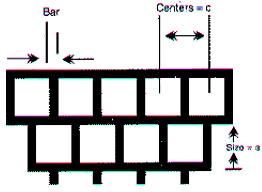

Square Holes

We offer square holes. Square holes are principally used for grills and machine guards offering a maximum of open area to permit good visibility and through-put while providing the necessary protection or decorative cover. Available in both straight line and staggered patterns, the straight pattern is standard for square holes. Both variations are weaker than the round patterns. The sharp corners on the square hole tooling makes it more subject to wear and vulnerable to the stresses of the punching process, increasing tooling costs and reducing production rates. Square hole patterns are generally more expensive than the equivalent round.

...more

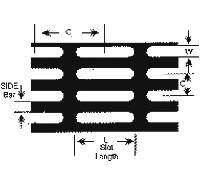

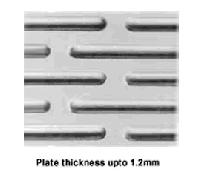

slots

We offer slots. Slots in the side staggered, end staggered and straight line arrangements , are particularly well suited to sorting and grading of solid objects. Typical applications include the sizing of ball bearings or the separation of fingerlings at fish hatcheries.

...more

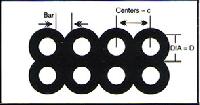

Round Holes

We offer round holes ranging from under 0.6mm to over 75mm account for 80% of the production of the perforating industry. Round holes can be produced with greater efficiency and less expenses than any other hole shape. The dies and punches to make round holes are the most cost efficient to build & maintain. Round holes are the most versatile in their application, providing a wide range of open area and handsome appearance. 60 degree staggered round hole pattern is the most popular hole arrangement because of its inherent strength and the wide range of open areas it provides. 45 degree staggered round hole pattern is stronger than straight row patterns it is not as strong as 60 degree staggered arrangement, nor is it as versatile in providing compact hole spacing & high open areas as the 60 degree arrangemen.

...more

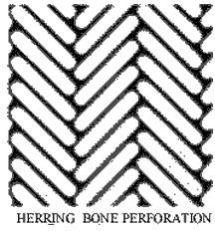

herring bone

We are offering herring bone.

Dimple Holes

we are offering Dimple HolesEmbossed.

Laundry Equipment

Perforated Sheets

Metal Sheets

Be first to Rate

Rate ThisOpening Hours