copper electroplating

Get Price Quote

Welcome to NK Enterprises, your premier destination for top-quality copper electroplating services in Okhla, Delhi. With a commitment to excellence and a track record of superior craftsmanship, we take pride in offering you unparalleled expertise in the field of metal electroplating. At NK Enterprises, we understand the significance of copper electroplating in enhancing the durability, conductivity, and aesthetics of various products. Our state-of-the-art facility is equipped with cutting-edge technology and staffed by a team of skilled professionals who possess a deep understanding of electroplating processes. With years of experience under our belt, we have established ourselves as a reliable and innovative partner for businesses across various industries. Our copper electroplating process is a meticulous blend of science and artistry. We begin by thoroughly cleaning and preparing the substrate, ensuring that it is free from any impurities that might hinder the plating process. Our experts then apply advanced techniques to ensure uniform and precise deposition of copper onto the surface, resulting in a flawless and consistent finish. What sets NK Enterprises apart is our unwavering dedication to quality and customer satisfaction. We work closely with each client to understand their unique requirements and tailor our electroplating solutions accordingly. Whether you need copper electroplating for decorative purposes, improved conductivity, corrosion resistance, or any other application, we have the expertise to deliver results that exceed your expectations. As a responsible player in the industry, we prioritize environmentally friendly practices. Our electroplating processes are designed to minimize waste and maximize efficiency, while adhering to all relevant safety and environmental regulations. Conveniently located in Okhla, Delhi, NK Enterprises is not only a hub of technical excellence but also a symbol of trust and integrity. Our commitment to delivering outstanding copper electroplating services has earned us a reputation that stands as a testament to our dedication. When you choose NK Enterprises for your copper electroplating needs, you're choosing a partner who values precision, innovation, and customer satisfaction above all else. Join us in transforming your products into shining examples of quality and craftsmanship through the art of copper electroplating.

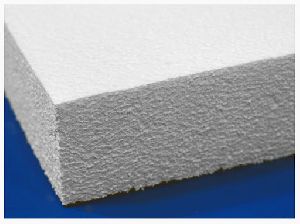

Expanded Polystyrene

Get Price Quote

10 Metric Ton (MOQ)

Expanded Polystyrene EPS is an abbreviation for Expanded Polystyrene. The raw material used for EPS are small polystyrene beads that have been allowed to absorb 4-7 % pentane gas. The pentane gas is what makes the material expand when heated. EPS can expand up to 50 times the original size. This means that the final product contains around 98% air. Most of the pentane gas is released during the manufacturing if EPS and is replaced with air. Released pentane gas will not affect the ozone layer. EPS is suitable for disposable packaging, but is also well suited for technical products with higher density, for example bicycle helmets. EPS can be found in a variety of different colours. Expandability (time): 50-85 Compressive strength: 0.7 kg / cm2 Flexural Strength: 2.5 kg / cm2

Best Deals from Expanded Polystyrene

tin electroplating

Get Price Quote

Tin Electroplating is mostly used for imparting the properties of tin on other metal surfaces. Tin are slowly deposited on the surface of the other metal, hence the process is carried out in a electrolytic solution with a tin sticks. The properties of tin metal are also transferred to that metal surface. Tin electroplating is widely used in the electronics and chemical industries.

Nickel Electroplating

Get Price Quote

Electroless nickel plating is an auto-catalytic reaction used to deposit a coating of nickel on a substrate. Unlike electroplating, it is not necessary to pass an electric current through the solution to form a deposit. This plating technique is to prevent corrosion and wear. EN techniques can also be used to manufacture composite coatings by suspending powder in the bath. Electroless nickel plating has several advantages versus electroplating. Free from flux-density and power supply issues, it provides an even deposit regardless of workpiece geometry, and with the proper pre-plate catalyst, can deposit on non-conductive surfaces.

Nickel Electroplating

Get Price Quote

Magnesuim Acetate, USP, EP, Polysorbate 20 USP, EP, Tromethane, USP

Expanded Polystyrene

Get Price Quote

Expanded Polystyrene, Glasswool, mineral false ceiling tiles

Chrome electroplating

Get Price Quote

Chrome electroplating, black nickel, Nickle Electroplating

grease ep

Get Price Quote

grease ep, Grease, Hydraulic Circulating Oil

Expanded Polystyrene

Get Price Quote

Expanded Polystyrene, Sound Proof Insulation, Resin Bonded Rock Wool

Silver Electroplating

Get Price Quote

Silver Electroplating, Servo Transformer, Electroplating Plating Tank

EPS

Get Price Quote

EPS, PE Foam, Stainless Steel Sheet, Thermocol, poly foam