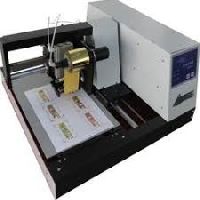

hot foil printing machine

Get Price Quote

Hot Foil Stamper is a programmable controller intended to control the Hot Foil stamping machines. It can control three motors with independent parameter setting for each like motor speed, acceleration; steps per mm etc are independently configurable. 20x4 alphanumeric LCD for settings and status display. Easy to use menus and smooth navigation. 16-bit controller with 32-bit math for precision. Opto-isolated pulse input for easy connection to external signal. Configurable micro-step settings. Low Jitter pulse train on three motor outputs simultaneously.

Aluminum Foil Container Making Machine

Get Price Quote

Aluminum Foil Container Making Machine is a product with the auto-lubricated feeder and length controller and has 145 pneumatic punches. The operational safety is ensured. The features like high rigidity and reasonable strength is due to the use of holistic steel in the product. For satisfactory customer performance, an option can be availed by changing the electrical steeping by PLC controller by us. Based in Delhi, India, we are the leading manufacturer, exporter and supplier of the product. It adopts the electrical stepping system (can be replaced by PLC controller as customer’s requirement) to realize the function of positive and negative rotary of motor. With the adoption of double electromagnetism valves and pressure relay, the operational safety is guaranteed. The frames of equipments are made of the holistic steel which has the advantages of high rigidity and reasonable structure. With the adoption of dry friction clutch, the slide area can stop instantly at any height. And the punch can realize the function of single-stroke, inching motion and continuous action, which is beneficial to regulate the mould position and improve the processing precision. As customers’ requirement, the electrical stepping system can be replaced by a PLC controller, which work better. It also can adopt the light screen protective device, so it is a safe press. Thanks to inside installation of driving system, the layout of the equipment is compact. This production line adopts the independent removable panel which is colorful, convenient and has nice layout Specification of DYSL-520 Auto Lubricated Feeder : Max. Material Roll Dia. : 650m Max. Material Roll Width : 500mm Feeding Speed : 10-30M/min Feeding Length : 30-900mm Feeding Tolerance : +/-0.3mm Capacity : 1Kw Voltage : 380V/220V Weight : 0.6Tons DY-45T Pneumatic Punch : Pressure : 450KN Hole Size of Worktable : 300*300mm Production Output : 40-70times/min Board Thickness of Worktable : 50mm Adjusted Height of Die Setting : 60 mm Size of Screw Hole of Mould : φ50*60mm Size of Worktable : 660*1000 mm*50 mm Dimension : 1500*1125*2315mm (L*W*H) Motor Capacity : 5.5KW Weight : 4Tons Voltage : 3-380v 50Hz

Best Deals from Foiling Machine

Silver Foil Container Machine

Get Price Quote

Silver Foil Container Machine, eps disposable plates

Silver Foil Container Making Machine

Get Price Quote

Silver Foil Container Making Machine, napkin making machine

foil sealers

Get Price Quote

foil sealers, Vacuum Packing Machine, Shrink Wrapping Machine