edm oil

Get Price Quote

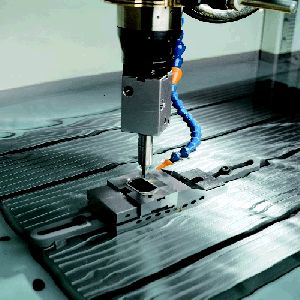

Electric Discharge Machining Oil is a metal removal process involving the removal of material from the work piece by a series of controlled electric discharges or sparks. The tool and the work piece are insulated by a special dielectric fluid. These fluid are formulated with a highly refined, narrow cut paraffinic base stock with excellent oxidation stability which helps reduce the formation of oxidation products that will alter the dielectric strength of the fluid. The product is colourless and virtually odourless. The product exhibits a relatively high flash point that helps to reduce the possibility of fire. The low viscosity of the fluid provides good circulation through the spark gap and more rapid removal and settling of metal fines. Application / Composition of EDM Oil Recommended for use in:Dielectric fluid in finish-cut electrical discharge (spark erosion) machining operations.Electrical discharge machining in tool and die shops, and in manufacture of electronics, extrusions, air-craft components, hardware, tools, fasteners, silver-ware, cutlery, jewellery, appliances, valves and regulators. Grinding fluid in glass grinding operations.

edm oil

149 Per Litre

100 Litre (MOQ)

Make a good impression on potential customers by eliminating the smoky, smelly, kerosene based edm oil is an easy way to clean up your image, and improve your bottom line.Sun chem brand edm oils are multipurpose dielectric fluids for use in all discharge machines especially for roughing, finishing and superfinishing work. These are formulated with high-purity fluid designed for maximum machine productivity and operator comfort when used in electrical-discharge machining. The chemistry of these products provides correct balance of viscosity, volatility, oxidation stability, heat transfer characteristics and low toxicity. They are highly refined, narrow-cut, low-viscosity fluids and function as an insulator between tool and workpiece.Do you know how to choose edm dielectric oil If you are old enough to remember the days of injection mold making with disgusting edm dielectric oil you qualify to to appreciate how clean, odorless (almost) and safe the fluids found in sinker edm’s are these days. Work floor used to smell like a diesel at the end of the with all those disgusting fumes that soaked into the lungs. After all, the odors we smell are actually tiny particles of matter that get picked up by our noses. Not only will the use of up-to-date edm oil enhance your profits, it will also boost morale of the edm department and not be offensive to visiting customers. Advantages of quality edm dielectric oil Faster machining speeds-the newer oils are highly refined and purified to be more efficient. They are engineered to burn cleaner, thus producing a finer finish more quickly. Less smoke-the smoke produced from high amperage burns can produce quite a bit of toxic smoke, which must be vented to the outside. Even then, what becomes of the smoke? Longer fluid life-because they enable electrical discharge machining to be more efficient, the heat and sludge does not degrade the oil as quickly. This can mean quite a savings in material and time. Easy on the skin-many operators complain of skin irritation from the old kerosene based fluids. The new synthetic edm oils are much easier on the skin. Does not evaporate-your oil will last longer, and your shop will not smell like a diesel engine repair shop. Environmentally friendly-because the new edm oils are synthetic they are much easier to dispose of and have less impact on the environment. You only get once chance to make a good first impressionChoosing the correct edm oil can make a substantial difference in the overall performance of your edm department. Buying good edm supplies makes sense any way you look at it.

Best Deals from EDM Oil

edm oil

14,500 Per Barrel

1 Barrel(s) (MOQ)

FUZONE EDM oil/ Spark Oil are made from best in class imported raw material for electric discharge machine with the highest flushing power. Electro discharge machining (EDM) is a sophisticated process used to shape complex and highly defined components which cannot be machined with convectional methods. So Oil must be able to fulfill the process demands, which our product does meet without ease. APPLICATION For use in EDM equipment as an spark Erosion Oil PERFORMANCE BENEFITS Lower electric conductivity for better spark control and higher machining definition Higher flash points for greater safety margins and higher-power sparking Negligible odor aromatics for increased worker comfort High thermal and chemical stability for longer fluid life. Non-toxic and non-corrosive. Help control equipment temperature

edm oil

Get Price Quote

EDM: series stones are specially for removing the hard scale generated by the EDM process on all type of mold and die steels.

edm oil

Get Price Quote

mobile oil, Transformer Oil, Hydraulic Oil, Lubricating Oil, linseed oil

edm oil

Get Price Quote

Cutting Oil, Engine oil, Hydraulic Oil, Industrial Lubricants

edm oil

Get Price Quote

DC Servo ZNC EDM Machine, AC Servo ZNC EDM Machine

edm oil

Get Price Quote

Drill Chuck Keyless, Electrode Tubes Multi Hole, Sodick EDM Filter

edm oil

Get Price Quote

Hydraulic Oil, Edm Machines

EDM Spark Oil

Get Price Quote

EDM Spark Oil, Mobil Motor Oil, Knitting Oil