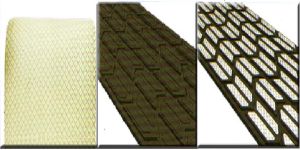

Wavy Top Conveyor Belts

We Offer Wavy Top Conveyor Belts. designed to Handle the Tough Conveying Applications, Ccpl’s Conveyor Belt Series Fulfils the Highest National and International Standards for Tensile Strength and Wear Resistance – Din 22102, Iso 10247 and Bs 490.

...more

Wavy Top Conveyor Belt

Designed to handle the tough conveying applications, our Wavy Top Conveyor Belt fulfils the highest national and international standards for tensile strength and wear resistance properties. Our Wavy Top Conveyor Belt with wavy impression on top is suitable for Loaders and Weigh Feeders. It efficiently conveys powder, granular small lump, paste and liquid materials which scatter easily. International Quality Standards DIN 22102ISO 10247BS 490

...more

Vulcanizing Solution

The reliability of conveyor belt joints, repairs, pulley lagging fixing is dependent on inputs i.e. vulcanizing compounds, expertise and workmanship. Vulcanizing Solution (Insta-Fix) is an instant and reliable ready to use vulcanizing solution for conveyor belt jointing, pulley lagging, repair etc. The INSTACON R & D team has designed and developed INSTA FIX a high peel strength, reliable, instant ready to use jointing/ vulcanizing solution for belt jointing, belt repairing, pulley lagging fixing etc. High targets, tight working schedules, synchronization and interdependence of plants envisage instant solutions to various issues related to the plant maintenance and up keep. Sudden break downs/ stoppages due to damage/ cut/ tear/ joint failure lead to loss of time and production, these being irrecoverable render shear loss in terms of ever lagging targets, dissatisfied customers, loss of incentives, sagging morale of workers etc. The maintenance/ heavy maintenance departments of all continuous/ seasonal bulk conveying/ handling units are always under tremendous pressure to deliver within the minimum possible time, the reliable conveyor belt jointing, repairing, pulley lagging fixing, patch repairing jobs etc, but unreliable and long time consuming (3- 4 Hours) jointing/ vulcanizing solutions available in the market make their job cumbersome and still unreliable Just to accommodate the long curing (vulcanization) time taken by the conventional vulcanizing solutions, it is very difficult for continuous/ seasonal plants to take long shut down and/or to keep the joint area clean for longer period. Benefits of "INSTA FIX" The belt joint, repaired portion can be put to use instantaneously, it is readily available, easy to handle and store. High peel strength. "Insta fix" can be used for jointing, repairing, lagging etc. The chances and fear of jointing area contamination is eliminated as the jointing is instant and no drying or waiting is required. It does not require special procedures. Require normal storage conditions. We are more than positive that after going through the merits of "INSTA FIX" you would like to go for a trial to avail all the benefits offered by "INSTA FIX" to the best of your organizations gain e.g. reliable, instant, easy, clean, jointing/ repairing of the conveyor belts thereby saving precious time and money. On our part, through our other quality products and services, we assure reliable, easy and cost effective material conveying at all times.

...more

Toughflex

extremely High Impact and Puncture Resistance Coversbelt Reinforced with Patented Cross-weaveexcellent Troughabilitylightweightsuitable for the Toughest Heavy-duty Crusher and Demolition Applicationscan Be Vulcanised

...more

Telescopic Jointless Conveyor Belts

This Belt Has Been Highly Acclaimed Especially When They are Used as Telescopic or Feed Belts or Weighing and Packing Belt, It Can Be Driven Over Narrow Pulley Diameter (even Lower Than 100 Mm) At the Speed of 25 Msec designed to Handle the Tough Conveying Applications, Ccpl's Conveyor Belt Series Fulfils the Highest National and International Standards for Tensile Strength and Wear Resistance.

...more

Telescopic Conveyor Belt

Designed to handle the tough conveying applications, our Telescopic Conveyor Belt is widely acclaimed in the market. These Telescopic Jointless Belts are appreciated especially when they are used as telescopic or feed belts or weighing and packing belt, it can be driven over narrow pulley diameter (even lower than 100 mm) at the speed of 25 M/sec. Features Joint, lesser downtimeHigher productivityNo splicing requiredWear resistant High tensile strength Highlight Can be driven over small pulley diameter at the speed of 25 m/sec

...more

Strip Lagging

Strip Lagging is An Effective, Cheap, Convenient and Air Bubble Resistant Pulley Lagging Process Used Globally. ‘instacon’ is a Reputed and Well Established Manufacturer of Strip Lagging in the Country. ‘insta Strip’ Strip Lagging Rubber Sheet is Much Advantageous Than the Conventional Pulley Lagging Rubber Sheets. salient Features of ‘insta Strip’ Strip Lagging Are; minimal No Wastage there is No Minimal Wastage of ‘insta Strip’ Strip Lagging Sheet Material. It is Available in Standard Manageable Maneuverable Size of 200 Mm Width and Continuous Length of 50 Meters or Tailor Made as per Customer Requirements (still Larger Diameter Rolls are Available Subject to Transportable Diameter Weight). conventional Pulley Lagging Sheets are Available in Higher Widths, the Extra Width Pulley Lagging Sheets are Cut to Make Exact Sizes and Excess Portion Left is Often Thrown Discarded Scraped as Wastage, Which is a Sheer Loss to the User Buyer Customer. light Weight ‘insta Strip’ is Light Weight, Handy and Easy to Install. conventional Pulley Lagging Being Bulky, Very Heavy in Weight & Size, Un-manageable Very Difficult to Maneuver Handle and Install, Whether in Roll or Near to Size Form. manageable Maneuverable ‘insta Strip’ Strip Lagging Being Manageable Maneuverable is Easy to Install, Removal of Entrapped Air is Possible, Requiring Less Down Time. conventional Pulley Lagging Being Un-manageable Difficult to Maneuver, Leave Possibility of Air Entrapment Between Pulley and the Lagging Sheet, Which May Lead to Premature Separation Failure of Conventional Pulley Lagging. easy to Repair as the Name Depicts ‘insta Strip’ Strip Lagging is Available in Strips Thus It is Easy to Repair Maintain. Only Damaged Worn Out Portion of the Lagging is Removed and Replaced with Fresh ‘insta Strip’ Leaving Remaining Portion as It is Thereby Saving Huge Cost of Lagging Sheet, Saving On Down Time, Effort Etc. in Case Conventional Pulley Lagging, Complete Sheet is Replaced as Effective Repairs are Not Possible, Which is Very Costly, Time and Effort Consuming Preposition. suitability for Smaller Diameter Pulleys the ‘insta Strip’ Can Be Fitted On Much Smaller Diameter Pulleys Than the Conventional Lagging Sheets. less Inventory since One Type of ‘insta Strip’ Can Be Used for all Types and Sizes of Pulleys this Facilitates Less Inventory Level. a Huge Inventory Level is Required for Conventional Lagging Sheet as Different Sizes Will have Different Inventory Levels. environment Pollution Control our Mission is to Protect Environment from Warming and Toxicity for Our Own and Future Generation’s Sake By Virtue of Providing Energy Efficient Products, Those Render Longer Life. ‘insta Strip’ Strip Lagging Sheet is Available with Special Bonder Rubber. this Feature Facilitates Strip Lagging Application Directly to the Pulley (no Buffing Grinding of ‘insta Strip’ is Required) and Offers Very High Bond Strength Between Pulley and the Strip Lagging. conventional Pulley Lagging Sheets May Not Be Available with Special Bonder Rubber. Rubber Particles and Fumes Generated Flare Up During the Buffing Grinding are Possible Health Hazards and Cause of Concern Worldwide. the Higher Life Offered By ‘insta Strip’ Ultimately Conserves Energy Natural Resources By Avoiding Repeated Manufacturing and Virtually Eliminating Pollution that Would Be Caused Due to Repeatedly Generated Scraps. We Take Utmost Care for Manufacturing, Supply and Service Products. excellent Bonding the Best Feature of ‘insta Strip’ Strip Lagging is that It is Available with ‘insta Fix’ Vulcanizing Solutions, Which Ensures Excellant Bonding Between Lagging and Pulley Due to Absolute Compatibility. the Conventional Pulley Laggings May Not Be Available with Compatible Mother Compounds, Which Leave Scope for Poor Bonding Between Pulley and Lagging Sheet. our Special Designs Not Only Cut On Costs per Ton Material Handled But also Cut Substantial Costs On Power Consumption (an Area, Which Most of the Customers Users Purchasers Over Look Ignore Due to Compulsion of Time, Price, Awareness Etc). pulley Shaft Damage During Removal Transport there’s No Need to Remove Pulley Shaft for ‘insta Strip’ Fixing Hence There is No Fear Chance of Damage or Unbalancing of Both. for Hot Lagging Process Removal of Pulley Shaft from the Installation is a Must. export the ‘insta Strip’ is Exported to Various Countries. to Strengthen Your Confidence Further, We are Enclosing Herewith Sample of ‘insta Strip’ Strip Lagging and Cd Demonstrating Process Procedure of Strip Lagging Fixing for Your Evaluation. we Hope the Above Will Strengthen Your Confidence in ‘insta Strip’ Strip Pulley Lagging and You Would like to have Benefits of It.

...more

Sidewall Conveyor Belt

Our Sidewall Conveyor Belt is widely used in various industries for zero spillage, fast and bulk material handling. Sidewall conveyor belt can be used for horizontal, sloping or vertical conveyance. Our Conveyor Belt with side walls is one of the most effective ways of elevating materials in a confined space. Specialty Single belt operation Handles wide range material No transfer point Low maintenance Big capacity Less space requirement Based In The Following Main Components Cross-stabilized Base Belts Sidewalls Cleats The Base Belt The base belt is designed to bend efficiently in a longitudinal direction and has greater rigidity in a transverse direction by utilizing reinforced fabrics with mono filament that creates a fabric carcass of high tension.

...more

Rubber Conveyor Belts

We Deal in Rubber Conveyor Belts of Premium Quality Which are Used Frequently for Various Industrial Purposes. These are Made from Hi-grade Materials that Ensure High Durability, Tensile Strength, Resistivity to Adverse Conditions, Good Trough-ability and Flexibility. Industrial Conveyor Belts are Suitable for Most of the Application. the Conveyor Belts, We Deal In, are Reliable to the Greatest Extent Due to the Fact that These have a Wide Capacity Range and Very Much Customizable. Moreover, We are Counted among the Major Abrasion Resistant Rubber Conveyor Belt Manufacturers. designed to Handle the Toughest Conveying Applications, Ccpl's Conveyor Belt Series Fulfils the Highest National and International Standards for Tensile Strength and Wear Resistance. routinely Quality Tested in Our In-house Belt Testing Lab, all Ccpl Conveyor Belts are Covered By a 12 Month Manufacturer's Warranty. as An Approved Supplier to Many World Class Customers, You are Assured of the Highest Quality Products and Service. We Monitor all Stages of Our Entire Process with Uncompromising Quality Assurance, from Inquiry Right Through to Delivery-in Accordance with the Stringent Iso 9001 Guidelines. our Ep Multiply Fabric Rubber Conveyor Belts are Designed to Operate in a Wide Range of Industries, for Transporting Abrasive Materials such as Cement, Coal, Granite, Gravel Recycled Material, Iron Ore Grain, Beets, Potatoes, Timber in a Range of Temperatures from -30 C to 90 C (-22 F to 392 F). we Hold Large Stocks of Flat and Chevron Multiply Fabric Carcass Conveyor Belts from 2 Ply to 6 Ply in Various Widths Up to 2400mm (8 Ft), Tensile Strengths and Covers from Heavy Duty Primary to Light Duty Applications, Giving Excellent Cut, Impact and Wear Resistance.

...more

Rubber Conveyor Belt

We are counted among the major Abrasion Resistant Rubber Conveyor Belt Manufacturers. We deal in Rubber Conveyor Belts of premium quality rubber compound with better aging characteristics, which are used frequently for various industrial purposes. These are made from high-grade materials that ensure high durability, tensile strength, resistivity to adverse conditions, good trough-ability and flexibility. The Conveyor Belts we deal in are reliable to the greatest extent due to the fact that these have a wide capacity range and very much customizable. Highlights Standard widths up to 2400 mm in ready stock with both cut or sealed edges as desiredFulfils the highest national and international standardsRoutinely quality tested in our in-house belt testing labCovered by a 12 month manufacturer's warranty Available In Variety of gradesCarcass: Both nylon and polyester fabric (EP)

...more

Rough Top Conveyor Belt

rough Top Belts Designed for Transport of Sacks, Boxes and Parcels. the Top Cover is Made of Wear-resistant Rubber with a Non-slip Surface.

...more

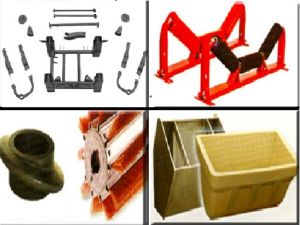

Pulley Lagging, Impact Idlers, Tool Kits, Cleaning Accessories, Elevator Buckets, Skirt Board, Impact Rings, Impact Bars

We Offer Pulley Lagging, Impact Idlers, Tool Kits, Cleaning Accessories, Elevator Buckets, Skirt Board, Impact Rings, Impact Bars Etc. impact Rings impact Rings are Used for Impact Absorption At Loading Points. Ccpl Offers Special Range of Impact Rings and Sleeves Made By Shock Absorbing Rubber Compound impact Bars are Designed to Absorb Impact At the Loading Points of Conveyor Belts, Where a Combination of High Energy Absorption and Low Friction is Needed. Due to Ease of Installation, These Impact Bars the Conventional Idler Sets. impact Bars impact Bars are Designed to Absorb Impact At the Loading Points of Conveyor Belts, Where a Combination of High Energy Absorption and Low Friction is Needed. Due to Ease of Installation, These Impact Bars the Conventional Idler Sets. impact Idlers available Idlers with Impact Rings Made of Special Shock Absorbing Compound belt Cleaning Accessories available Self Cleaning Rings, Strips Brushes, Belt Scrapers and Wiper Systems elevator Bucket available in Fiberpvc, Mild Steel, Stainless Steel for Vertical Material Lifting. skirt Board controls Spilling At Loading Stations, Fits Easily to Existing or New Conveyor System, Consists of Rubber Blocks, Backing Plate, and Serrated Clamps.

...more

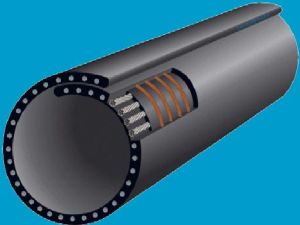

Pipe Conveyor Belts

We Offer Pipe Conveyor Belts. with the Ever Increasing Use of Pipe Conveyors as An Acceptable Form of Bulk Solids Transportation, Especially When Environmental, Operating and Maintenance Costs are of Primary Importance, Has Come the Added Advantage, of Suppliers Breaking New Ground in the Innovation Stakes. features: * Closed Transportation in Order to Prevent Materials from Overflowing, Drop-down, Scattering and Mixing with Foreign Materials from Outside. * this Pipe Conveyor Belt is Economical for Curve(45â°-90â°) and Incline(up to 30â°) Transportation Due

...more

Pipe Conveyor Belt

Designed to handle ecologically dangerous materials that cause severe pollution to the environment and working area, we bring forth Pipe Conveyor Belt for various industrial uses. With the ever increasing use of pipe conveyors as an acceptable form of bulk solids transportation, especially when environmental, operating and maintenance costs are of primary importance, our fine quality Pipe Conveyor Belt is a boon to the industry. Features Closed transportation in order to prevent materials from overflowing, drop-down, scattering and mixing with foreign materials from outside.Economical for curve (45°-90°) and incline (up to 30°) transportation due. Suitable For Iron OreLime PowderCement Powder & ClinkersHazardous ChemicalsHandling grades

...more

Oil Resistant Conveyor Belt

Oil Resistant Conveyor Belts are commonly used for conveying the components & parts coated with machine oil, heavy-oil treated coal in cooking plants & electric power generating plants. These Oil Resistant Conveyor Belts are also used for carrying fish meat and other oily materials containing non-polar organic solvents & fuel. Flawlessly designed as per quality standard DIN 22102, these Oil Resistant Belts are not affected by paraffin oil, naphthalene-based oils, petrol, animal or vegetable fats etc. Our Oil Resistant Conveyor Belts are in line with international quality standards and hence most sought after in the global markets. Attributes Low stretch EP fabricOil and fat resistantCut resistantGood wear resistant propertiesExcellent resistance to damaging effects while conveying oil contaminated or treated materials. Available In (as per cover properties) Anti-abrasive typeOrdinary type

...more

oil resistant

oil and Fat Resistant Coversmedium and Fully Oil Resistant Covers Availableoptional Oil and Heat Resistant Coversgood Wear Resistant Propertiesgood Impact and Cut Resistancemanufactured to Din 22102low Stretch Ep Fabric

...more

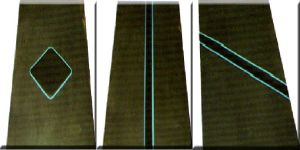

Insta Patch

These Repair Materials are Specials are Specially Designed for Application On Almost all Grades of Conveyor Belts, Except for Hot Material and Food Stuffs Handling Belts. the Patches and Strips are Supplied with a Bonding Layer and in Protective Plastic Films. They are Available Toy You in Diamond, Longitudinal or Rectangular Patches and Strips (with or Without Fabric Insertion with a Bonding Layer and a Special Feather Edge, Enabling the Patch to Merge with the Belt. We Provide Instant Patches as Follows :- * Diamond Patch, * Longitudinal Patch, * Joint Sealing Strip.

...more

Hygienic / Food Grade Belt

Non toxic, Odourless belt used in Sugar Industries, food processing industries and Tea estates etc. rubber compounds used in belts maintain hygiene and product safety.

...more

Hygienic Food Conveyor Belt

Our Hygienic Conveyor Belts and Food Conveyor Belts are fabricated from FDA approved polymers. Our Hygienic Food Conveyor Belts are available in high abrasion resistant, anti-static and oil resistant cover grades. Complying with ISO standards, these food belts are dimensionally accurate and available in standard as well as customized specifications. These hygienic conveyor belts do not stain and odorize the materials to be conveyed and widely used in the food industries for appropriate handling of food stuffs. Our range of hygienic belts is stringently quality checked to ensure that it is free from any kind of defect. Features Anti-static finish for reducing the build-up of dust & dirtOptimum elongationSealed, homogeneous and non-porous surfaceReverse side coating, impregnation of reverse side fabrics and edge sealing for ensuring a completely sealed & hygienic conveyor belt Used In Sugar industryFood processing industryTea estates

...more

Heat Resistant Conveyor Belt

Manufactured with extreme precision using quality methods, our Heat Resistant Conveyor Belt is widely used in various industrial applications. Our Heat Resistant Conveyor Belt is manufactured to DIN 22102. The Heat Proof Belt is widely appreciated and trusted for its efficiency. The Rubber cover protects the fabric of the belt against hot materials such as alumina, ash, granite, iron, copper, grit etc. Attributes Heat resistantCut resistantGood wear resistant propertiesLow stretch EP fabric Specifications Covers Temperatures up to 200°CType "TCC" covers with isolated temperatures up to 400°C Available In Various Grades, Such As Heat Resistant (HR)Super Heat Resistant (SHR)Ultra Heat Resistant (UHR)Heat & Oil Resistant (HOR)

...more

Heat Resistant

Heat resistant coversTemperatures up to 200°CType �TCC� covers with isolated temperatures up to 400°CGood wear resistant propertiesGood impact and cut resistanceManufactured to DIN 22102Low stretch EP fabric

...more

Fire Resistant Conveyor Belt

For underground and surface mining applicationsFor factory and enclosed conveyor systemsFlameproof to ISO/DIN standardsVarious degrees of � re resistance availableAnti-staticGood wear resistant propertiesLow stretch EP fabric

...more

Elevator conveyor belt

CCPL offers special Elevator Conveyor Belts with minimum elongation characteristics. The automated hole punching capabilities provide precise bucket and row spacing, clean tight-fitting bolt holes, and quick delivery. Elevator belts can readily meet all OEM specifications, including heavy duty black belts, solid woven PVC belts; oil resistant belts; and high temperature belts (rated up to 400°F). Elevator buckets may also be purchased separately (unattached) in large or small quantities. These Elevator Conveyor Belts are suitable for vertical transport of materials. Highlights Speeds and flight pitches are specified to suit the product throughoutAngles of up to 80 degrees can be achievedThese belts can be fitted with or without side skirtsWidths from 100mm up to 1 meter and lengths from 1 meter to 12 meters can be supplied on one drive making it a cost effective choiceOptional in-feed hoppers and chutes are availableCan be supplied for high or very low temperatures Available In Material Such As Modular BeltsPlastic BeltsPU Belts Applications Raw food packagingBread packagingCanningBottlingGeneral packaging Available Grades IPM-24HRSHRHOR Attributes Oil ResistantWhite/Hygienic Food Grade

...more

Elevator Belt

these Belts are Suitable for Vertical Transport of Materials. Ccpl Offers Special elevator Belts with Minimum Elongation Characteristics; Available in Various Grades, Ipm-24, Hr, Shr, Hor, Oil Resistant and White/hygenic Food Grade.

...more

Maintenance Services

We are renowned among the most dependable providers, Maintenance Services in India. Our team of experts has an in-depth knowledge of the various aspects of Repairing and Maintenance of various industrial conveyors. They keep themselves abreast with the latest trends in the market so that they can cater to the specific demands of the clients. Our Repair & Maintenance Services have been availed by various leading industries. Our team comprises of civil engineers, technocrats and others who have give new dimensions to Cleaning And Maintenance Services. All of these services can be availed at minimal charges and within stipulated time frame. Our full range of vulcanising skills combined with our conveyor experience mean we can deliver inspection reports, conveyor safety audits and practical preventative maintenance. The Conveyor belt can be rendered endless through vulcanising or by use of fasteners, Join being weakest point of the belt requires deligent and meticulous craftspersonship. Our techincians equipped with latest know-how and best vulcanising material; backed by our state-of-the-art machinery would provide you the following services for a nominal charge * Vulcanising (Making endless) Conveyor Belt of any specification and any width(On site or at our factory) * Pulley Lagging * Repair Patches * Annual Maintenance Contract for providing above mentioned services on site whenever required

...more

Belt Conveyor Maintenance

We are renowned among the most dependable providers Belt Conveyor Maintenance Services in India. Our team of experts has an in-depth knowledge of the various aspects of Repairing and Maintenance of various industrial belt conveyors. They keep themselves abreast with the latest trends in the market so that they can cater to the specific demands of the clients. Our Repair & Maintenance Services have been availed by various leading industries. Our team comprises of civil engineers, technocrats and others who have give new dimensions to Cleaning And Maintenance Services. All of these services can be availed at minimal charges and within stipulated time frame.

...moreBe first to Rate

Rate ThisOpening Hours