Mineral Water Bottling Plant

We are well-equipped to undertake turnkey projects for establishing mineral water plants Our integrated solutions fulfill complete requirements requiring for purifying water bottling purified water and labeling The mineral water plants are designed for minimum economically viable capacity We design our plant according to the norms of government agencies So that there must not be any issues regarding abiding of law We also help in getting approval from govt Body Our plants are available in different specifications and capacities We do the complete set-up of labs with all the equipments necessary for lab like glass-ware chemicals analysis instruments etc

Industrial Reverse Osmosis Plant

105,000 Per Piece

Type : Industrial Reverse Osmosis Plant

Application : Water Purifies

Weight : 1000-2000kg

Color : Blue

Voltage : 220V

Condition : New

Automatic Grade : Fully Automatic

Power : 12-15kw

Driven Type : Electric

Warranty : 1year

Country of Origin : India

Brand Name : GWT

Material : FRP/SS

Capacity : 1000LPH

Motor : 2HP

Water Treatment Plant

115,000 Per Piece

Inlet Flow Rate (cubic meter/hour) : 1000, 1000 m3/hour

Applicable Industry : Food and beverage sector, Hotels, Residential complexes

Application : Sewage Treatment

Automatic Grade : Manual

Condition : New

Features : Bolt free, completely impermeable, Energy efficient, Sturdy construction, Simple installation, High performance.

Water Source : Borewell Water

Installation/Civil Work : Installation Available

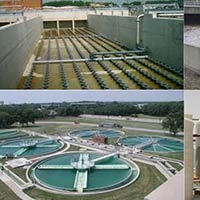

Effluent Water Treatment Plant

Also known as Industrial Wastewater Plant, this Effluent Water Treatment Plant is known for the adoption of cutting-edge purification technologies. Sources of industrial wastewater include manufacturing, commercial businesses, mining, agricultural production and processing, and wastewater from cleanup of petroleum and chemical contaminated sites. Industrial wastewater discharged under CPCB and NPDES permits may be subject to federal Effluent Limitations Guidelines (ELG). In addition, all industrial wastewater discharges must provide reasonable assurance of meeting water quality standards for surface water or ground water in order to receive a discharge permit. We are synonymous with long-term experience in the Effluent Water Treatment Plant. The resulting expertise is advantageously employed for the technical and economic optimization of every subsequent facility. The treatment process adopted by the Effluent Water Treatment Plant contains mechanical, biological and chemical physical process steps. Following Processes Are Used : Aerobic biological processes Anaerobic biological processes Physical-chemical process Electro-coagulation Aerobic biological processes of the Effluent Water Treatment Plant are designed to meet differing purification demands, which relate specifically to the effluent to be treated. As a rule, the concentrations of organic and inorganic substances in industrial wastewater are considerably higher than those found in the municipal sector. In the biological wastewater treatment segment, we can supply both aerobic (with oxygen) and anaerobic (without oxygen) processes and thus furnish optimum solutions for individual requirements. It is often the case that both processes are combined in order to achieve the highest possible purity levels in the treated wastewater. Also, we have technologies, which allow the cleaning of wastewater containing compounds that are difficult to degrade. Among others, the following processes are employed by our Effluent Water Treatment Plant : Activated sludge process Submerged aerated fixed films Moving bed bioreactor Sequencing batch reactor

Solar Light

1,500 Per Piece

Type : Solar Light

Certification : ISO 9001:2008

Application : Domestic, Home

Color : Blue, Green, Red, White, Yellow

Specification : Battery Management System, Bright Light, Light Weight, Mini Size, Motion Sensor Based Auto Dimming, Normal Size

Warranty : 1year, 2years

Water Softening Plant.

Water Softening Plant The Ionberg Industrial water Softeners is a manually or Automatically operated ion exchange unit designed specially for industrial use. It is simple to operate, inexpensive to maintain and is widely used in the industry. The softener comprises Steel FRP pressure vessels containing a bed of cation exchange resin, a regenerating system and control valves. A strongly acidic cation exchange resin in sodium form is used to exchange sodium ions for the hardness –forming calcium and magnesium ions, and thus produce soft water . At the end of each service cycle, the ion exchange resin is regenerated with sodium chloride solution, after which the units is ready for the next service cycle. For larger plants, a brine measuring tank is provided, and a separate salt saturator, preferably in concrete, is recommended for bulk storage of salt and preparation of brine. Standard equipments is available to soften water, upto a maximum flow rate of 100 m3hr. Salient Features Softeners are attractive, compact, easy to operate. Maintain, & use international quality materials of construction. Softeners are available in Mild Steel, MS Rubber Lined, FRP, operating in Manual Auto mode. Single Lever Multiport Valve or Diaphragm Valves along with CPVC MS piping flexibility. Technical Features Mild Steel FRP pressure vessels provided with an inlet distribution, an outlet collecting system and a brine distributor. Mild Steel vessels is painted externally with a protective coat of red oxide and internally with anti-corrosive bituminous paint. Set of control valves, with all piping to inlet and outlet terminals. Combined salt tankbrine measuring tank, provided with brine suction piping with adjustable indicating clamps, hydraulic ejector and control valves. Charge of softener cat ion exchange resin with supporting under bed. Hardness test kit for testing the softened water.

Milk Pouch Filling Machines

Min. Order Quantity : ,

We are counted among the renowned Fabricators and Suppliers of Milk Pouch Filling Machines in Delhi. The Milk Pouch Filling Machines are known for their efficiency. The Milk Pouch Filling Machines are made using quality raw materials and provide optimum performance. The Milk Pouch Filling Machines are available at highly competitive prices. Highlights Of Milk Pouch Filling Machines High durability Safe packing Energy saver Precision engineering Smooth performance Quick working without errors

Water Softening System

Water Treatment Plant

Waste Water Treatment Plants

Wastewater Treatment Plants