Volumetric Liquid Filling Machine

An exquisitiely designed machine to fill bottles of different shapes and sizes with any kind of free flowing liquid viz. Drugs, syrups, after shave lotions, milk, beverages, oils, squashes, adhesives, varnishes, spirits, perfumes, chemicals, etc. The machine is cabinet model made of mild steel and painted with Acrylic base paint. The liquid contact parts and one top of the cabinet is made of stainless steel. The machine is fitted with a vaccum pump driven by a 0.25 and 0.5 H.P. electric motor and an overflow jar with a drain value. This machine is offered in two head and four head varieties to fills bottle ranging from 2" (50mm) to 13" (325mm) height. The nozzle size ranges from 5mm to 12.5 mm.

...more

VLT Micro Drive

The VLT® Micro Drive is a general purpose drive that can control AC motors up to 22 kW. It’s a small drive with maximum strength and reliability. RoHS compliant The VLT® Micro Drive is manufactured with respected for the environment , and it complies with the Rohs Directive. The perfect match for : Industrial appliances HVAC application OEM Power range : 1 phase 200 - 240 V AC: 0.18 - 2.2 kW 3 phase 200 - 240 V AC: 0.25 - 3.7kW 3 phase 380 - 480 V AC : 0.37 - 22 kW

...more

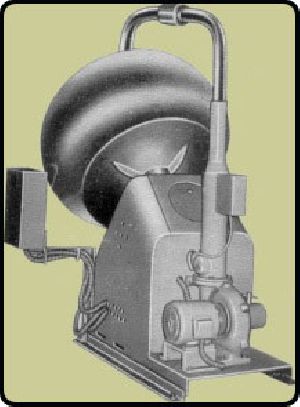

Vertical Blender

Establishment in 1842, in Rochester, New York, USA, CHARLES ROSS & SON CO. is today arguably the leading manufacture of Mixing, Blending ,Dispersion Equipment's in North America. The BECTOCHEM ROSS Alliance between two highly vibrant organisations, hearlds a new era in the launch of such equipment as the Vertical Blenders, offering modern day technology for these equipment's at your doorsteps. The Vertical Blender is a Versatile Blender / Mixer used in a wide range of applications. Its unique triblending action achieves the shortest possible mixing times. The mixing Screw moves material upwards and in spiral motion. The upwardmotion is combined with a secondary interna; movement along the periphery. The typical conical shape of the Vessel helps in cascading material from top to bottom. Ross Vertical Blenders are available in sizes from a popular 35 lts lab unit to 15000 lts production models. Vaccum and Non-Vaccum application with heating and cooling jackets are available along with Dry/Distilling systems based on user specifications and suitable for Adhesive, chemical, Coatings, Cosmetic, Food, Pharmaceutical and Plastic Industries. Ross Blenders have the unique advantage of: Efficient mixing. Complete discharge. NO PINTAL Bearing at bottom due to improved Swing ARM design. Full load start up. Low Floor space. Reduced HP leading to lower operational costs. The unit comes with the complete back up support of BECTOCHEM & ROSS Customer service, all across the globe.

...more

Conical Screw Vacuum Dryer

This 3 cu. ft. machine is designed for operation under vaccum and internal pressure to 90 psig. The unit is constructed in stainless steel and is provided with a 125 psi jacket which is insulated and sheathed. A2" sampling port is mounted thorough the cone wall near the bottom and a manually operated valve is mounted on the bottom for complete discharge of blended materials

...more

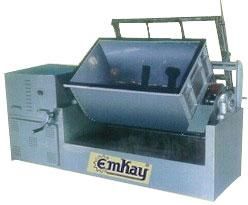

Two Roll Mixing Mill

Two Roll Mixing Mill Developed for your unique mixing applications, high productivity through advanced design. Emkay Two Roll Mixing Mill is a highly developed range of equipments for Rubber, Plastic and other Polymers with high productivity and consistently good mixing with minimum energy consumption. Engineered for easy maintenance. Featuring self contained and floor mounted. Eliminating the need for foundation or grounting. It is very easy to install Emkay Two Roll Mixing Mill. Salient Features Low, initial cost Clean, safe environment. Less operational cost with high productivity. Superior mixing performance. We manufacture complete range of Two Roll Mixing Mills from lab size 6" x 15" upto a production Mill of 26" x 84". Refiners, Crackers, Grinders (flutted/grooved rolls) for reclaim rubber industries and crumbing/refining of wastage from footwear industry. We can manufacture special mills as per the requirement and specifications of the customers. Each mill is designed to absorb heaviest specified mixing load with minimum deflection. The standard friction ratio of the mills are 1: 1.25 app. Which can be varied upon customer's requirement. Rolls speeds are based on the rheological characteristics & compound to be processed to assure the best possible quality & productivity. Emkay Mixing Mills are designed to run lower or higher RPM than standard as per specifications given by customers (it is optionally). Variable speed is also supplied (DC drive/ hydraulic drive. Optionally).

...more

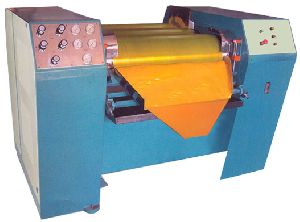

Triple Roll Mill Machines

We have been able to manufacture an array of triple roll mill. The rolls are internally cooled with water to percolate undesirable heating of the mass during operation. There is continuous water circulation system in all the rollers. The advantages of the three roll mills in the mid and high viscosity range permit the dispersion of a product with a low liquid content, which can shorten the overall processing time considerably. Since liquids do not have to be dispersed, they can be added afterwards.

...more

THREE SPEED PLANETARY MIXER

MFI THREE SPEED PLANETARY MIXER M/c with all contract parts of ss-304, ISI MARK STANDARD MOTOR, starter and suitable 3-speed old car gear box, with SS-bowl, specially dcesigned slow speed beater rotating planetarily, hand operated mechanical up & down lifting device, etc. Available in 50/100/150/200/250 kg batch capacity models.

...more

Steam Jacketted Vessels

Jacketed pan inside contact SS sheet 304 quality non-magenetic 10 SWG on outside M.S. sheet 10 SWG oil circulated heating system with 3 KW electric heater (3nos) totally enclosed with glasswool in between the M.S & M.S. Tank.with thermostate control tempreture guage volt meter, ampere meter and safety wall fitted in electric panner mounted on M.S. fabricated stand, hearing shaft fitted in both sides with hearing blocks and gear box fitted at one side and tilting system complete inside chrm finish and outside DUCO paints finsh complete.

...more

Stamping Die

Single Cavity Die set for soap is made up of Gun Metal comprises an engraving on the upper side and series of the interchangeable number. The letters are furnished for positioning in two rows on lower dies. Die shell are of high precision and polished spring loaded inserts ejecting arrangement is made to release the stamped soap from the die.

...more

Stainless Steel Horizontal Plate Type Filter Press

This is the unit for clear filteration of liquid chemicals cosmetics, beverages, oil inks, which consists of a strng stainless steel tank with top cover and tightening bolts in the centre of the tank a filtering unit is fitted consisting of dic type filter plates with perforated screens, filter media end interlocking cups.The filter press is coupled with a stainless steel transfer pump with motor and mounted on a portable base covered with staainless steel sheet and castors are also provided. For viscous Liquids s.s. Gear pump can also be provided. when the liquid to be filtered is passed on the filters tank by the transfer pump, it reaches the top of the plates through the circular openings on the sides of the plates.The filter media arrests suspensions and allows the filterate to pass through them and the screens. It runs down the central vertical channel formed by the inter locking cups, and finally goes out of the outlet pipe). Though this type of filter press is used for obtaining filte ate in certain cases cakes can also be obtained in the space between the plates.

...more

Stainless Steel Cylindrical Tanks

Emkay stainless steel cylindrical tanks This unit is made out of stainless steel sheets (304 Quality) with weldings done by Argon Arc process. The tanks are polished and buffed from inside and outside to give mirror finish and are supplied complete with lid l outlet valve with nose nipple M.S stand with castor wheels etc. (25 Lts. to 100 Lts are supplied without valves and stand. The diamensions are approximate and are subject to change depending on the availability of S.S Sheets).

...more

Stainless Steel Coating Pan Machine

This machine is very simple and efficient in one complete unit with stainless steel Pan of size 90 cm.dia.The machine is worked by oil immersed reduction gear. Blower is operated independently with motor and starter and air is thermostatically controlled to give air from room temperature to 90oC. Entire unit is of sound construction, well painted and good deisign. The complete unit is exctly similar to German Water Brucks make.

...more

single compression

Sigma Mixer

Emkay designed, double arm kneader mixer is most suitable for preparing solids, pastes, high viscos substance, with special version for heating and cooling system, pressure and vacuum operations with mechanical or hydraulic tilting arrangements. Epoxy Putty Plastic of all kinds Rubber Solutions Chewing Gum Soap Tooth Paste Varnishes Adhesives Ceramic Compounds Colours Explosives Carbon Brushes Brake Lining Carbon Synthetic fibres Artificial Leather

...more

Shrink Packing Machine

We are professionally managed company engaged in manufacturer of shrink tubes. It is manufactured with its precision engineers team & highly sophisticated plant & machinery having closed accuracy of process parameters which meets Global standard. Advantages Griptight shrinkage. Pilfer proof & Tamper evident. Protects from rain, dust, moisture & humidity. Gives an attractive look & presentability Prolonged shelf life. Perfect adaptability to wide variety of shapes & sizes. Exceptional strength makes them ideal for multipurpose promotions. Even used as label

...more

Semi Automatic Label Gumming Machine

A most versatile which makes hand labelling clean and neat. Designed to apply an even coat of adhesive on labels stacked infront of the roller stand and hand fed for gumming. The machine can take up lables of any shape but, the size of the lable is limited to the size of the roller. Machine offered in three sizes viz.5" or 9" roller and 12" driven by an electric motor of 1/6 H.P. and ¼ H.P. respectively.

...more

Rotary Bottle Washing Machine

Emkay ROTARY BOTTLE WASHING M/c (Special model syring type with ISI MARK 1HP /3 PHASE STANDARD MOTOR, starter, a set of 24 rinsers, mounted on m.s. stand, machine all covered with SS-304 sheet, giving an output of 36 bottles per minute.

...more

Ropp Cap Sealing Machine

For cap dia size 22 to 38 mm. With A Rotating Hopper with chute to feed the caps automatically in correct position. Sealing Rollers made of hardened & tenpered steel. Feeding of bottles through a synchronised system of star - wheel with indexing mechanism. Adjustable guide rails to take all sizes of bottles. A Turn Table with independent drive on the incoming side. Main drive with 1.5 H.P. Electric Motor and separate drives for Hopper (.25 h.p.) and Sealing Head Assembly (.33 h.p) Capacity 2,000 to 4,000 bottles per hour. Simple to operate with elegant finish and low cost of maintanance. Inspection Table Inline inspection with independent drive. Incoming bottles bifurcated for 4 operators on opposite direction. Lighting arrangement for visual inspection. Capacity 2,000 to 4,000 bottles per hour. With 1/2 H.P. TEFC type standared make A . C . electric motor provided with rotating head set to ensure perfect and leak proof sealing, suitable hear box drive for wide range of variety and sizes of container, having capacity of cap sizes between 18mm to 70 mm. Adap table for bottle or cans of mamimum 2" to 12" in height and 4" in diameter mounted on heavy duty C.I. stand finished with DUCO paints.

...more

Agitators Reaction Vessels

1. Emkay Reactors are guaranteed for 12 months from the date of commissioning and 18 months from the date of supply whichever is earlier Emkay Engineers provide two free visits to check operation & maintenance of reactors. 2. Emkay Reactors are multipurpose range of reactors filled with Ancher impeller or Turbine blades to suit requirements of Paints, food, Pharmaceuticals, Paper, Distillery units etc. 3. Above technical data is a guide to the users of Reactors. Detailed design & engineering of the reactors must be rechecked by the manufacturer.

...more

PVC Compounding Mixer

high speed compound mixers are high speed mixers use to mix solid to liquid and pasty components. It is simple physical mixers where the heat generated due to friction is utilised for mixing & hence known as "hot mixing". The material may be sintered, agglomerated, dired, degassed or hot coloured. Optimum setting of charge path and mixing process. Self clicking & sealed housing design to avoid material infilteration to bearings most efficient v belt drive with motor sliding device to give highest performance and easy installation of belts.

...more

powder and mass mixer

Suitable to mix dry and wet material. The mixer has all contact parts made out of 304 quality stainless steel with two mechanical seal ends to prevent outside lubricants from entering into mixing chamber.The Paddles of 3/8" thick on the shaft are so arranged as to give thoroughly and uniform mixing. A transparent acrylic cover with S.S. frame is provided for visual observations. The Unit is supplied with tilting arrangement, reversible switch & safety lock-sitch to stop the machine as soon as the cover is opened. The drive is through a suitable motor and gear box.

...more

Portable Mechanical Sifter

his machine is suitable for shifting the granules and the powder. The machine is provided with a stainless steel screen of 20" dia. The unit is friven by 1,5,H.P. vertical motor. The screen frame and discharge chute etc. are made out stainless steel . The unit does not require any foundation and is provided with heavy castor whaels for movability .The unit is supplied complete with one s.s sieve of any mash (to be specified while ordering). Extra price for S.S. sieve of any mesh. Applications Chemicals, Pharmaceuticals, dyestuff and pigments, ceramics, food products detergents, cosmetics, pesticides adn fertilizers, paper pulp, resins, paints, polyerter chips, minerals, rubber compounds, slurries, metal, powers.

...more

Planetary Mixer

Suitable for mechanical mixing of ointments. Dry Power or wet mass etc. The unit is provided with stainless steel slow speed mixing stirrer/beater having three speed (i.e.the stirrer shaft will be moving on it's axis as well be rotating round the bowl) for giving efficient mixing. The bowl is provided with castor wheels for easy handling. The unit is supplied wth all stainless steel contact parts having three and four speed mechanism and is driven by means of suitable one tempered gear box, self / splash lubricatin system mounted on heavy duty C.I. body fitted with horse power 3 phase, A.C.operated.

...more

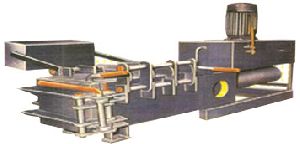

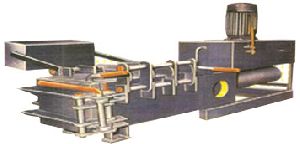

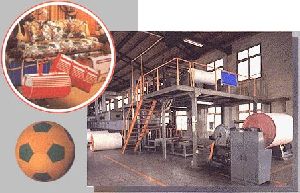

P.V.C. Synthetic Leather Manufacturing Equipment

Synthetic Leather is known by its strength, flexibility, friction resistance and above all physical nature. It is the best use of Baggage, Garments, Footwear, Sports, Furniture, Automobile, Railways, Defance & other industries. The latest invented technology will allow synthetic leather to meet main stream of leather business in future.

...moreBe first to Rate

Rate ThisOpening Hours