Corrosion Test Chamber

Get Price Quote

Salt Spray Corrosion Test Chamber

Get Price Quote

Touch Tone Salt Spray Fog Tester is used to test the corrosive resistance of products whose the surface was treated with paint, electroplating, inorganic and organic film, anode handling, anti-rust oil.

Best Deals from Corrosion Test Chamber

Salt Spray Corrosion Test Chamber

Get Price Quote

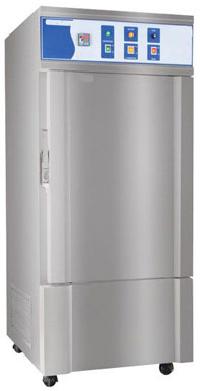

Corrosion Test MASTER i9Junior (Touch Panel, Digital)

100 - 200 Per 1 Piece

1 Piece (MOQ)

Corrosion tester is the most reliable equipment for checking the corrosion resistance of surface coatings when exposed to a salt laden environment. This time-tested product has been specifically designed to assess the rust-proof ability of components to withstand corrosion due to atmospheric conditions. It provides complete flexibility in simulation of real life weathering conditions. The device is used in industrial testing laboratories for various research and analysis purposes. The instrument is capable of creating very high temperatures for testing and studying the effect on different painted and plated metal substrates. Paramount Corrosion Test Master Junior i9™ is a Next Generation Equipment with a Touch Panel control to perform accurate testing. T he test temperature in the chamber is user adjustable from ambient to 40 °C and is controlled by a PLC controlled Touch Panel HMI Unit. The touch screen is a powerful tool that eases the analysis of corrosion resistance for a wide variety of sample types. A special zero corrosion RTD sensor is incorporated in the Equipment for Accurate & Reliable results.

cyclic corrosion test chamber

Get Price Quote

Corrosion Test Chamber

Get Price Quote

Whether you are new to corrosion atmosphere testing or have been conducting testing for years, we present Salt spray chambers or Salt Fog Chambers that are not only easy to use and maintain but also provide the accuracy and flexibility necessary to meet today's demanding corrosion test procedures including Salt Spray Test, Condensation Water Test and Cyclic Corrosion Test. These machines create three types of manually adjusted environment; salt spray, high humidity and air drying at any given temperature within the chamber. Any combination of these environments can be programmed, in any order, to form a corrosion cycle. Such a corrosion cycle can be automatically repeated a predetermined number of times. Our models meet the requirements of basic, continuous salt spray tests conducted at a single temperature only, such as ASTM B117 and similar international test standards, and may be used with pH neutral salt solutions (NSS) or those acidified by the addition of Acetic Acid (ASS), Seawater Acidified Test (SWAAT) or Cupric Acid (CASS). Models above 480 Liters of capacity are ideal for Cyclic Corrosion Cabinet (Cyclic Corrosion Chamber). In Laboratories corrosion tests are used extensively for selection of materials and their surface protection. Our Corrosion box chambers are what you need to predict corrosion resistance of materials such as paints and coatings and are designed and developed to meet the widest possible range of industry standards: • Salt fog testing as specified in DIN 50021 • Condensed water test as specified in DIN 50017 and EN ISO 6988 • Standard climates as specified by DIN 50015

Salt Spray Chamber, Corrosion Test Apparatus

Get Price Quote

Backed by a team of expert professional associates, who are having years of experience in the domain, we are rendering salt spray chamber or corrosion test apparatus. The offered product-line finds it used in different industrial applications and are widely acclaimed for its reliability and durability. Apart from this, the offered range is offered at the most market-leading price. features: digital indicators cum controller/indicator digital timer (999 hours) humidity meter with sensor mist dispersion automizer drainage system heating system hanging provision/rack provision air regulator air filter fog collection unit

Corrosion Test Chamber

Get Price Quote

The Sulphur Dioxide Test Chambers from Weiber are Corrosion Test Chambers used for testing the corrosion resistance of metallic surfaces and outer protective layer of coatings. They are used to create a highly corrosive environment rich in corrosive gases and natural humid conditions to induce accelerated corrosion in protective coatings of machines and equipments, electrical items, electronic parts and components, mechanical constructions, automobile and aircraft parts and components etc. Since the corrosive action of Sulphur dioxide also depends on specific temperature and humidity conditions and the presence of other contaminants, the Weiber Sulphur Dioxide Test Chambers are designed to create optimal conditions of temperature and humidity and also make provisions for introducing impurities and contaminants. These equipments operate across a wide temperature range, creating variations in the working temperature to mimic a natural weathering environment. The SO2 Test Chambers from Weiber are designed in accordance with international standards and can be completely customized according to specific requirements. They use advanced and sophisticated technology to ensure safe and reliable operation and are easy to use and maintain. These equipments are available in visually appealing aesthetic designs and find widespread usage in industrial manufacturing units and research organizations. They are designed for diverse and versatile applications and often function as fog test chambers and automobile accelerated corrosion test chambers.

Corrosion Test Chamber

Get Price Quote

Corrosion Test Chamber, Hardness Software, Abrasive Cut Off Wheels