on the functional requirement such as operating temperature and strong medium. The usage of ss tanks is ideal in areas where the storage medium is caustic and less contamination is required. Our range is available as per the specifications stated by the clients at affordable prices. Some of the unique features are as follows: · hygienic · reduces risk of water borne diseases · could be shifted · easy to maintain · eco friendly · competitively priced (50% less expensive than fabricated tanks) · corrosion resistance capacity & gauge in swg: · 50 liters & 16 swg · 100 liters & 16 swg · 200 liters & 16 swg · 300 liters & 16 swg · 500 liters & 16 swg · 650 liters & 16 swg · 750 liters & 16 swg · 1000 liters & 14 swg · 1500 liters & 14 swg · 2000 liters & 12 swg base, 14 swg body · 3000 ltr. & 10 swg base, 12 swg body

Stainless Steel Tank

Get Price Quote

The company is engaged in manufacturing and supplying of Stainless Steel Tank, which is fabricated using the superior quality Steel. Our flawless range of Stainless Steel Tank includes Vertical Cylindrical with Top & Bottom dish ends. This aesthetically designed Stainless Steel Tank is widely installed in industries where there is a need for storage such as Chemical industry, Beverages industry, and so on. Highlights Precisely constructedAccurate dimensionCorrosion resistantCost effective

stainless steel tanks

50,000 Per Pack

We are leading manufacturers and suppliers of Steel Tanks. Specification: Material: Stainless Steel Application: wine fermentation Capacity: Customized Color: Silver Heating method: Electricity Type: Vertical Features: High normative efficiency up to 94% (Hi) 89% (Hs) for the best possible energy utilization. Fully water-jacketed combustion chamber, no sizzling and expansion noises. Full-width boiler door opening to left or right, easy cleaning. Powder-painted casing with supreme finish, easy to assemble. Snug-fitted thermal insulation, 100mm thick, very low radiation losses.

Activated Carbon Plant Machinery

4,500,000 Per Set

1 Set (MOQ)

We are pleased to introduce Piyali Group, situated in Ghaziabad, India. We are leading manufacturer and supplier specializing in the production of Sponge Plant DRI (Direct Reduced Iron) Rotary Kiln & Cooler equipment and vital components for steel plants, alongside catering to a diverse range of industries including sugar mills, cement plants, fertilizer plants, chemical plants, coal washeries, activated carbon plants, and ball mills. With a strong focus on quality and innovation, Piyali Engineering Corporation stands as a trusted provider of cutting-edge solutions across various industrial sectors. With a wide range of offers and a strong customer base, we have been serving the industry for several years. Our product range includes various capacities of DRI kilns and coolers, ranging from 50TPD to 600TPD & 900TPD, along with components such as support rollers, pinions, shafts, shells, combined bearing housing complete assemblies, spring plates, Ball Mill Pinion Shaft, Mill Head End Cover for Ball Mill Manufacturer, girth gears, and more. These offerings are designed to meet the needs of Cement Plants, Power Plants, Steel Plants, Sponge Iron Plants, Chemical Plants, Fertilizer Plants, and various other industries. Explore top-notch Lime Kiln Paper Mill Equipment at Piyali Engineering Corporation for customized, cost-effective solutions. Our commitment to excellence ensures reliable expertise and high-quality equipment, guaranteeing seamless industrial operations. Furthermore, we specialize in delivering high-quality Rotary Kiln & Cooler equipment specifically tailored for 350 TPD and 200 TPD DRI Sponge Iron Plant applications. We specialize in providing all the equipment necessary for your project, including Rotary Kilns and Coolers, ensuring your plant runs smoothly and efficiently. Trust Piyali Engineering Corporation, For superior engineering solutions. With us, you get the perfect fit for your plant's needs, ensuring smooth and efficient operations.

Stainless Steel Storage Tank

Get Price Quote

1 Piece (MOQ)

Stainless Steel Storage Tank

Get Price Quote

We design and supply a wide range of Stainless Steel Storage Tank, which is made from high quality Stainless Steel material. Stainless Steel Storage Tank ensures hygiene and maintains a sterile environment, to keep the product free from microbial contents. The Stainless Steel Storage Tank that we offer is widely used for storing liquid end products before they are packed. Available in different configurations and capacities, this Stainless Steel Storage Tank is durable and incredibly cost effective.Features : Comes with an in-built heating filament with temperature control (optional), Designed using special grade high nickel to avoid corrosion Stainless Steel 304 and 316 used ribbed for high strength and longevity Size 200-5000 ltrs, Comes with inbuilt tank stand weather proof Advantages : Hygienic : Reduces risk of water borne diseases Easy to maintain Eco friendly Competitively priced (50% less expensive than fabricated tanks) Corrosion resistant

carbon dioxide gas plants

Get Price Quote

We are pioneers in bio mass based co2 generation systems. our boiler flue gas recovery plants spin ‘wealth from waste’. co2 from our plants is used by water solution companies for improving the taste of ro purified water. the following paragraphs and attached photographs we introduce international quality plants products we supply at indian prices, an unbeatable combination!!! our plants are made of stainless steel and all critical parts are made of stainless steel 316 grade. We select the very best components. For example all our motors are of siemensabb make. For export we have special 380 volts motors. electrical contacts are of 'siemens' telemechanic make and all our plate heat exchangers are from alfa laval, co2 filling pump is of 'cryo' make, compressors are of 'kirloskar'bockdanfoss dresser rand make. our tank system is with pu insulation fitted with safety valves and with internal refrigeration coil. the entire tank is of special low temperature steel and the entire welding is first x-rayed and then stress relieved, under third party inspection. the tank refrigeration system has the german bitzer compressor and world famous siemens abb motors. refrigeration is fitted with all the controls. Plants from famous european companies are made in mild steel and are still more expensive than our stainless steel plants.the plant comes on skids to minimize time required for installation. we supply storage tanks, tankers and other allied equipments also. our entire plant is warranted against any manufacturing defect for a period of one year. we send our entire team who will erect, install and commission the plant. we are exporting these plants regularly from india. we have installed many units in middle east besides many other countries in the world. our plants produce food grade co2.ours is a iso: 14001-2004 & ohsas 18001-2007 certified company and our website

Stainless Steel Tank

25,000 Per Piece

Stainless steel tank manufacturing capacity 5 ltrs. To 5000 ltrs. As per your requirement complete tank with castor wheel

Mineral Processing Plants

500,000 - 150,000,000 Per Pack

1 Unit (MOQ)

Stainless Steel Tank

Get Price Quote

Our expertise lies in manufacturing and supplying an exclusive range of SS Tank to our precious clients. The offered bins are manufactured by our talented professionals in compliance with the quality standards as per the defined standards. These products are broadly used by catering groups, hotels, hospitals, tent houses, etc. We can also provide these products in customized options as per the detailed specifications of our esteemed clients. Features: • Lustrous shine • Durable • Corrosion resistance

Zinc Plating Plant

Get Price Quote

We are one of trusted suppliers of Zinc Plating that offers solderability, improves corrosion resistance, prevents galling of metal surfaces. Used in varied industries, these zinc plating can be availed in industry standard as well as customized specifications as per the requirement of our clients. We offer these platings at market leading prices. we have gained expertise in offering a wide variety of zinc plating process. Zinc coatings prevent oxidation of the protected metal by forming a barrier and acts as a sacrificial anode. With these attributes this plating is widely used in various industries like textile, automobile and allied. Owing to premium quality, our plating service has received huge appreciation from our valued clients across the globe.

Stainless Steel Storage Tank

300,000 Per Piece

Stainless Steel Tank

Get Price Quote

STAINLESS STEEL TANK - In the manufacturing process of Pharmaceutical and Chemical industries, Heating Process is the prime necessity. So to meet this necessity, our Company R.K. Pharma Machinery offers premium quality range of Stainless steel Tanks. Our offered Tank are made of finest quality of stainless steel, keeping in mind the hygienic standards of the industry. These tanks are specially designed and fabricated as per the industry norms of heat resistance. The quality of our Tanks are highly appreciated by the end users of our products.for high performance, low maintenance, and longer service life. Salient Features of our stainless steel tank are as under: Highly Heat Resistant Premium Quality range of Stainless Steel is used Highly Leak Proof Cost Effective Low Maintenance Longer Service Life

Stainless Steel Tank

750 Per Piece

Chemical Homogenizer Machine

Get Price Quote

stainless steel tanks

Get Price Quote

We design, fabricate and supply a varied range of stainless steel storage tanks made from high quality stainless steel material, our stainless storage tanks are widely used for storing end products before packaging. Ensuring hygiene and maintaining a sterile environment, products in these storage tanks remain free from contamination. available in various configurations and capacities, these stainless steel storage tanks are durable and cost-effective.