Wheel Tracker Small Device

Wheel tracking is used to assess the resistance to rutting of asphaltic materials under conditions whichsimulate the effect of traffi c. A loaded wheel tracks a sample under specifi ed conditions of load, speed and temperature while the development of the rut is monitored continuously during the test. Test specimens can be either slabs prepared with a laboratory compactor or 200mm Ø cores cut from the highway. The CRT-WTEN1 wheel tracker performs both procedures A and B specifi ed for the small scale device in EN 12697-22. Procedure A requires that six specimens are tested. For procedure B only two specimens need to be tested, but rut depth must be measured at more points along the longitudinal rut profi le. To speed up the testing process the CRT-WTEN2 was designed to test two specimens simultaneously. KEY FEATURES• Tests materials for roads with axle loads up to 13 tonnes• Rigid test frame built from extruded aluminium section• Integral temperature controlled cabinet with double glazed doors• PID control of test temperature in the range 40°C to 62°C• Rack for pre-test temperature conditioning of specimens• The CRT-WTEN2 tests two specimens simultaneously• Specimens compacted with the Cooper Technology Roller Compactor can be transferred directly to the wheel tracker without de-moulding• Closed-loop speed control• User-friendly Windows™ software• Supplied with certifi cation of a UKAS accredited calibration KEY USES• Determination of the rut resistance of asphaltic paving materials

Feature : ests materials for roads with axle loads up to 13 tonnes • Rigid test frame built from extruded alum

...moreWheel Tracker Large Device

Wheel tracking is used to assess the resistance to rutting of asphaltic materials under conditions whichsimulate the effect of traffi c. In this machine, two 500 x 180mm specimens are tested simultaneously bytracking with wheels fi tted with pneumatic tyres under specifi ed conditions of load, speed and temperature while the development of the rut profi le is monitored at specifi ed intervals during the test.The moulded specimens are inserted and removed from the wheel tracker using an Easy-load system. A unique instrumented measurement device, linked to the data acquisition, is used to measure thedevelopment of rutting during testing. The test procedure and conditions are controlled and data acquired using Windows™ software running on a host computer via a high speed digital interface and signal conditioning system. KEY FEATURES• Tests materials for roads with axle loads of at least 13 tonnes• Unique rut profi le measurement device linked to data acquisition system• Integral temperature controlled cabinet• Test temperature range 40 to 60°C• Tests for specifi ed number of cycles or to specified rut depth• Double glazed doors for viewing test• Easy-load system for specimen handling• Conditioning of specimens at test temperature• User friendly Windows™ software• Automatic test start/stop• Closed loop speed control• Specimens can be compacted in the CRT-RCENLD-II and then wheel tracked without demoulding• Supplied with certifi cation of a UKAS accredited calibration KEY USES• Determination of the rut resistance of asphaltic paving materials

Feature : Tests materials for roads with axle loads of at least 13 tonnes • Unique rut profi le measurement de

...more

Vacuum Ovens And Viscometer

3606 PAV vacuum oven is designed for use in the degassing process of the binder material that has been removed from the Pressure Aging Vessel in accordance with AASHTO PP1-98. Immediately following the degassing process, the material can then be tested in the Bending Beam Rheometer, the Dynamic Shear Rheometer or the Direct Tension device. Degassing of the material prior to these tests insures that the material does not contain air bubbles. Entrapped air can compromise the integrity of the binder material, thus causing false failures in the previously mentioned test devices.

...more

Vacuum Ovens

3606 PAV vacuum oven is designed for use in the degassing process of the binder material that has been removed from the Pressure Aging Vessel in accordance with AASHTO PP1-98. Immediately following the degassing process, the material can then be tested in the Bending Beam Rheometer, the Dynamic Shear Rheometer or the Direct Tension device. Degassing of the material prior to these tests insures that the material does not contain air bubbles. Entrapped air can compromise the integrity of the binder material, thus causing false failures in the previously mentioned test devices.

...more

Ultrasonic Pulse Velocity

The Pundit Lab is an ultrasonic pulse velocity (UPV) test instrument which is used to examine the quality of concrete. It features online data acquisition, waveform analysis and full remote control of all transmission parameters. Along with the traditional transit time and pulse velocity measurement, the ultrasonic test equipment Pundit Lab offers path length measurement, perpendicular crack depth measurement and surface velocity measurement. Optimized pulse shaping gives greater transmission range at lower voltage levels. This, coupled with automated combination of the transmitter voltage and the receiver gain, ensures an optimum received signal level, guaranteeing accurate and stable measurements. An integrated waveform display allows manual triggering of the received waveform.

...more

Two Point Trapeziodal Bending Beam Machine

Bending tests are widely used for measuring the stiffness modulus and assessing the fatigue resistance of asphaltic paving materials. The two-point bending test on trapezoidal specimens is, arguably, the most repeatable and reproducible bending test method detailed in the relevant EN12697 standards. In this test the specimen is mounted as a vertical cantilever. The base is fi xed and the top is moved sinusoidally with a constant displacement amplitude. The trapezoidal shape ensures that the maximum values of bending stress and strain occur away from the ends of the specimen where there are likely to be stress concentrations. With the Cooper Technology equipment, two trapezoidal specimens are tested simultaneously and stiffness modulus can be determined at a range of frequencies and temperatures. In the fatigue test the specimens are subjected to a constant strain amplitude at a selected frequency and temperature until the stiffness modulus decreases to a user-selected target level (normally 50 percent of its initial value). KEY FEATURES• Rigid test frame housed within temperature cabinet• Temperature cabinet with fan assisted air circulation and glazed viewing door• Temperature cabinet range -20 to 30°C• Machine designed to test two specimens simultaneously• Frequency range from 0.1 to 35Hz• Precise manual setting of strain amplitude• Accurate pre-test displacement transducer adjustment using software feedback• Two high-precision ±2.5kN fatigue rated piezoelectric force transducers• High-speed control and acquisition system for interfacing to host computer• User-friendly software for fatigue and stiffness modulus tests• Software for automatically carrying out frequency sweeps KEY USES• Mixture design• End product specifi cation• Assessment of new materials

Specialities : • Rigid test frame housed within temperature cabinet, • Frequency range from 0.1 to 35Hz

...more

Triaxial Force Balanced Accelerometer

Recommended for strong motion earthquake survey & industrial applications requiring

...more

Thermolyne NCAT Moisture Determination Oven

A fully automatic moisture determination oven for asphalt mix, aggregates, and soils available now from the same innovative company that brought you the NCAT Asphalt Content Kiln. A sample is dried to .01% of initial sample weight. This durable unit complies with ASTM 2216-92 and numerous state D.O.T. oven drying methods. Currently there is an ASTM Provisional Standard in subcommittee D04.25 detailing the use of this unit to determine moisture content in Hot Mix Asphalt.

...more

Thermo Tracer

Features High quality image 320 x 240 pixel radiometric Uncooled Focal Plane Array equippedEasy to holdSingle hand control with either right or left hand Large memory capacity Stores 400 images in the internal flash memoryFlip-up 3.5 inch LCDAdjustable for suitable angle to your eye position Operability Operates for 2.5 hours with rechargeable batteryTransfers images to PC via USB2.0 Laser pointer Shows measuring position Power saving Stand-by and auto shut-down functions to save power consumption Robust Dust/splash-proof IP54Shock 294m/s2(30G)Vibration 29.4m/s2(3G)

...more

Thermal Integrity Profiler

The Thermal Intergrity Profiler (TIP) uses the heat generated by curing cement (Hydration energy)to assess the quality of cast in place concrete foundation such as drilled shafts,bored,augered cast-in-place (ACIP),continuous flight auger (CFA) and drilled displacement piles.

Manufacturer : PDI

...more

Surface Penetrating Radar

USRADAR offers the means to detect buried objects that are not detectable by other methods. In addition to the ability to locate metallic objects, USRADAR is able to detect nonmetallic objects. The system sends radar pulses into the surface, then it receives and processes the reflected energy. Through advanced processing technology the system calibrates to the dielectric constant of the surrounding material. When the signal is reflected from a material having a different dielectric constant, the signal is displayed on the screen as an anomaly. Depth can also be determined by processing the sampling interval and determining anomaly. Depth can also be determined by processing the sampling interval and determining the size and comparing relative data of other objects detected.

...more

Strain And Acceleration Sensors

Strain Transducers and Accelerometers manufactured by Pile Dynamics collect the essential data for use with the Pile Driving Analyzer® (PDA) and SPT Analyzer. Reliable results start with reliable measurements: The axially accurate strain and acceleration signals collected at high microstrain and “g” levels are converted by the PDA (or the SPT Analyzer) to force and velocity records. These records are then used in evaluations of foundation capacity, foundation integrity,hammer efficiency and pile driving stresses. Accuracy matters, but so does convenience. PDI sensors are fast and simple to install and remove. With proper care, both accelerometers and strain transducers have a long useful life. Sensors are quickly bolted to any type of foundation, usually about 2 to 3 diameters below the top. Strain transducers are attached symmetrically to account for bending effects. Accelerometers should be attached near the strain transducers. Attachment is typically performed with drilled and taped holes for steel pipe piles, clearance holes with bolt/nut for steel H piles, lag bolts for timber piles, or by installing embedded anchors for concrete piles and shafts.

...more

Acceleration Sensors

Strain Transducers and Accelerometers manufactured by Pile Dynamics collect the essential data for use with the Pile Driving Analyzer® (PDA) and SPT Analyzer. Reliable results start with reliable measurements: The axially accurate strain and acceleration signals collected at high microstrain and “g” levels are converted by the PDA (or the SPT Analyzer) to force and velocity records. These records are then used in evaluations of foundation capacity, foundation integrity, hammer efficiency and pile driving stresses. Accuracy matters, but so does convenience. PDI sensors are fast and simple to install and remove. With proper care, both accelerometers and strain transducers have a long useful life. Sensors are quickly bolted to any type of foundation, usually about 2 to 3 diameters below the top. Strain transducers are attached symmetrically to account for bending effects. Accelerometers should be attached near the strain transducers. Attachment is typically performed with drilled and taped holes for steel pipe piles, clearance holes with boltnut for steel H piles, lag bolts for timber piles, or by installing embedded anchors for concrete piles and shafts.

...more

Standard Penetration Test Analyzer

The Standard Penetration Test (SPT) is a widely used soil exploration tool that involves using a SPT hammer to drive a split barrel sampler at the bottom of a drill string to obtain soil samples. The number of blows required to penetrate the last 300mm (1ft.) is the “N value”, which is related to soil strength. SPT Analyzer For Improved Reliability of SPT N-values Determines the Energy Transferred by SPT Hammers using Force and Velocity Measurements - Conforms to American Society for Testing and Materials Standards: • Energy measurements are recommended to normalize results (N-values) from SPT tests (ASTM D1586) • Normalization of N-values based on energy measurements are required when SPT results are used to determine the liquefaction potential of sands (ASTM D6066) • The only ASTM accepted means of determining energy for normalization of N-values is by force and velocity measurements (ASTM D4633) - Assesses the efficiency and consistency of operation of SPT rigs.

...more

Stand Alone Four Point Bending Beam Machine

Bending tests are widely used for measuring the stiffness modulus and assessing the fatigue resistance of asphaltic paving materials. Four point bending tests are included in CEN, AASHTO and Chinese test specifi cations. The specimen is a prismatic beam which is subjected to sinusoidal loading in either the controlled strain or controlled stress modes. The CRT-SA4PT-BB uses advanced servo pneumatic technology and a high-speed digital data acquisition and control system together with user-friendly software. During testing both graphical and tabular data are displayed on screen and test data is stored to disc in Microsoft Excel™ compatible format. The clamps are at 118.5mm centres (the distance between the outer clamps is 335.6mm (14 inches) according to AASHTO specifi cations2 but the height and width of the beam can be varied. 2 Tests on beams containing aggregates greater than 20mm are not strictly in accordance with annex D of EN 12697-24 which states that this non-compliance should be explicitly mentioned in the test report.

...more

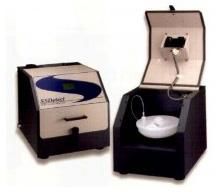

SS Detect System

An automated device for determining the Saturated Surface Dry condition and Absorption of fine aggregates. ASTM C128-93 and AASHTO T84-95. This device will provide more accurate and repeatable Bulk Specific Gravity and Absorption values for fine aggregates.

...more

SilverSchmidt Rebound Hammer

The SilverSchmidt ST/PC is the first integrated concrete test hammer featuring true rebound value and unmatched repeatability. Two factors contribute to the improved performance of this concrete test hammer over its predecessors: Velocity based detection of the rebound quotient The lightweight hybrid design of the impact plunger is made from aerospace alloy, matched to the elastic properties of the concrete and equipped with a hardness steel cap Independent validation testing by BAM (Federal Institute for Materials Research and Testing, Germany) has shown the SilverSchmidt ST/PC to have less dispersion than the classical concrete test hammer over the entire range. The unique design and high quality construction of the concrete test hammer SilverSchmidt ST/PC makes rebound hammer testing quicker and more accurate than ever before.

...more

ShearTrac II Volume Pressure Controller

ShearTrac-II operates as an intelligent loading system. It uses feedback from transducers to provide real-time control of the load frame. Two force transducers (horizontal and vertical) and two displacement transducers (horizontal and vertical) are the sensors for the ShearTrac-II unit. The computer loads or unloads the load frame until the readings from the transducers equal the values required to meet the test specifications. The loading mechanism to apply normal loads is raised and lowered by a micro-stepper motor connected to a worm gear. The loading mechanism to apply shear loads is moved left and right by a second combination of micro-stepper motor and worm gear. Limit switches for both horizontal and vertical motions prevent running the loading mechanism beyond its physical limits. The standard ShearTrac-II unit uses a 16-bit AD card. This means that the raw data reading units are on an integer scale from 0 to 65536 (0 to 216). Each reading unit is also called a count. These count readings must be converted to engineering units. The system is supplied with calibration factors that do this conversion. The system uses calibration data to relate count readings to engineering units. Because ShearTrac-II is an intelligent loading system, all components must be functioning correctly for the system to operate. All operation of the load frame must occur through the computer for full automation. Separate manual operation is possible through front panel keypads. To avoid damage to any component, readings from all sensors are checked by the computer hundreds of times per second. Any analog or digital reading outside the acceptable condition prevents the micro-stepper motors from running.

...more

Servo-Pneumatic Universal Testing Machine

This machine is a development of the NAT which was developed by Keith Cooper and Professor Steven Brown at the University of Nottingham. The use of a high precision servo-pneumatic valve in conjunction with a low-friction actuator and sophisticated data acquisition and control, results in a performance that is equal to many servo-hydraulic systems. Accurate, digitally generated waveforms are applied by the actuator producing repeatable stress variations in test specimens that are simulative of those in a road pavement due to moving traffic. The actuator is double-acting allowing both compressive and tensile forces to be applied. A triaxial cell system is available for the measurement of the resilient modulus of unbound materials.

...more

Servo-Hydraulic Universal Testing Machine

The Servo-Hydraulic Universal Testing Machine (CRT-UTM-HYD) is a well designed, inexpensive machine specifi cally developed for the testing of materials used in pavement construction. A motorized, adjustable crosshead reduces the time between test setups. The programmable temperature cabinet provides the possibility to perform frequencytemperature sweeps. Accurate waveforms are digitally generated and applied by the actuator producing repeatable conditions that are simulative of those created by moving or static vehicles. The actuator is double-acting allowing both compressive and tensile forces to be applied. Various systems are available for the measurement of the modulus of unbound materials.

...more

Resipod Resistivity Meter

Resipod is a fully integrated 4-point Wenner probe, designed to measure the electrical resistivity of concrete in a completely non-destructive test. It is the most accurate instrument available, extremely fast and stable and packaged in a robust, waterproof housing designed to operate in a demanding site environment. The Resipod is the successor of the classic CNS Farnell Resistivity Meter. Surface resistivity measurement provides extremely useful information about the state of a concrete structure. Not only has it been proven to be directly linked to the likelihood of corrosion and the corrosion rate, recent studies have shown that there is a direct correlation between resistivity and chloride diffusion rate and even to determination of early compressive strength. This makes it one of the most versatile NDT methods for concrete Fully integrated surface resistivity instrument Highest resolution available for a surface resistivity instrument Available with 1.5″ (compliant with the AASHTO standard) or 50 mm probe spacing Current flow indication and poor contact indication Hold, save and delete function, with onboard memory USB connection and dedicated PC software Designed to float (waterproof) Allows replacement of standard tips with accessories

...more

Rebound Hammer

The SilverSchmidt STPC is the first integrated concrete test hammer featuring true rebound value and unmatched repeatability.Independent validation testing by BAM (Federal Institute for Materials Research and Testing, Germany) has shown the SilverSchmidt STPC to have less dispersion than the classical concrete test hammer over the entire range. The unique design and high quality construction of the concrete test hammer SilverSchmidt STPC makes rebound hammer testing quicker and more accurate than ever before.

...more

Rebar Locator

The Profoscope+ is a fully integrated rebar locator with data storage. To increase the efficiency on the construction site this enhancement of the Profoscope not only offers real time visualization of rebars, but also automatic data collection. Writing down measuring results of testing series is a time consuming business that can be an unnecessary source of errors. The various data storage modes of the rebar locator Profoscope+ make note taking obsolete. This cordless rebar detector is ideally suited for one-handed operations, keeping the other hand free for marking rebars. The rebar locator Profoscope+ has the same features as the Profoscope, but additionally offers the innovative memory function for data acquisition. The included Windows based software ProfoLink offers the possibility to comfortably download, edit and present the data measured by the rebar locator. Data exchange can be done easily by connecting the rebar locator Profoscope+ directly to the USB-port of the PC or by reading out the integrated Micro SD memory card.

...more

rebar detector

The Profoscope is a versatile, fully-integrated rebar detector and cover meter with a unique real-time rebar visualization allowing the user to actually “SEE” the location of the rebar beneath the concrete surface to a maximum depth of 180 mm. This is coupled with rebar-proximity indicators and optical and acoustical locating aids. Rebar diameter can also be estimated within the specified testing range. The Profoscope combines these unique features in a compact, light device that allows the user to operate this rebar detector with one hand making the task of locating rebars a simple and efficient process. In addition, Proceq’s rebar detector convinces through its intuitive user interface making rebar detection easy.

...more

CAse Pile Wave Analysis Program (CAPWAP)

CAPWAP – CAse Pile Wave Analysis Program – determines static soil resistance and simulates a static load test. CAPWAP uses force and velocity data measured on a foundation impacted by a ram to determine: - Static shaft resistance, magnitude and distribution - Static end bearing - Stresses at any point along the shaft - Energy transferred from the ram to the foundation Measurements are made with a Pile Driving Analyzer®. CAPWAP simulates a static load test and predicts the instantaneous load settlement behavior of the tested foundation. CAPWAP 2006 has improved help functions and features that enhance the analysis of drilled shafts and auger cast-in-place piles.

Manufacturer : PDI

Model Number : CAPWAP® 2006

...more

US Radar Ground Penetrating Radar

Ultrasonic Pulse Velocity Testing Service

Be first to Rate

Rate ThisOpening Hours