Trima Cyclones

Get Price Quote

We are a prominent entity, engaged in manufacturing and supplying a comprehensive assortment of Trima Cyclones, which is fabricated at our well-equipped manufacturing unit with the use of modern machines and sound technology. In order to meet the various requirements of clients, we offer our products in various specifications and dimensions. Clients can avail these products from us at market leading prices.

Trima Cyclone

Get Price Quote

Best Deals from Dust Collector Parts

Bag Filter

Get Price Quote

• Micron ratings from 1 to 200 • All industry standard & custom sizes available • Broad chemical compatibility • High flow/low pressure drop • Sewn or fully-welded construction • Handles on all bags • Choice of steel or molded plastic snapseal rings • Temperature ratings to 200ºF (PO), 275ºF (PE ), 425ºF (HT) and 500ºF (Teflon®

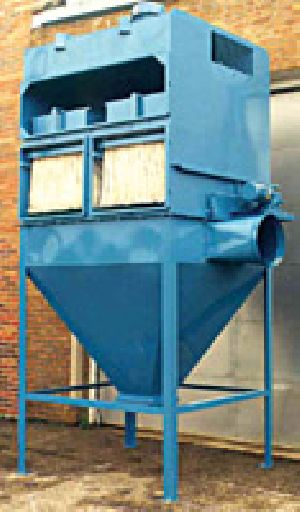

Cyclone Dust Collector

Get Price Quote

We are engaged in manufacturing and supplying Cyclone Dust Collector in the international market. The Dust Collector Cyclones, we offer, are generally used as dust collector for buffing and polishing machine and Multi cyclone is used as a dust collector for boiler in Thermal Power Plant. The clients can avail the Dust Collector Cyclone from us in varied specifications and at the market leading price. Details Dust Collector Cyclone has an M.S construction. Multi cyclone tubes are of cast iron with vanes. In Multi cyclone number of cyclone tubes is used as per air quantity, one cyclone tube of diameter 250 mm can handle up to 10 M3/min. Specifications Size : 400 to 1600 mmCapacity : 1250 M3/Hr to 30,000 m3/HrStatic Pressure : Approx 90mmwg in each case

Industrial Blower

Get Price Quote

Dust Collector

Get Price Quote

We are Manufacturing dust collectors for all types of dust/ powder in three type of shakingarrangement.1. Manual Shaking type.2. Mechanical Shaking type.3. Reverse Pulse Jet type. All type of dust collectors are having filter bag and the Bag is selected/designed as per the quality and properties of the dust/powder to collected/separated.In manual shaking type dust collector the Bag is cleaned manually by lever arrangement. In manual Mechanical type dust collector the Bag is cleaned by motor and cam arrangement. In manual Pulse jet type dust collector the Bag is cleaned by reverse pulsing of air at high pressure. The compressed air should be absolutely free from moisture and oil to avoid any dampness on the filter fabric. In each case the dust shall be drawn into the bag house by the centrifugal blower and fine dust shall be filtered on the inside or outside of the filter bag, thereby relatively clean air shall be let into the atmosphere.

Centrifugal Fan Blower

Get Price Quote

PECMA now offers a complete range of centrifugal fans. These fans are available in standard or varying widths of the impeller to suit exact duty conditions, optimize efficiency and conserve precious energy. Impeller are of MS For special applications, aluminum alloy, FRP lined or spark-proof construction are also available. Unique radial blade construction permits change in rotation in discharge direction and bi-directional rotation without affecting fan performance Two-Drive arrangement of impeller mounted on drive motor shaft and V-Belt. Rugged construction for trouble-free operationStatic efficiency up tp 70%Short delivery with fill range of accessoriesTwo-Drive arrangement of impeller mounted on drive motor shaft and V.belt Centrifugal and Axial Flows Fans Unrivaled Variety and Reliability Industrial Fan Range Centrifugal FansAxial Flow FansIndustrial MancoolersSpecial FansProcess FansAxial Industrial Ventilation & Air-Conditioning Fans Airfoil design impeller for peak efficiency for ventilation, air conditioning light industrial applications forced draft etc, in rugged construction. Single Or double inletsVolumes up to 250,000 m2/hr,pressures up to 750 mm weightCustom � built in varying impeller   diameter and widthsDifferent driving arrangementsStatic efficiency up to 84%CFull range of accessories PECMA are actively promoting the following efforts Monitor and reduction in emission of Green House Gases To reduce C02 EmissionDevelopment of technologies that involves green house gas, CO2 emission reductionEnergy saving, conservation & carbon reductionUtilization of renewable energy sourcesClean Development Mechanisms & development of the technologies & system for energy conservation & emission reductionDesign & Implementation of new technologies of new energy sources

exhaust centrifugal blowers

Get Price Quote

exhaust centrifugal blowers, kitchen ventilation equipment

bag house filter

Get Price Quote

bag house filter, TSE MBBR - Sewage Treatment Plant

Dust Collector

Get Price Quote

Dust Collector, protection bellow cover, Power Controller, Oil Skimmer

Nickel Filter Bag

Get Price Quote

Nickel Filter Bag, Liquid filter bag, titanium basket, MTC Rectifier

Oil Filter

Get Price Quote

Oil Filter, Air Filter, Fuel Filter

Dust Collectors

Get Price Quote

Dust Collectors, Axial Flow Fans, Centrifugal Blowers, FD Fans, Id Fans

Centrifugal Blower

Get Price Quote

Tube Axial Flow Fans, Boilers, Industrial Furnaces, air conditioning

Centrifugal Blowers

Get Price Quote

Centrifugal Blowers, Axial Flow Fans, Air Washers, Dust Collectors

centrifugal blower fan

Get Price Quote

centrifugal blower fan, Visi Cooler, Stainless Steel Water Cooler

Oil Filter

Get Price Quote

Oil Filter, Halogen Bulb, Ink, generator filter, hydraulic stainer filter

Bag Filter

Get Price Quote

Bag Filter, Material Handling Equipment, Pollution Control Equipment