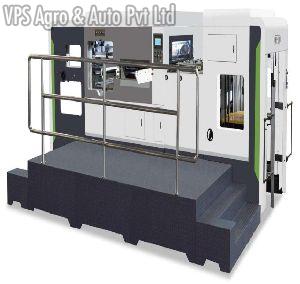

Hydraulic Die Cutting Press Machine

Get Price Quote

We offer Hydraulic Die Cutting Press Machine, which is known to deliver an efficient performance for long. We assure that Hydraulic Die Cutting Press Machine, which we offer, is stringently cross-checked on various parameters. What makes our Hydraulic Die Cutting Press Machine a preferred choice is its sturdy construction. We offer Hydraulic Die Cutting Press Machine at the market leading prices. Known For DurabilityReliabilitySturdinessHigh functional efficiency

Die Cutting Machine

455,000 Per Piece

1 Piece (MOQ)

Best Deals from Die Cut Machine

Flat Bed Die Cut Punching Machine

280,000 - 320,000 Per piece

1 piece (MOQ)

Plastic Sheet Die Cutting Machine

Get Price Quote

Our expertise lies in designing and developing Plastic Sheet Die Cutting Machine of remarkable quality. We precisely design and develop Plastic Sheet Die Cutting Machine with the help of technocrats. Designed to cater emerging demands, Plastic Sheet Die Cutting Machine ensures efficient performance and minimizes operational cost. Chiller We provide accessories that optimize compressor efficiency. With the correct selection of these accessories, technically oil and moisture-free compressed air can be provided. Air/Water-cooled after cooler version Downstream compressed air filters High pressure air drier High pressure receiver Suilt-in oil and moisture separator

Flat Bed Die Cutting Machine

Get Price Quote

Digital die cutting machine

240,000 Per Piece

1 Piece Piece(s) (MOQ)

printing slotting die cutting machine

3,500,000 Per unit

Die Cutting Machine

500,000 Per Piece

Die Cutting Machine

400,000 Per Piece

1 Piece(s) (MOQ)

Die Cutting Machine or Platen Punching & Creasing Press particularly designed for Die Cutting, Scoring and Creasing Work on PAPER, LINOLEUM, CARD-BOARD, CORRUGATED BOARD, FIRE-BOARD, CORK, LEATHER, PLASTIC AND PVC MATERIALS etc. Most Handsome and compact patronised Model requires Minimum Floor-Space. Minimum “Make-Ready” Time and provides sufficient hourly production.Basic DescriptionThe very sturdy construction of “Jenan” Die Cutting Machine or Platen Punching & Creasing Press guarantees for perfect works under heaviest conditions.Frame, Platen & Main Gears made of special high tensile Cast Iron are resistant to deformation even if subjected to greatest strain. The platen is driven from the ball bearing mounted shaft through a pair of reduction spiral gears protected by guards.The main gear shaft and connecting arms are mounted on Phosphor Bronze bushes.The reduction gear shaft is made of hardened high quality alloy-steel. Lubricated counter- pressure elements prevent the gears from deviating under the work pressure.Electromagnetic Clutch & Break SystemElectromagnetic clutch & brake in Die Cutting Machine enables push-button control of the machine for easy and efficient operation. Complete safety is ensured by full electrical interlocking. Electrical synchronization of both the clutch and the brake eliminates the possibility of time lag or over-lag between driving & braking. Instead of Pedal Control, there is a clean panel within operator’s easy reach from where all machine operations can be controlledDwell Timing DeviceThis timing device in Die Cutting Machine can be set to give a variable period from 0.5 to 10 seconds. During this time the platen remains stationary in the open position before automatically resuming motion at the end of the set dwell period. This is a particularly useful feature where feeding work requires a fine register or when large or difficult sheets are being fed which would otherwise have to be run using the single impression procedure. This device can increase output to more than double that of a machine on single impression working and can also be of great assistance during the training of an operator.This model differs from pedal controlled machines being driven by Electro Magnetic Clutch & Brake Unit and Training Control Dwell.Safety in the MachineAll moving parts on Die Cutting Machine are protected by approved safety guards. A special feature is the patented guard which protects the operator from the moving block. Should any object come between the moving block and this guard, a slight backward movement of the guard will occur stopping the moving block immediately and isolating the starting mechanism. Until the Guard is moved forward by hand the machine remains dead and isolated from any attempt to actuate it through the starting mechanism.Standard Features Platen Punching Machine is designed for Die Cutting, Creasing , Embossing and Half Cutting. Totally standardised (i.e. all parts are inter-changeable) All shafts are from EN-9/24 steel and pins are grinded & bushes from Phosphorus Bronze Alloy. All bearing are of SKF/NBC/NACHI only. Full-safe combination clutch brake system with adjustable system (up to microns). The main driving shaft is equipped sets of double helical self-lubricated imported poly amide driving gear. Main electric panel (operation and control) are equipped with International Standerized components i.e. Siemens/L&T/Schneider etc. Centralized Lubrication System is provided. Quick and simple adjustment of impressions independent through worm gear by eccentric bushes. All features that make the Platen Punching Machine most simple. reliable and maintenance free.

Midi Flex- Bpm Flexo Die Cutting Machine

Get Price Quote

1 Piece(s) (MOQ)

Envelope Die Cutting Machine

200,000 Per Piece

Flat Bed Die Cutting Machine

300,000 Per Piece

Automatic Foil Stamping and Die Cutting Machine

Get Price Quote

The machine is equipped with 3 sets longitudinal and 2 sets lateral foil feeding systems, to ensure the foil feeding stable, accurate, reliable tension controlling, less stretching, the foil feeding difference is only about 1mm. The waste foil collecting hair wheel is driven by imported servo motor, which ensures the high speed, stable, precise stamping work. Strong heat-resistant special material formed and processed honeycomb plate, could be located at any position. The heat-resistant stick and the anti-side-moving special block lay, makes the stamping more accurate and perfect. 12 individual temperature controlling zones, independent researched and developed “PID” precise controlled heating system, to keep the stamping molds temperature be stable, ensure the whole heating system’s temperature control be more equal and fast response.

Paper Die Cutting Machine

Get Price Quote

the most ideal paper roll die cutting machine for the paper cup industry.It is very suitable to cut the paper roll to sheets by wooden dies. It is PLC controlled. It is equipped with overload protecting system and has many more safety features. All the key parts are from reputed international brands which ensures the machine can run stable for a long time.

Single Die H.M. Machine

Get Price Quote

We bring forward high in performance Single Die H.M. Machine. Our Single Die H.M. Machine is made with the finest components and materials as per set industrial norms.

Die Cutting Machine

Get Price Quote

Die Cutting Machine

Get Price Quote

Die Cutting with LEAF Attachment

Get Price Quote

Salient Features• Popular Hot Foil Is attachment available in single, double and triple steps.• Step timer system for minimum foil wastage.• Digital temperature controller.• Auto foil rewinding system.• Specially designed heavy duty heater plate.

Die Cutting Machine

Get Price Quote

Creasing and Cutting Machines are special equipments for creasing and cutting ordinary cardboard, corrugated board, plastic and leather in general, applicable in printing, packing, decora- tion and plastic industries. Major Features:1. High strength due to one piece casting by using top quality materials for machine body. 2. Smooth running, big pressure and low noise are obviously remarked as 4-step helical gear mechanism is adopted. 3. Operational altitude is reasonably arranged.Moving-bed opens toits optimum. 4. Electrical system is designed in conformity with IEC standard. 5. Concentrated lubricating system.

Die- Cutting Unit

Get Price Quote

Chrome Plated Steel Tube Facet with special electronic gear design Thin blade slotting and die cutting synthesised accordingly. Co-ordinated line speed function in order to ensure the accuracy of the die-size line Complete Digital set up with programming control Also available as an individual attachment