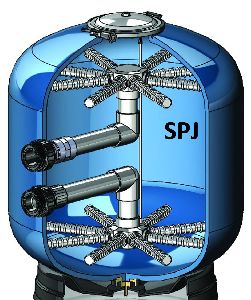

Swimming Pool Filter System

65,000 - 980,000 Per Set

1 Set (MOQ)

We are a manufacturer, supplier and exporter of swimming pool filteran system amd all related equipments of pool filter and other accessories.

Bag Filter System

Get Price Quote

1 Piece (MOQ)

Best Deals from Filter System

Pressure Sand Filter System

Get Price Quote

1 Piece (MOQ)

ULTRA VIOLET SYSTEM

Get Price Quote

MFP filter test rigs system

Get Price Quote

With the MFP series, Palas® offers high-precision testing systems for the development and quality control of filter media. From HEPA qualities with high separating efficiency to pre-filtering qualities, the test rigs in the MFP series deliver clear, fast and therefore cost-effective testing results. Based on the test requirements specified in standards like EN779, ASHRAE 52.2, DIN 71460-1, ISO TS 11155-1, ISO 5011, EN 1822, ISO 29463 or based on special practical requirements, the MFP test rigs are equipped with different systems for aerosol generation, electrical discharge of aerosols, aerosol dilution and air humidifiers. The clear determination of the fraction separation efficiency is performed highly accurately using the aerosol spectrometers Promo® 1000, 2000 and 3000. The wide range of interchangeable welas® sensors allows the measuring system to be perfectly fine-tuned even for particle concentrations up to 1 gm3 with SAE dust in accordance with ISO 12103-1.

jet filter cage systems

1,000 - 10,000 Per Piece

10 Piece(s) (MOQ)

Explore everything you need to know about JET FILTER CAGE systems in this comprehensive guide. Learn about their installation, benefits, and how they enhance the efficiency of your dust collection system. Whether you're in industrial manufacturing, food processing, or any other industry requiring dust filtration, our JET FILTER CAGE solutions provide superior performance and durability. Don't miss out on this essential information for maintaining a clean and safe work environment. JET FILTER CAGE, Jet Filter Cage installation, Jet Filter Cage benefits, dust collection system, industrial dust filtration, filter cage, filter bag cage, pulse jet filter, filter cage maintenance, dust filtration solutions, industrial filter cage

Industrial Ultra Filter System

Get Price Quote

We at A3 Techno Crafts provide fully automated systems for filtration of surface or well water. Performance: 3 to 48 m3/h or 70 to 1100 m3/day plant.Ultrafiltration allows in many cases the utilization of alternative raw water instead of precious tap water. The use of surface water or ETP water therefore saves cost and protects the environment.With a wide range of optimized UF systems, we are a strong partner for you in all ultrafiltration applications.We will be happy to support you on ultrafiltration solutions and discuss potential savings and ROI based on your project data. Very short payback period, usually

Cartridge Filter System

70,000 Per Piece

Bag Filter Systems

Get Price Quote

Membrane Filtration Assembly

Get Price Quote

Applications :High product recovery under negative pressure. For superfine filtration.

Cartridge Filter System

Get Price Quote

Cartridge Filter System, a revolutionary concept, changed the way filter systems performed. The usual limitations to the filtration efficiencies offered by conventional bag filter systems and the related maintenance problems suddenly vanished. SANTONI was the first to introduce Cartridge Air Filters technology into India. While assimilating this state-of-the-art technology special care was given to the Indian conditions and the specific requirements of the industry. Santoni is also renowned among the most famed Industrial Cartridge Filters Manufacturers in India. Some of the benefits offered by SANTONI�s Cartridge Filter Systems are outlined below: Compared to a conventional bag filter that offers a maximum of 99% efficiency for particle range down to 7 microns, cartridge filter systems can filter up to 99.97% down to 1 micron. (Now we have cartridges which can filter down to 0.3 microns too). Cartridge Elements in a cartridge filter system are built out of fine paper filter media arranged in a pleated manner, due to which a very large filter area is accommodated in a very small cylindrical shape. The net effect is that a cartridge filter system occupies much smaller area and space compared to a conventional bag filter system. Typically the space required for a cartridge filter system is about one eighth the volume required by a bag filter system. The architecture of the cartridge filter system is designed in such a way that servicing or replacement of filters takes just a few minutes and can be carried out by one person, unlike a bag filter system which requires up to several days to open and replace filters. The cartridge filter systems are offered by SANTONI in two configurations - horizontal and vertical. The "Gravityflo" downward air movement within the filter system allows natural gravity separation of the dust from the air and the downward air pattern pushes the dust down into the collection hopper rather than letting it go towards the filters. This reduces the filter loading considerably. The dust dislodged by the reverse pulse filter cleaning system is also pushed down. This obviates re-entrainment of the dust into the filters. The filters are continuously cleaned with reverse air blasts controlled by an electronic sequential controller. The filter system remains continuously operative at its peak efficiency. The typical life span of the cartridge filters is two to two and half times the bag filters. It makes the cartridge filter systems far more economical too. APPLICATIONS Cartridge Filter Systems (CFS) have several applications - such as, Dust collection, pneumatic conveying, central vacuum cleaning systems, etc.Because of their capability to provide exceptionally high degree of filtration CFSs are of particular use where toxic materials or materials of high value (e.g. gold dust) are handled.In the industries where cleanliness of high order is expected (e.g. clean room applications), CFSs are used in the dust collections and pneumatic conveying applications.In the tissue culture, aquaculture, pharmaceutical, chemical, pesticide, premium sugar, decorative laminates, printed circuit boards, diffusion labs, etc. the dust has to be eliminated and only CFSs meet the requirement.For powder coating paints - in their manufacturing or painting process - CFSs are very useful. After pulverizing in a mill the powder paint has to be removed and collected pneumatically, at the end of which a CFS can collect all the paint. Similarly, paint can be recovered efficiently in the painting process. A special benefit that CFSs offer is the quick change-over when the color is to be changed.Similarly, in the pesticides industry, toxic materials are pulverized which should be handled only with the help of CFSs, to prevent pollution of environment and exposure of the workers with the toxic materials.In the coated paper industry, where high quality paper is manufactured, presence of dust in the environment can be detrimental to the quality of the end product. Collection of dust from the buff rolls (cotton bowls) with cartridge filter systems prevents re-entrainment of the dust into the atmosphere.In the nut shell it will be worthwhile to say that cartridge filter systems offer greater filtration efficiency, at reduced cost and, therefore, are a better choice where the dust has to be completely removed or recovered. SANTONI offers these state-of-the-art filter systems at most economical prices.

Bag Filter System

Get Price Quote

Bag filter system are very economical and suitable for applications that generate course dusts – for example saw dust and wood shavings.Closed Bag Filter System – bags are enclosed in a chamber – can be installed outdoors too.

ULTRA VIOLET SYSTEM

Get Price Quote

We are instrumental in providing finest quality Ultra Violet System, which we develop and design in our manufacturing unit. Our team of highly skilled engineers develop new technology based ultra violet system that is useful in cleaning water by removing dust, killing bacteria & virus, and other pathogens by using UV rays. They rays will pass through the water and make it free from harmful elements. We provide custom specifications based ultra violet systems to our customers according to their demands. We ensure perfect look, automatic functionality and high-grade water cleaning results by using ultra-violet systems designed by us. Features: Modern design Good construction Better functionality High level water cleaning Use latest technology & UV rays Easy-to-install

Under Sink Water Filter System

1,500 Per Piece

Filter and Scale Inhibition System

Get Price Quote

BAG IN BAG OUT FILTER SYSTEM

Get Price Quote

Bag in Bag Out Filter System provide a wide performance for preventing the workers from bio-hazard organisms and viruses while they are doing the regular HEPA or ULPA filter replacement work. It is the most effective equipment available for any zone, needing a special critical filtration cleanliness level and negative pressure environment. Bag in Bag Out Filtration System includes pre-filter (and maintenance access door), HEPA or ULPA filter (and maintenance access door), inlet & outlet connecting duct flange unit, frame and mounting bracket. The equipment is full welded with argon welding except maintenance access door. It can be made not only at workshop but on site also. Magnehelic gauge becomes standard for pre-filter, and ULPA or HEPA filter. The housing is made from either T304 12 & 14-gauge stainless steel or optional T316 12 & 14-gauge stainless steel. The locking trays are made from T304 12-gauge stainless steel or optional T316 12-gauge stainless steel. Retrieval rods ease the removal of filters. Seam welding reinforces strength and prevents leakage. Door(s) have perimeter gasket in order to ensure a positive seal. Door knobs are cast aluminum. Inside each unit’s door(s), a ribbed inlet collar provides for a PVC bag attachment. The PVC bag creates a barrier seal between service personnel and the contaminated filters. With this design, filter-servicing personnel are not in direct contact with any threatening particulate. An initial bag kit is included with each order. Depending on end user requirements, a variety of prefilter, adsorber, and/or HEPA filter sections are incorporated into the unit. Housings may be joined in series or parallel. Test sections in series may also be incorporated with the housing. Specific fan filter combinations are also available for isolation room systems.

Mechanical Bag Filter System

Get Price Quote

These systems are used for coarse particles like saw dust & wooden shaving. Open bag filter systems can be used indoors, while closed bag filter systems are used outdoors.

Bag Filter System

Get Price Quote

Features : Economically Designed Low Maintenance Low Operative Cost Low pressure drop High Collecting Efficiency

pulse jet bag filter system

Get Price Quote

We offer Pulse Jet Bag Filter System, which are fabricated using quality tested raw material. These are mainly used for extraction and collection of fine & coarse dust particles from different processes such as chemical, grinding, buffing, polishing, wood dust, pulverizing, and packing. Features: Optimum performance Robust construction Low maintenance Durable

reverse osmosis water filter systems

Get Price Quote

reverse osmosis water filter systems, Water Filter, RO Maintenance, Ro Plant

water filter system

Get Price Quote

water filter system, Kitchen Appliances Mini Flour Mill, Mineral Water System

Water Filter Purifier RO Systems

Get Price Quote

Water Filter Purifier RO Systems, Grand RO System, Hard Water Softeners

Portable Filter Systems

Get Price Quote

Portable Filter Systems, portable hydrogen purity analyzer

Oil Mist Filter System

Get Price Quote

Oil Mist Filter System

water filters systems

Get Price Quote

water filters systems

filter system

Get Price Quote

filter system, Centrifugal Motor Pump, Filtration Plant, designer bath tub

water filter system

Get Price Quote

water filter system, reverse osmosis water filter

water filter system

Get Price Quote

water filter system

Cartridge Filters Systems

Get Price Quote

Cartridge Filters Systems, Corrosion Analysis Services

whirler

Get Price Quote

whirler, Plate Graining Machine, Plate Coating Whirler, lining up table