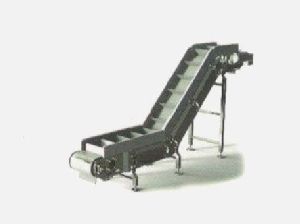

Skip Conveyor

Get Price Quote

Gluing Machine with Conveyor

Get Price Quote

1 Piece (MOQ)

"Memory" Gluing Machine with Conveyor is designed for short & medium run jobs. The Gluing Machine consists of: Sturdy Aluminum profile structure with suction hold conveyor belt to ensure high quality boxes. Specially designed gluing system for top side gluing suitable for Hot melt & Cold glue application. CNC cylindrically grinded roller ensures even glue application on all cover materials. Optional : Pressing Station with twin set of Silicon Rollers for sheet to sheet pasting jobs.

Best Deals from Conveyors

Industrial Oven

Get Price Quote

Vacuum Oven

Get Price Quote

Product Description : Designed for desiccation, vacuum embedding, plating, process control, and inert atmosphere applications. Radiant warm wall heaters mounted outside of chamber to conserve chamber-working space and eliminate the hazards of open wire heaters. 3 (7.6 cm) glass wool insulation minimizes heat loss from chamber. Two piece stainless steel shelf systems improve heat conduction to samples and are easily removed for cleaning. Corrosion-resistant # 304 stainless steel interior. Tempered glass window in door allows viewing of samples. Vacuum and air lines constructed with corrosion-resistant stainless steel tubing for optimum chamber cleanliness and long term performance. Durable powder coated heavy gauge steel exterior. It is available in 3 shapes ( circular , square , rectangular ) Operation : Digital Temperature Controller controls temperature from ambient +5°C to 200°C. Glass thermometer in working chamber displays actual temperature. Precise vacuum control to 30 (76.2 cm) Hg displayed on analog gauge. Secure door latch and continuous Silicon gaskets on vacuum chamber provide a tight seal and maintain a vacuum leak rate of less than 1 Hg per 24-hour period. Vacuum control and relief valves located on front of unit for convenient monitoring.

Truck Loading Conveyor

Get Price Quote

flat transmission egg collection belt

40 - 45 Per Meter

10000 meter (MOQ)

Heavy Duty Industrial Oven

Get Price Quote

We are offering updated bench models of High Temperature Industrial Oven. Our heavy duty High Temperature Industrial Oven is widely used for research laboratories and production departments. It is ideal for most sterilizing, aging, drying, curing, electronics burn-in, conditioning and life testing and temperature applications. It is solid state temperature controlled oven where the ultimate accuracy is required.Detail Chamber : Double Walled Exterior Chamber : Exterior Chamber is made of heavy duty mild steel, treated for rust prevention and given a long-lasting baked enamel finish. Interior Chamber : Interior Chamber is rugged and made of heavy duty long lasting stainless steel. Insulation : Pre-Compressed 3” thick glass wool insulation surrounds entire chamber which prevents ‘settling’ and possible heat loss and is impervious to corrosive fumes and vapors. Homogeneous Circulation : Heavy Duty Air Circulation Fans provide homogeneous air circulation throughout the entire chamber. Door : Double Walled full front opening door, exterior wall of mild steel and interior of stainless steel and insulated with pre-compressed glass wool. Hinges & Latches : The door is also provided with heavy duty hinges with toggle type locking arrangement. Heating Elements : Efficient Nickel Chromium coils wound on porcelain refractories maintain low surface temperature even while operating at highest range settings. Over-Temperature Protection : Automatic Over-Temperature Thermostat protects against excessive temperature and damage. The thermostat is independently circuited and is adjustable for high temperature protection at any point in the operating range. Heating Elements : Will be placed on both side Temperature Range : 50oC to 500oC Controller : Digital Temperature Controller-cum-Indicator Accuracy : ± 3oC Controller : Digital PID Temperature Controller-cum-Indicator Accuracy : ± 2oC Controller : Microprocessor Based Programmable Controller with Printing Facility Accuracy : ± 1oC Shelves : No of quantity depends on size

Steel Rollers

Get Price Quote

We manufacture a wide variety of Rollers for Steel Industry. Using Ultra-modern & latest machinery, we manufacture rubberized Rollers for Cold Rolled Steel & Continuous Galvanizing Line. We are the largest suppliers of rubber coated rollers to Jindal, Hissar produced at our Unit in Neemrana, Rajasthan. We are producing very specialized rollers for steel industry and supplying to JINDAL HISSAR. As per our best knowledge there is no other company which provides such critical application rollers in north India. After being satisfied with the performance of our rollers which were supplied to these customers we have decided to enter other steel industries located in different part of the country who require high quality products.

Bakery Oven

Get Price Quote

Feeding and Stacking InkJet Conveyor

Get Price Quote

Product Code : FSIC Feeding & Stacking InkJet Conveyor is one of the best equipment designed and fabricated by Shri Vinayak Packaging Machine Pvt. Ltd. This specific equipment is regarded as an exceptionally versatile conveyor, whose functions are similar to that of standard Stacking InkJet Conveyor, but it has several additional features which makes it a most professional and efficient machinery. Its unique design allows simple and quick cleaning for smooth operation. Its speed can be adjusted and additional option can be provided for operating in reverse direction. Since inception, the company has been carving strong excellence marks in the industry. Supported by expertise and know-how of professionals in the field of manufacturing material handling equipment, we have been catering to needs of many small and large companies across multiple industrial sectors; consequently attaining a leadership position in this competitive market. We use stainless steel and other material to construct these Feeding InkJet Conveyors. Its rugged constructed bestows it with the ability to perform in all environments with highest efficiency possible.

Belt Conveyor

Get Price Quote

Belt Conveyors are common today and widely used to transfer the material constantly in a straight, horizontal or inclined path. India SKS is specialized in designing and manufacturing a wide range of Conveyor belts for various uses. We as a belt conveyor manufacturer offer you the most effective bulk handling conveyors that can be used for transferring items. Our products are known for reliability, flexibility and range of capacities. We specialize in supplying belt conveyor in different shapes, styles and designs. Belt conveyors contain two pulleys at both sides of conveyor with support idlers below makes belt rotates forward. We use a variety of belt materials containing lattice, strip and chain, to meet the exact design for your needs for. There are two industrial kinds of belt conveyors – one is material handling for example moving boxes in a factory and other is bulk material handling for example transferring large quantity of materials - sand, grain, salt, etc. Today, conveyor belts are manufactured for transferring different kinds of materials. Leading manufacturer of conveyor belt in India Conveyor belt for sell is well-examined and therefore, is the best choice on which purchasers can easily depend. India SKS is considered as one of the best manufacturers and suppliers of conveyor belt in India. We produce the conveyor using quality material and superior techniques at our well-resourced production place. We also perform strict quality tests on every product so as to make sure that only the fault free equipment reaches to your side.

Conveyor Belt

Get Price Quote

The machine is suitable for conveying all kinds of panel working line. The conveyor is adjusted by inverter with stable and uniform The conveyor is imported PU belt (optional :stainless steel net belt or roller)

Rollers For Steel Industry

Get Price Quote

We manufacture a wide variety of Rollers for Steel Industry. Using Ultra-modern & latest machinery, we manufacture rubberized Rollers for Cold Rolled Steel & Continuous Galvanizing Line. We are the largest suppliers of rubber coated rollers to Jindal, Hissar produced at our Unit in Neemrana, Rajasthan. We are producing very specialized rollers for steel industry and supplying to JINDAL HISSAR. As per our best knowledge there is no other company which provides such critical application rollers in north India. After being satisfied with the performance of our rollers which were supplied to these customers we have decided to enter other steel industries located in different part of the country who require high quality products. The Steel Rollers manufactured by us has the following USP:- Have developed compound for high speed to heavy load application. We manufacture Rollers exactly as per sample, specification and drawings provided. All operation of Roller manufacturing is done in one Roof thereby ensuring Quality control and timely delivery. Capable of manufacturing Roller upto Dia 1.6 mtr Length 8 mtr and weight 30 tons. Our Roller coverings are designed to offer increased service life, fewer roller changes and minimal maintenance when compared to other alternatives. We are manufacturers of high quality rubber roller mainly for critical application and use different types of polymer like HYPALONE, VITON, NBR, HNBR, NBR PVC, CSM (NEOPRENE), NATURAL AND SILICON. Zenith Rolls undergo from more than 25 quality testing Equipments as per requirement. ( For detail refer to Our Product >> Compound) Services we offer New core design & fabrication Rubber Covering Crowning Grooving Regringing Core Repair Ultrasonic test & Balancing Engineering service Extensive Support pacity We have manufactured roller upto following sizes : Length : 8000mm Dia : 2000mm Weight : Upto 30 tonne We manufacture more than 100 new rollers per month. And the Roller size accuracy upto 5 microns is maintained. Shore hardness of Rubber & run out standards are properly adhered to for each & every roller.

Conveyor Ovens

Get Price Quote

We are know as one of the main manufacturers of Conveyor Oven. The conveyor oven is widely used where continuous drying bakingheating or curing of the items is required.

Lubrication system

Get Price Quote

Hi - we are india's largest distributor of lubricants (online+offline). We sell lubricants for castrol, crc, mak, rust-oleum etc

Roller Conveyor

Get Price Quote

Non Stick Curing Oven

Get Price Quote

We make sure that the packing of our products is done using quality materials and advanced machines. Our packaging experts handle the entire task of packaging keeping in mind the requirements of the clients. Our clients can rest assured for the safety of their financial details, along with quickness in payment processing.

nylon idler

3,500 Per Piece

1 Piece (MOQ)

Industrial Oven

185,000 Per Piece

1 Piece (MOQ)

Belt Conveyors

Get Price Quote

In the wake of ever-rising demand for reliable products, we are engaged in offering a wide assortment of Belt Conveyors. Belt Conveyors are manufactured by using first grade raw material that is sourced from reliable vendors of the industry. Belt Conveyors are widely demanded by customers for their high durability, superior quality, compact size, easy installation, and optimum performance. Technical Details : Material : MS, SS and Aluminium. Adjustment : In height and inclination Type : Angular and Straight both. Transmission Type : Both Roller Based and motorized(with variable speed) Belt Used : Rubber, Poly-urethane etc. Payment Terms : T/T or Wire Transfer

Vibrating Conveyor Motor

Get Price Quote

Our payment procedures are well documented, legal, and safe. We provide our clients with numerous online and offline options for making purchases and make sure they are protected. Our organization is a well-known name in New Delhi(India), reputed for supplying the finest range of the product at the lowest prices.

High Temperature Oven

Get Price Quote

High temperature Ovens is triple walled oven. Inside chamber of stainless steel and outer chamber develop using high grade mild steel with powder coated finish. This coating keeps safe the unit from rust and normal scratches. Temperature ranges from 50°C to 300°C with temperature accuracy of ± 3°C. The temperature is totally microprocessor based P.I.D. or Digital Temperature Controller Cum Indicator controlled for accurate temperature rating. The High temperature Ovens comes in various sizes and capacities such from 45 liters to 1037 liters. Triple walled Inner Body: Inner chamber made of Stainless steel. Outer Body: outer chamber develop using high grade mild steel with powder coated finish. This coating keeps safe the unit from rust and normal scratches. Insulation between inner & outer wall with glass wool/ mineral wool thick to avoid any heat loss. Temperature Range: Temperature ranges from 50°C to 300°C with temperature accuracy of ± 3°C. Temperature Controller: The Temperature is totally microprocessor based P.I.D. or Digital Temperature Controller cum Indicator controlled for accurate temperature rating. Air Circulation :Forced convection system through use of blowers & motors that provides for superior mixing as well as strong dispersion Power: Power input to be 220-230 Volts AC, 50/60 Hz fitted with Indian plug. Safety Feature: Thermostat based safety device. Shelves: Stainless steel perforated/wire road shelves adjustable and sliding.

High Temperature Oven

Get Price Quote

High Temperature Oven (300°C) Triple walled, inside mild Steel / Stainless Steel and outside made of Mild Steel painted in epoxy Powder Coating. Temperature range 50 °C to 300 ° C plus minus 3 ° C with Digital Indicator Cum Controller . Heating Elements are placed on both sides. Complete with 2/3 nos removable S/S Wire Mesh. One no. Air Circulating Fan, on/off switch to work on 220/230 or 400/440 volts 50 Hz A.C. Option:Microprocessed PID controller having 4 ramp & 4 soak profile having set mode, alarm parameter, configuration parameter, profile parameter, set point profile, Pv error indicator , parameter for locking etc. Alarm:It is possible to provide electronic alarm, if temperature deviates more than ± 5 °C to cost extra

Aluminium Belt Conveyor

Get Price Quote

We are a quality-conscious firm and make sure that our offerings are prepared using the world-class raw material and work methods. Also, the material is sourced from the trusted places only. To ensure utmost satisfaction of the buyers, we make sure that the delivery schedule should be properly maintained.The offered Aluminium Belt Conveyor works with a speed of 30m/min.

Gas Purification System

10,500 - 30,000 Per Piece

We are engaged in offering durable Gas Purification System, specially sourced from the reliable vendors of the market ensuring high performance and optimum utility. The Gas Purification System, offered by us, is compact in design, wall mounted and powder coated. The Filters of Gas Purification System are easily detachable and easy to install. Our Gas Purification System is very effective and helps delivering ultra high pure (UHP) grade gases. Avail our Gas Purification System at competitive prices. Features : Deliver ultra high pure (UHP) grade gases Compact design, wall mounted, powder coated Filters are easily detachable Suitable for 10 kg/cm2 Inlet pressure and 7 kg/cm2 outlet pressure Panel for Gas Chromatograph, LC-MS & LC-MS-MS are available

Ms Gravity Roller Conveyor

200,000 Per Piece

Stainless Steel Rolling shutter

Get Price Quote

Attachment Chains

Get Price Quote

Pizza Ovens

Get Price Quote

We are offering pizza oven.

Roller Conveyor System

40,000 - 500,000 Per Set

1 Set (MOQ)