Oxygen Plant

Oxygen plant, oxygen gas plants equipped with the state of the art features. The plants are employed with the latest European technology helping us not only producing economical plants, but also the machines that require low upkeep, maintenance cost and high performance. To generate oxygen and nitrogen gases, our plants take the air from an air compressor and separate the oxygen and nitrogen from other gases. Come up with different capacities ranging from 20 m3hr to 5000 m3hr, the oxygen gas producing plant produce 99.7% pure oxygen and nitrogen as a second product with purity upto 99.99%.

...more

oxygen nitrogen gas plant

We have successfully risen as a leading manufacturer and exporter of oxygen nitrogen gas plants. The company acquires technology along with components from international companies. The technology inserted in our products is appreciated all over the world, and has been considered as the best in terms of efficiency, functionality and trouble free operation. Our plants fabricate oxygen and nitrogen from atmospheric air from the process of rectification/distillation. DCPL manufactures and exports the oxygen nitrogen gas plants in small, medium and large capacity. Employed in a number of industries such as water process, ferrous metallurgy, non-ferrous metal refinery, coal mines and pharmacy, our plants can be availed at industry leading prices. A variety of plants fabricated by our company is highly appreciated for a number of features such as low maintenance cost, sturdy construction, high efficiency and longevity features. Furthermore, our products can be easily tailored as per the requirement, specifications and details of our customers. Salient Features: Liquid tapping Almost zero maintenance 100% leak proof stainless steel No special civil foundation required Latest technology Come up with liquid oxygen pump

...more

oxygen gas plant

We are a leading manufacturer and supplier of oxygen gas plant at our well equipped facility. It fills in compressed oxygen into cylinders at standard 150 to 160 Bar (kg/cm2). The purity of the output is upto 99.7%, which is perfect for healthcare and industrial applications. The systems get acclaimed for a number of features such as advance technology, low power consumption, skid mounted technology, ease of installation and minimal maintenance. Oxygen plant model 50 m3/hr is designed and manufactured to generate compressed oxygen gas in cylinders with purity upto 99.7% and at standard 150 to 160 Bar (kg/cm2). The system produces high purity industrial and medical oxygen. The model dcpl 50 use liquid oxygen pump technology to fill liquid oxygen directly from the liquid in the condenser to fill compressed gaseous oxygen in cylinders at 155 bar( 200 bar optional). SALIENT FEATURES : SKID MOUNTED DESIGNS: Due to the design, all our equipments and machineries are mounted on single skid ready for installation. AIR SEPARATION UNIT (COLUMN): The columns are made from cryogenic grade STAINLESS STEEL materials with argon welding in order to make them leak proof operation and to produce high quality medical and industrial oxygen . LIQUID OXYGEN PUMP: Oil-free and water free design with special stainless steel head, the pump fills in compressed gaseous oxygen in cylinders. MOLECULAR SIEVE BATTERY: We use special over-size design with L/D ratio to prevent fluidization and long life with molecular sieves of Zeochem, Switzerland/ceca france . PURITY: 99.7 % High purity of Oxygen for medical and industrial uses. PROCESS SKID: All equipments are mounted on processed skid complete with gas/air/ water lines for high purification of air. TECHNOLOGY: Our technology is internationally approved for its exceptional performance, durability and usefulness.

...more

Molecular Sieve Battery

Molecular Sieve Battery/Dryer Consisting Of 2 Cylindrical Vessels With Stand And Base Fitted On The Skid. It Consists Of Two Vessels A And B Working Alternatively And Filled With High Quality Molecular Sieve (Probably Zeochem, Switzerland Brand).

...more

liquid oxygen pump

A Horizontal Single Acting Pump W/ Stainless Steel Piston And Special Graphite Impregnated Teflon Piston Ring For Long Life Working Inside For Filling Oxygen Directly At The Pressure Of 150 To 200 Bar At Cylinders.

...more

liquid oxygen plants

DCPL is a reputed and known company in the industry for manufacturing, developing and supplying a wide range of liquid oxygen plants. The plants perform in compliance with North American and European Pharmacopoeia standards. Available in a number of sizes from 50 m³hr (70 literhour) to 500 m3hr (700 litershour) capacity, the liquid oxygen plant is highly safe, effective & efficient to operate and perfectly fulfill the application requirements of our clients.

...more

Liquid Oxygen Plant

DCPL is a reputed and known company in the industry for manufacturing, developing and supplying a wide range of liquid oxygen plants. The plants perform in compliance with North American and European Pharmacopoeia standards. Available in a number of sizes from 50 m³/hr (70 liter/hour) to 500 m3/hr (700 liters/hour) capacity, the liquid oxygen plant is highly safe, effective & efficient to operate and perfectly fulfill the application requirements of our clients. Our company designs and develops a wide range of liquid oxygen plants for directly filling liquid into tanks. They are made in technical collaboration with internationally approved companies. Since our establishment in 1987, we have been serving a long list of satisfied customers located different parts of the world. Despite of technology and components, our customer service is also unmatched in the industry. The products are recognized globally for being highly reliable, effective and efficient. Compression of Air: Our company supplies advanced air compressors taken from the international market to compress the atmospheric air. Thereafter; the air is sent for purification. Purification of Air:The compressed air comprises of impurities like CO2 and moisture. These impurities get removed in the process before cooling. Cooling of Air: The purified air needs to be cooled down to temperature about 15 to 20 degree centigrade. Thereafter; it becomes ready to separation. Separation of Air: The cool and purified air reaches to the process where air gets separated before being filled in tanks. Filling Tanks/Bottles: It is the last step, where the liquid nitrogen gets filled in tanks and bottles and distributed to end users.

...more

Liquid Oxygen Nitrogen Plant

Established in the year 1987 in NCR region of New Delhi (India), we are a manufacturer and supplier of different capacity oxygen nitrogen plants, oxygen plant, air separation plants, acetylene plants from superior quality raw materials and internationally approved components. Each raw material and component employed is acquired from reliable and trustworthy vendors. With the technologically advanced & well equipped manufacturing facilities and experienced manpower, we become able to design and manufacture the oxygen plant which are technologically very advanced and acclaimed for their low capital & running cost, longer operational life, excellent production capacity, least power consumption, ease of installation and so on features.

...more

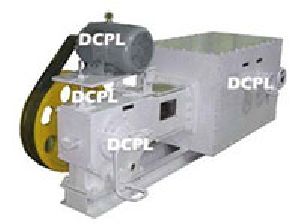

Expansion Engine (expander)

Expansion Engine With Hydraulic Valve Control, Bursting Disc For Safety, Fly Wheel Pressure Gauge, Motor Pulley V-Belt, Belt Guard, Slide Rails Inter Connected Pipes (Inlet & Outlet) Hydraulically Operated High Efficiency Engine With Ball Type Of Valve Stainless Steel Liner Vertical Type Of German Design. Complete With Motor & Starter.

...more

Electrical Panel

Electrical Panel For Supply Of Electricity To Individual Motors. With Overall Suitable Size. It Has A Bank Of On/Off Switches Mcb/Mccb Of High Quality Make And Neatly Labeled With Separate Connections For Each Individual Equipments Of The Oxygen Plant. This Enables The Operator To Control All The Motors From One Point.

...more

Cylinder Filling Manifolds

Filling Manifold For Oxygen Complete With Stainless Steel Flexible Connections Two Racks For Switching -Pressure Gauges - Wika German -Safety Valves -Control Valves

...more

Cooling Tower

The cooling tower is induced Draft-Rotary Sprinkler type with aluminum Casting Fan, FRP Body with suitable Electric Motor for maintaining the circulating water temperature between the Hot well and Cold well for optimum performance of the Plant.

...more

Air Separation Plant

Our organization, an esteemed manufacturer and supplier, designs and develops a number of air separation plants that work in sync With the presence of well equipped production units and technically qualified workforce, our company designs and develops a number of plants, air separation plants, that work in sync with the plants of international standard. Our company is also getting assistance of known companies while designing and developing the air separation plants that produce oxygen and nitrogen from air through the process of compression, cooling, liquefaction and distillation of air. Our final outputs are unique in the industry in every parameter of Reliability, Durability and Functionality. Our air separation plants come up with diverse capacities ranging from 50 m3/hour to 5000 m3/hour, and start performing at 6 to 8 bar using Rotary air compressor from Atlas Copco, a US based company. The air compressor is popular all over the world for having a number of features such as automating functioning, energy efficiency and many more. The plant produces both oxygen as well as nitrogen with maximum purity, which is upto 99.7% and 99.99% respectively. The clients can acquire both gas as well as liquid, it depends upon their requirement. Notable features of air separation plants include: Fast, easy and safe to operate Compact and sturdy design Equipped with latest technology Practically zero maintenance Low power consumption No special civil foundation Unique stainless steel column

...more

Air separation column

Air Separation Column is a Packaged Unit with Outer Steel Casing, Main Heat Exchanger, Liquefier, Lower Column, Upper Column, Condenser, Dcpl Cooler, Liquid Oxygen /Nitrogen Filter. Stainless Steel Cooling Pipes, Insulation Material, Digital Auto Scanner With Temperature Meter Pt100 Sensor, DP Gauge Manometer Wika German /Feibig Expansion Valvesof Italian Design Stainless Steel Column Is Unique Feature.

...more

Air Compressor

Reciprocating Multistage Water Cooled Air Compressor, Complete With Flywheel, Intercooler, Foundation Bolt, Motor Pulley, V Belt, Belt Guard, Slide Rails, High Efficiency Dry-Type Suction Filter Complete With Motor & Starter. Four-stage balanced opposed layout eliminates unwanted vibration and valves provide extra long life.

...more

acetylene plants

Our company is designing, manufacturing and supplying acetylene plants in close association with Linde and Claude. With the latest technology and internationally approved components, our systems have become fully advanced and automatic. Our acetylene generating systems generate highly pure acetylene gas (C2H2), a compound of carbon and hydrogen is a colorless, garlic-like odor and a highly flammable gas. The gas has been generated by performing chemical reaction between calcium carbide and water. Our systems are performing exceptionally well over 40 countries in all over the world. Come up with different capacities that range from 15 m3/hour to 200 m3/hour, our acetylene producing systems are of an advanced design and incorporating many latest features not ordinarily found in other systems. This one is a fully automatic plant with a number of latest and uncommon features. We try our best to use the latest technology, quality raw materials and advanced components so that our systems perform for decades without wear and tear and fulfill the requirement of our customers. During the manufacturing process, we employ different teams to supervise the manufacturing process. Specifications: Plant capacity ranges from 25 m3/ hour to 200 m3/ hour Minimal Manpower Involvement Low Power Consumption Low Maintenance Cost Skid Mounted Technology Technology of Linde and Claude The systems manufactured in our facilities in India have to pass through a number of quality testing procedures so that we can bring a fully automatic and highly advanced system. Being a fully automatic and highly advanced system, it does not require much manpower involvement to perform. Apart from quality controlling teams, we also have shipping professionals to pack the systems in a manner so that they do not get damaged or misshaped during shipping. Get in touch with our customer care department for quotations and other information.

...moreBe first to Rate

Rate ThisOpening Hours