Wire Mesh Exhaust Gasket

To seal exhaust gases in most critical conditions inside Exhaust system, encountering extremes of mechanical vibrations, thermal shocks and high temperatures, we manufacture these ring gaskets in variety of raw material like, flexible Graphite, Mica, Stainless Steel wire mesh, GI wire mesh or any other customer specified material. The most successful reinforced with knitted wire mesh, wherein F.G and Mica are responsible to seal the gases while embedded and holed by knitted wire mesh.

...more

Spirally Wound Gaskets

Single or double V shape Stainless steel metal strip is spirally wound along with high temperature standing gasketing material like Flexible Graphite etc, Seal structure thus formed is having very high resilience to seal fluid and hot gases at extremes of temperatures, at the joints of flanges in pipe lines . Outer or inner metallic centering ring is provided to improve its functionality at high pressures in Industrial applications.

...more

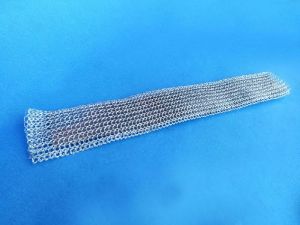

RFI Shielding Mesh

Knitted wire mesh provides a perfect solution to bridge gaps and leakage points in electronic enclosures. Strips and cores are produced in different cross sectional forms for mounting into extrusions. The outer layer of wire mesh provide an excellent shielding and elastomer or mesh core provides a high level of resilience. Cable wrap mesh is supplied in a continuous, flattened stocking, two-ply tape for shielding around cables and loom assemblies, in variety of materials like monel and stainless steel, tin or copper coated steel and aluminum.

...more

Multi layer Steel Gasket

Stainless Steel of spring quality and of thin thickness is coated is coated with special quality binder and is cut to desired shape and size of Cylinder head gasket, exhaust gasket etc. Multiple layers are assembled into single gasket. The high-temperature binder coating provides excellent fluid sealability across the outer faces and between the individual layers, while also sealing minor head and block surface imperfections. MLS head gaskets provide the ultimate in torque retention and supply extra strength to support lightweight aluminum casting designs. Though assembled as a single unit, all the layers acts independently adjusting themselces as barrier to escaping gases. Any further microscopic deficiency in escape route of gases is taken care by high temperature coating, thereby making the multi layered gasket structure, totally impervious.

...more

Metallic O Ring

Thin thickness Stainless steel or mild steel sheet is drawn in O shape and is stuffed with high temperature standing sealing material like Flexible Graphite. Conventional O-rings made out of various grades of Rubber have restrictions of use until particular temperature, pressure and working conditions. The metallic O rign structure so formed is having high mechanical strength and provide highly satisfactory sealing even at 1500 Celsius.

...more

Flexible Graphite Gaskets

natural graphite flakes are expanded to 300 times their original volume by chemical and thermal treatments, these expanded flakes are compressed under mechanical force to attain sheet of desired dimensions. During this processing all the layers of individual flakes get interlock with each other, their-by providing a regenerated single molecular structure. The sheet structure so obtained is flexble in nature and exhibit some unique properties: capable to with-stande temperatures from cryogenic to 2600� non-oxidizing atmosphere. chemically inert (with exceptions to few strong oxidizing reagents.) self-lubricatging. no binder or filler, infinite life. impervious structure. does not hardens or change its physical structure with time or when subjected to stringent conditions of high temperature and pressure. due to its laminar structure, flexible graphite exhibits very high degree of expansion, and fills-in even any microscopic deficiency in the mating surfaces their-by providing a perfect seal. Commonly used gasketing sheets are made out of fiberous materials, wherein fibers of various types are bonded together with elestomers and binders, how so ever good the fiberous material be, but when subjected to extreme conditions of high temperatures, pressures, thermal shocks , these elestomers and binders either get charred away or harden their- by leaving the composite structure prone to leakages. Flexible graphite sheets are mechanically bonded to tanged steel sheets. This no-reorque composite structure with above stated properties is now ready for cutting in any desired shape and size.

...more

Flexible Graphite

Due to its laminar structure, Flexible Graphite exhibits very high degree of expansion, and fills-in even any microscopic deficiency in the mating surfaces their-by providing a perfect seal. Commonly used gasketing sheets are made out of fiberous materials, wherein fibers of various types are bonded together with elestomers and binders, how so ever good the fiberous material be, but when subjected to extreme conditions of high temperatures, pressures, thermal shocks , these elestomers and binders either get charred away or harden their- by leaving the composite structure prone to leakages. Flexible Graphite Sheets are mechanically bonded to tanged steel sheets. this no-reorque composite structure with above stated properties is now ready for cutting in any desired shape and size.

...more

Exhaust Pipe Seal Ring for Automobiles

To seal exhaust gases in most critical conditions inside Exhaust system, encountering extremes of mechanical vibrations, thermal shocks and high temperatures, we manufacture these ring gaskets in variety of raw material like, flexible Graphite, Mica, Stainless Steel wire mesh, GI wire mesh or any other customer specified material. The most successful reinforced with knitted wire mesh, wherein F.G and Mica are responsible to seal the gases while embedded and holed by knitted wire mesh. Unlike sintered metal, by very nature of their granular construction, are prone to fracture or disintegrate when subjected to stress of thermal variations and vibrations. Knitted wire mesh consists of matrix of interlocking loops made out of monolithic wire. Loops acts as small spring free to move in any directions thus providing the structure extreme degree of resilience of better cavity fit under extreme conditions of mechanical vibrations and thermal shocks. Knitted wire mesh technology for gasketing and sealing systems provides lasting resilience, strength in compressions. These characteristics allow wire mesh sealing systems to perform under hostile environmental conditions where alternate materials would fail through decomposition or deformation.

...more

Acoustic Noise Suppression

Because of its basic structure, knitted wire mesh has proved exceptionally efficient in absorbing high energy sound. Acting as a physical barrier, when the sound energy hits the knitted metal element, it causes the wires to vibrate. The vibration causes �heat� (the conversion of acoustical energy to thermal energy ), thereby creating a damping effect. Mesh is virtually �custom tailored� to the specific needs of a given sound deadening application.

...more

Automotive

car stereo harness

Gland Packing Ring

End Protection Seals

Be first to Rate

Rate ThisOpening Hours