Sym Cut 7000

Get Price Quote

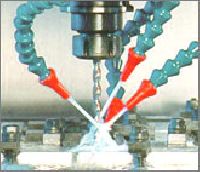

Cut 7000 Strong is a clear dark green semi-synthetic cutting fluid. It maintains a constant PH value for a long period of time. It assures uniform concentrated oil drops on the cutting tools, that ensures high quality finishing on the component being worked on. It has enhanced performance characteristics. It can be used on all cutting tool materials namely HSS coated / unquoted, Tungsten coated / unquoted PCD ceramic etc. It can be used for all ferrous and non-ferrous alloys.General Application Sawing Boring Drilling Milling Turning Tapping Facing Attributes Good Corrosion Protection Good Detergency High workpiece visibility Long Fluid Life High Thermal Stability

Grinding Fluids

90 - 250 Per Litre

50 Litre (MOQ)

Grinding: We understand that grinding fluids are crucial in the grinding process. Not only are they needed to reduce friction, but also for their ability to extract heat from the work zone and maximize material removal. This is why are grinding fluids are formulated with advanced polymers, corrosion inhibitors and powerful detergents that result in superior quality surface finishes. Our technology is developed for use in OD/ID, Blanchard, surface, internal, form and cylindrical grinding applications. All of the products are compatible with diamond, CBN, vitrified and resin-bond wheels. The products are formulated from high-purity, natural petroleum and synthetic base stocks. They are job specific and are available in a range of viscosities that will complement any filter system.A. MineralThese fluids are low-viscosity, low-smoke grinding oils using special additives for effective grinding of high nickel alloys, tool steel alloys and carbide. These products provide excellent heat transfer coupled with high lubricity that help eliminate tool micro-structure damage and surface discoloration. These products are non-toxic and non-irritating to machine operators. It is not corrosive to steel, carbide or non-ferrous alloys. High lubricity, excellent wetting and extreme pressure properties help extend grinding wheel life, maintain wheel form and minimize burning. B. SyntheticOur synthetic fluids are very low-viscosity, low-smoke synthetic grinding oils for tool steel and carbide respectively. These products are blends of special additives in synthetic oil for increased lubricity and burn-free performance at elevated temperatures. Both products are formulated with an additive package that will not be stripped by diatomaceous earth filter systems or quickly depleted during use.C. Semi-SyntheticThese fluids are blends of synthetic hydrocarbon, synthetic ester and highly refined mineral oil. These are low-viscosity, low-smoke grinding oils that exhibit high lubricity at a reduced viscosity to maximize heat transfer for excellent grinding performance.

Best Deals from Cutting Fluid

Pal Grindol-40 Synthetic Cutting Fluid

150 Per Litre

PAL GRINDOL-40 It is a premium quality of synthetic type of coolant which is water soluble developed for griding operations only for ferrous metals. The solution formed is fully clear, alkaline in character and has good anti rust properties. It is non foaming, non-toxic & non-hazardous. Due to adequate concentration of bactericide, it does not undergo bacterial degration & leave bad odour. It is operation friendly & economical to use. PAL GRINDOL-40 is fortified with rust, corrosion, inhibitor, lubricity agents & bactericide, fungicide. Recommended for griding operations on ferrous metals & alloys only & not recommended to non-ferrous metals. Dilution ratio in 3% gives excellent grinding with smooth surface finish. Concentrated mixture can lead to peeling of the paint on the machines & some discoloring of the opearator's skin

Metal Cutting Fluid

115 Per Litre

210 Litre (MOQ)

Z Premium Metal Cutting Fluid,The two main tasks of cutting fluid are cooling and lubricating. ... As well as cooling machinery, cutting fluids also help metalworking processes by lubricating the area between the cutting edge of a tool and the chip

Metal Cutting Fluid

Get Price Quote

We share glorious credentials in the list of top Manufacturers, Exporters and Suppliers of Metal Cutting Fluid from Delhi, India. The formulation of our Metal Cutting Fluid is based on a blend of paraffinic mineral base oils plus suitable additives. When it comes to delivering Metal Cutting Fluid, we use fast shipment modes so as to ensure its prompt and timely delivery at the customers’ end. Applications : As an emulsion lubricant and coolant suitable for application in most type of machining and metal working operations. Advantages : Mixed readily with water to form stable emulsions Good rust preventive and anti-foam properties Formulated to effectively remove heat from metalworking operation Emulsion resistant to freezing and additive separation Protection against bacterial growth and deterioration Low- staining characteristics Preparation : Soluble oils are prepared for use by mixing them with relatively large portions of water. The oils must always be added to the water. Never add the water to the oil. Usually one part oil is stirred into four parts water. Adding water to this mixture then makes the desired dilution. Oil should never be added directly to the existing emulsion. For best emulsion stability, rust and bacterial growth protection, low hardness water should be used to prepare emulsions. It is important that the correct oil-water proportions be maintained in service.Evaporation in the water, which is espacially rapid inmachining operations that developed high temperatures, may enrich the emulsion excessively. Conversely, finely divided prticles carried away by the emulsion may, when filtered out, remove more oil form the emulsion than water and thus make the emulsion leaner. Oil concentration should be checked at any time. With the oil separated from the water, its concentration can easily be observed and corrected as necessary by adding an emulsion with definite concentration. Avoid strong suitable oils below freezing temperatures. If freezing should occur, re-warm to room temperature and mix product well before using.

Environment Friendly Soluble Cutting Fluids

Get Price Quote

We are one of the trusted names in industry, engaged in manufacturing, supplying and exporting a wide range of Environment Friendly Soluble Cutting Fluids. These fluids are processed using top quality chemicals and upgraded technologies. Besides this, our range of these fluids is made in compliance with industrial standards. Effective results, easy spreading and enhanced properties are the features of these fluids, which make them widely praised among the clients. Features: Reliable Easy to use Longer shelf life Other InformationMinimum Order Quantity: 100 Litre

Metal Cutting Fluids

Get Price Quote

These cutting oils are more commonly referred to as soluble oils. This however, is a misnomer because they are not really soluble in water but form an emulsion when added to water. These emulsifiable oils are mineral oil based concentrates, which contain emulsifiers that allow them to mix with water and form a milky white emulsion. They also contain additives to improve their lubricating properties, rust and corrosion inhibitors and a biocide to help control foul smell.

Metal Cutting Fluids

Get Price Quote

Metal Cutting Fluids, Hydraulic Oils, silicone oils, Gear Oils

Metal Cutting Fluids

Get Price Quote

Metal Cutting Fluids, Lubricating Oils, hydraulic fluids