Vertical fine Boring Machine (mi-1500)

Get Price Quote

Vertical Fine Boring Machine (MI-1500) is precisely designed by our experienced and qualified engineers. It has a six speed gear box that aids it in providing heavy duty performance. This machine has long functional life. Standard Accessories : Boring tool setting device complete with a micrometer. Two tool holder for boring. Portable grinder with suitable grinding / lapping wheels. A set of service spanners. One spindle filted with machine having bore dia 68-135 mm. Extra Accessories : Spindle capacity-dia 81 to 200 mm Spindle capacity-dia 46 to 70 mm V-block stand Specifications Boring Range (With Standard Spindle) 64-140 mm Boring Range (With extra Spindles) 81-200mm, 46-70mm Boring Capacity 39-200 mm Maximum Boring Depth 500 mm Distance between spindle center to column 380 mm Spindle Speed Range 172-205-258-280-308-420 RPM Spindle feeds per revolution 0.002", 0.004", 0.006" Rapid movement up & down 750 mm Surface of table 1075 x 400 mm Table traverse (Longitudinal) 900 mm Table traverse (Cross) 50 mm Motor (Double speed) 2 HP 960-1440 RPM Rapid motor up & down 0.75 HP 2800 RPM Base area ( L x W) 1650 mm x 1400 mm Height 2400 mm Approx. weight 2200 Kgs Note : We reserve the right to modify the design & specifications because of continous improvement.

Used Radial Drilling Machine

Get Price Quote

We are actively engaged in providing Used Radial Drilling Machine. Our Radial Drilling Machine, even though used, is present in excellent working condition. Matching with the international standards, our Used Radial Drilling Machine ensures excellent performance with low maintenance requirement. Moreover, our Used Radial Drilling Machine models are easy to operate and are known for high drilling efficiency. With such attributes, the cost-effectiveness of the Radial Drilling Machine acts as an add-on for the clients.

Best Deals from Drilling Equipment

CNC HORIZONTAL BORING MACHINE SANCO SM FB100NC

1,100 Per Piece

Technical Specifications: Year Of Manufacture 1998 CNC Control FANUC OM Alpha Drive Chair Dimension 1100 x 800 mm T-Slot 20 x 7 mm Table Height From The Floor 850 mm Max. Table Load 1200 Kg Travels X Axis 1200 (1400) Y Axis 1100 (1300) Z Axis 800 (1000) Distance From The Bottom Of The End Of The Spindle From The Center Of The Table 300-1100 (300-1300) Spindle Center Distance From The Table Surface 100-1200 (100-1400) Spindle Motor 15/10 HP Speed (2 Steps) 2-3000 rev/min Clamping Cone ISO No 50/BT-50 Shift X, Y, Z Rapid Feed 10000 mm/min Cutting Feed 1-5000 RPM/min Min Input Growth 0.001 mm Servo Detector Pulsed Drive Motors OSY X-Y-Z 2.05 Hydraulic Circuit 0.75 KW Cooling Circuit 0.2 KW Lubrication Circuit 25 In Next Amount Of Oil For Hydraulics 45 Cooling Tank Volume 90 Amount Of Oil For Lubrication 4.6 Floor Plan Of The Machine 3900 X 3150 X 3130 mm Machine Weight 6800 Required Power 25 (30) NC Control System Fanuc

Conventional Drill Rods

Get Price Quote

Core Drilling Machine

Get Price Quote

Core Cutting/ Core Drilling Machine (Petrol & Diesel Engine) Product Specification: Suitable to cut/drill cores of concrete, rocks, stones, tiles or the similar materials. The machine is suitable for core samples of size upto 150 mm diameter with the help of thin walled diamond bits which are at extra cost.The machine has sturdy base with pillar support in which rack and pinion is provided for adjustment in height and penetration assembly. The leveling screws are provided at the base. For gripping the sample in position suitable grips are provided. A suitable petrol engine is fitted in the machine with cooling arrangement with water. The base frame is also fitted with wheels for ease of transportation. Dimension approx, are as under: Height : 1300 mm Base : 625 x 900 mm Head Travel on rack : 500mm Drill speeds : 900 R.P.M. for soft samples and 350 R.P.M. for hard Samples Water swivel : Built in the machines. Accessories : Thin wall diamond bits. Core barrel. Petrol engine 190 cc

Drilling Machine

Get Price Quote

With our rich industry experience, we manufacture, trade, distribute, wholesale and supply an extensive range of Ultrasonic Drilling Machine that is widely used drilling purpose. Our offered drilling machine is manufactured using premium quality components and modern technology in line with industry standards. Furthermore, this drilling machine is available in different technical specifications and sizes as per the requirements of the clients. Appreciated for its reliability, high strength and durability, this drilling machine is demanded in the market. Features: Low power consumption Easy usage Smooth functioning Other Details: Ultrasonic drilling machine is a device in which a method of brittle destruction by collision of abrasives is forced against a work by an ultrasonically vibrated tool assisted by an appropriate clamping force The tool vibration can be of amplitude approx Ultrasonic Vibrations run perpendicular/vertical on the work piece and drill/embosses precisely.

drill sleeve

Get Price Quote

We are offering drill sleeve.

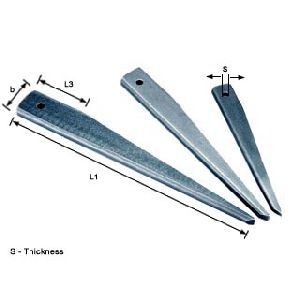

Drill Drift Key

Get Price Quote

Detail: drop forged from specially drawn medium carbon steel, these drift keys are accurately hardened for increased resistance to wear. description used for conveniently removing taper shank drills and remers from sleeves and sockets, these are blackened and have a premium shot blast finish with permanent marking of size for easy identification. fits following morse taper l1 l3 b s mm mm mm mm mt o 90 18 12 3 mt 1 & mt 2 140 25 20 5 mt 3 190 40 25 7 mt 4 225 40 30 10 mt 5 & mt 6 265 56 35 15 .

drill grinding machine

Get Price Quote

Double Ended Pedestal Grinding Machines are specially designed to provide heavy Metal removal in Engineering Workshops, Factories, Forging units, Foundries etc. Each Pedestal Grinder is complete with Electric Motor, Starter, Two Grinding Wheels, Two M.S. Wheel Guards with exhaust outlets, and two adjustable tool rests. The motor is fitted in the base of the Pedestal Grinder and the machine is equipped with 2 Speed V-Belt Drive. Arrangement is provided for increasing the spindle R.P.M when the Grinding Wheel Diameter is reduced. This helps to maintain the correct surface foot per minute Grinding speed.

Drill Machine

Get Price Quote

Rotation Unit

Get Price Quote

Carbide Tipped Integral Drill Rod

Get Price Quote

Vertical Core Drilling Machine

Get Price Quote

We are offering core drilling machine are light weight & compact size. It is work with 220v motor fitted at the top . The screw is provide at the bottom for the fixing at the site. high strength gear is provided for the long life. It has good speed for fast working. the core bit is also supplied with the machine. it is ideal used in the concrete, bitumen, reinforced concrete, brick in construction.

Horizontal Directional Drilling Machine

Get Price Quote

Radial Drilling Machine

Get Price Quote

We serve flawless Manufacturing, Exporting, Importing and Supplying a comprehensive range of Radial Drilling Machine. Our Radial Drilling Machines are highly durable and functional. All the raw materials used in the manufacturing of our Radial Drilling Machines are of high quality and heat treated to gain best possible durability. Our clients can avail these machines in different sizes, models as per their requirements. Features Safe & ReliableEasy to operate Main parts are made by machine center which import from KIA with high precision & efficiencyHigh Quality of Spindle Parts UsedHeat Treated DurabilityLow Noise

Pillar Drilling Machine

Get Price Quote

• Main spindle and pinion made from EN steel by forging. • Column, arm, work-head & gears made from finest closed grain cast iron; while spindle Ram trim Alloy steel. • Main spindle run out is checked for accuracy as per IS 2199. • For the smooth sliding of sliding arm, special 'slide-reliever-slots' are given. • All moving parts are fine-finished with grinding to a close tolerance. • International technic of 'Taper wedge setting'. for complete slide-setting instead of normal one point setting. • Quality bearings with grease bath, so for permanent oiling. • Main gear and pulley are perfectly balanced. • Powder coated accessories for longer life and prevention of corrosion and pillage associated with usual chrome plating. • P = Pillar Drill m/c • 19/25/40 = Drilling capacity • S = Square Head Model • R = Round Head Model • L = Long Spindle Travel • A = Autofeed Model • X = Xtra Heavy Model

Spm Machine

100,000 Per Piece

drill sleeve

Get Price Quote

We are offering drill sleeve, all sizes are available.

Drilling Rigs

Get Price Quote

We are offering drilling rigs.

ultrasonic drilling machine

650,000 Per Piece

Core Drilling Machine

Get Price Quote

Suitable to cutdrill cores of Concrete, Rocks, Stones, Tiles or the similar material. The machine is suitable for core samples of size upto 150mm diameter with the help of thin walled Diamonds Bits which are extra cost. The machine has sturdy base with pillar support in which rack and pinion is provided for adjustments in height and penetration assembly. The leveling screws are provided at the base. For gripping the sample in position suitable grips are provided. a suitable electric motor, standard make is fitted in the machine with cooling arrangement with water. the base frame is also fitted with wheels for ease of transportation.

water well drill pipes

100 Per Piece

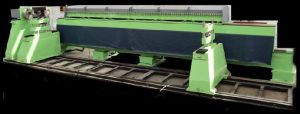

multi drilling machine

Get Price Quote

Zenith has designed its high performance Multi Drilling Machine for Drilling holes in Suction and Blind Drill rolls. These rollers are extensively used in paper mills all over the world as they are more efficient in draining of water than any other technique. Today most of the Paper manufacturing Companies across the world is using Blind Drill Rollers and we think that every paper mill roller manufacturer must have this machine to be able to manufacture such Rollers. Some of the salient features of the Machine are as follows :- Fully automatic with PLC controlled. Capable of drilling holes in rollers upto 8 to 10 meters as per standard. ( the drilling length can be increased or decreased as per requirement) Working diameter upto 1800mm Capable of drilling holes upto 3 - 5 mm diameter in size. The depth of the drilled holes is upto 6 -10mm as per standard. However the drilling depth can be increased if required. There are 175 drills to 300 in one line. Additional drills can be added if required. Roller with diameter 1800 mm can be drilled in 10 to 12 hour time. Roller weight carrying capacity upto 50 tons Power required to run this machine is about 30HP/ 22 kW

Paper Drilling Machine

45,000 Per Piece

Ethernet Media Converter

1,000 Per Piece

100 Piece (MOQ)

Drill blanks

150 Per Piece

500 Piece (MOQ)

Indexable Drills

Get Price Quote

We Provide An Ample Array of Superior Quality Indexable Drills that Provides Excellent Quality Surface Finish. Our Highly Efficient Adjustable Indexable Drill is Perfect for Concave and Slant Surface. We are Well Reckoned as One of the Supreme Carbide Indexable Drills Suppliers in India. We Offer Indexable Drills At Very Affordable Prices and that Too At a Very Brick Pace.

Bore Twisting Machine

Get Price Quote

We are leading manufacturer, supplier and exporter of huge range of bore twisting machine in india.

Radial Drill Machine

Get Price Quote

Radial Drill Machine

electro magnetic drill stand

Get Price Quote

electro magnetic drill stand, Portable Keyway Milling Machine