Round Knife Cloth Cutting Machine

4,500 Per Piece

1 Piece (MOQ)

Gsm Round Cutter

Get Price Quote

In order to known about the GSM (Gram Square Meter) of the textile of any type, GSM Round Cutter should be used. It gives accurate result and is highly cost effective. GSM Round Cutter can be used for virtually any type of material including Film, Foam, Carpet, Paper and Board. We are a notable Manufacturer, Exporter and Supplier of GSM Round Cutter from New Delhi. Our exclusive range of GSM Round Cutter can be purchased from us at market leading prices. Round Cutter : To determine the GSM of the Textiles (Woven, non-Woven or Knitted Fabric) a specialized Instrument is used which is called Round Cutter for GSM. LABIN Round Cutter can be used for virtually any type of material including Film, Foam, Carpet, Paper and Board. Equipment : The Equipment consists of Round Cutter fixed on a Metallic Base having side Locking System. The Cutting Pad is also fixed on the Base Frame. As the Cutter is lifted, it automatically gets locked in the upright position. Now you can place the Fabric conveniently on the Cutting Pad. As you release the Lock, the Cutter gets in the Original Position on the Fabric. The Specimen will cut out neatly and accurately by rotating the Hand wheel.The Round Cutter has four German Blades and the Cutting Pad. The Cutting Pad is a special type of Pad, which takes just any kind of Fabric. The Blades are reversible type. When Blade's one side gets rough by using, the Blade can be turned to the other side. Turning to other side can use all the four sides of the Blade.The GSM Round Cutter is recommended for yield Testing i.e. the determination of weight per unit area. The Sample Cutter cuts out rapidly and accurately circular specimens of 100 cm², which is exactly one hundredth of square meter, the result in grams, multiplied by 100, gives us grams per square meter.Calculation : Grams per Square Meter = Specimen Weight in Grams x 100The Equipment is supplied with : Round Cutter along with Side Locking System on a sturdy Base Frame. One extra Cutting Pad. P. S .: The only parts to be replaced, with the use of the Round Cutter, is Blades and the Cutting Pad.

Best Deals from Fabric Cutters

Gsm Round Cutter

Get Price Quote

We are offering GSM Round Cutter to determine the GSM of the textiles (woven, non-woven or knitted fabric). It is a specialized instrument which is called round cutter for GSM. Our GSM Round Cutter can be used for virtually any type of material including film, foam, carpet, paper and board.EquipmentThe Equipment consists of Round Cutter fixed on a Metallic Base having side Locking System. The Cutting Pad is also fixed on the Base Frame. As the Cutter is lifted, it automatically gets locked in the upright position. Now you can place the Fabric conveniently on the Cutting Pad. As you release the Lock, the Cutter gets in the Original Position on the Fabric. The Specimen will cut out neatly and accurately by rotating the Hand wheel. The Round Cutter has four German Blades and the Cutting Pad. The Cutting Pad is a special type of Pad, which takes just any kind of Fabric. The Blades are reversible type. When Blade's one side gets rough by using, the Blade can be turned to the other side. Turning to other side can use all the four sides of the Blade.The GSM Round Cutter is recommended for yield testing i.e. the determination of weight per unit area. The Sample Cutter cuts out rapidly and accurately circular specimens of 100 cm2, which is exactly one hundredth of square meter, the result in grammes, multiplied by 100, gives us grammes per sqaure meter.The Equipment is supplied with : Round Cutter along with Side Locking System on a sturdy Base Frame.

Rotary Die Cutter

Get Price Quote

Chain Feed. The rubber roller adopts mechanical control the position move left and right. The movement distance is 40mm The die-cutting phase adopt electric 360 adjusting, accord the error to input the adjust data, can be adjusted while the machine running or stop. The space adjustment between rubber roller and die roller adopt self locking structure, with cylinder big scope quickly adjust, decrease the rubber wear, increase the rubber life. The space adjustment between the feed rollers adopts self locking structure. The unique speed compensation device can make the rubber roller rolling running with the die roller, make the surface speed of the rubber cushion is completely controlled equal to the die pattern. There is a rubber repair device with the machine, the rubber can be used after be repaired

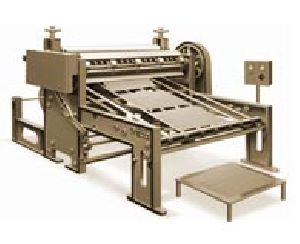

Rotary Sheet Cutter

Get Price Quote

This machine is used to cut Kraft Liner Paper or 2 Ply Corrugated Board into sheets without damaging the flutes (In the case of Corrugated Board). It can be used independently as well as an attachment to the single facer in order to facilitate accurate sheet cutting process. Fitted with Oil Lubrication Pump (OLP) in order to provide continuous and consistent supply of oil to the Gear system of the machine Comprehensive feature of the machine is the Excel Make PIV Gear Box fitted with imported chain in order to adjust the sheet size to be cut with respect to the Gear Ratio. Perfect Synchronisation of the machine and Single facer, with the provision of AC Drive. Improved Cutting Process with Four Edge cutting. Delivery Conveyor in order to stack Cut Sheets

Ultrasonic Fabric Cutter

185,000 Per

Rotary Sheet Cutter

Get Price Quote

This machine is designed for high production and straight cutting of sheet or two ply corugated board without damaging flutes and linear paper. This machine can also be synchronized directly with corrugation machine. PIV chain gear box is provided for adjusting cutting length of sheet (18" to 100").Maximum Speed Is 250 Feet per Minute Apprx.

Cloth Cutting Machine

Get Price Quote

fabric laser cutting machine

Get Price Quote

Features : Selection of track-type work platform, with automatic feeding system, continuous processing can be automated, and equipped with intelligent layout software, processing speed, material saving, making, revision convenient, cutting, high efficiency, good quality, especially for the patch embroidery fabric cut pieces. An optional cellular zinc, iron working platform and a single laser head. The latest software and AutoCAD, CORELDRAW and other design software for seamless : Direct Original output function, support any variety of colors, free to define the sequence of cutting or carving, easy to achieve all or part of a graphical output. Three-and six balanced to reflect the system outside the sliding rail is: the trajectory of the knife and run more smoothly, to ensure that the cutting, sculpture, efficiency and accuracy. Specially designed tube, cut a small slit, short-focus telephoto lens replacement easy USB interface, store up to 512t11 file, run offline Rewind drawer and funnel design for easy rewinding. Improve efficiency By Industry - Clothing, shoes, bags, computer embroidery cutting, and other industries. Application materials - Application materials - This applies to goods, paper, leather,. fabric, non-woven, silk, wool, and other materials.