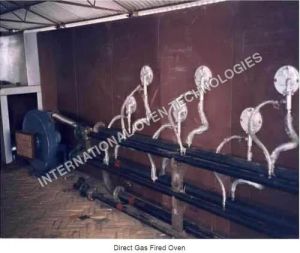

Direct Gas Fired Oven

325,000 Per Units

Direct Gas Fired Oven

Get Price Quote

Best Deals from Direct Gas Fired Oven

Direct Gas Fired Oven

Get Price Quote

Salient Features:- Structure: The structure for the full length of the oven will be fabricated by 75 x 40 mm channels and 50 x 50 mm angles and reinforced with cross frame jigs and gusset plates. These structures shall he erected at every 5 ft. distance and connected with 50 x 50 mm running angles. Insulating Panels: The 4" thick, side & top panels shall be fabricated by prime quality 16 gauge CRCA sheets with perforated sheet metal channels & are filled with mineral wool as insulation to avoid any heat loss to the atmosphere. Bottom portion of the oven shall be covered with 18 gauge CRCA sheets, which also protect the wickets & avoid heat loss. Conveyor: The full length of the oven will be consisting of alloy steel wickets having riveted construction fabricated out of rolled alloy steel wires of 8x3 and 7 x 2.5 mm dimensions. The extended pin type specially designed British standard chains will be used on which the wickets will be fitted with easy replacement system. The tensioning arrangement for the conveyor will be provided with sprockets etc. Mechanical varispeed system with HP motor shall be fitted to vari the speed of the conveyor. Oil Firing Chambers: There shall be nos stainless steel shell in shell type heat exchanger with firing chamber having exhaust fan mounted on top of the chamber. The oil burner with complete control system and the main circulating blowers shall be mounted on the either sides of the chamber. Complete chamber with suction box shall be insulated with glass/mineral wool panels & coverings to avoid heat loss, increasing the thermal efficiency. Gas Firing Chambers: There shall be 3 nos. stainless steel shell in shell type heat exchanger cum firing chamber. The automatic gas burner with complete control system and the main circulating blowers shall be mounted on the either sides of the chamber. Complete chamber with suction box shall be insulated with glass/mineral wool panels and covering to avoid heat loss, increasing the thermal efficiency. Air Ducts : The hot air will be from the top of the oven through nozzle type ducting fitted at both sides of the oven. The Diversion of supply air will be from bottom of both sides of the oven. Electricals : The electric motors, such as HP nos for main circular inline fan HP nos for burner, HP one no for driving 1 HP no for exhaust, 1 HP nos. for cooling, and 3 HP no. for solvent extractor fan are included in this quotation. Star Delta starters, for 10HP & above shall be used in the control panel. The wiring from control panel to motors and incoming to the are excluded from this quotation. The guarantee for electrical instruments and accessories shall not be covered by us. We supply the following accessories for Electrical & Control Instruments: Automatic temperature controller Flame Failure device: This is safety for the firing chamber, which operates in case of flame failure closing the solenoid valve automatically, thus stopping the oil flow. Interlock system is also provided not to operate burner unless the main circulating fan is on We shall supply automatic oil fired "Bentone" or equivalent burner