Mild Steel Laboratory Ball Mill

Application : Industrial

Type : Ball Mill

Material : Mild Steel

Capacity : Upto 1 Kg

Power Source : Electric

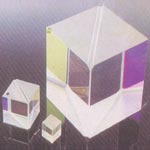

Beam Splitters

Material : Optical Glass

Application : Laboratory

Frequency : 50-60 Hz

Color : White

Voltage : 220-440 V

Pack Type : Box

Our Beam Splitters are designed to separate a single beam of light into two beams that are identical to each other. We specifically coat our Polarizing Beam Splitters to increase the intensity of the separated beams. Cube Beam Splitters we provide are made with hybrid coatings to ensure there is no alteration over a broad range of polarization and wavelength. Towing to the superior quality of our Beam Splitters, we are counted as one of the well reckoned Cube Beam Splitters Manufacturers, based in India.

Auto Suction Hammer Mills

Rotary feeder is supplied with gear box. The Techno Wings hammer mills comprises of a heavy duty Mild Steel fabricated body (alternatively stainless steel construction can be provided in hammer mill wherever necessary). The grinding chamber of hammer mill is lined with serrated wear plates, which protects the body from wear and tear. A dynamically balanced rotor in hammer mill with a set of swing hammers accelerates the grinding process. The screen classifier forms the lower half of the grinding chamber of hammer mill. The blower in hammer mill is driven on a separate shaft with the help of a ‘v’ belt adjustable driven from the rotor shaft.

Bottom discharge hammer mills

Operating Principle of Gravity Hammer Mill The materials to be ground into the crushing chamber of hammer mill from feed hopper by gravity or through an auto feeder (optional) the beaters / blades inside the crushing chamber accelerate the material to a very high speed to the toothed liner placed at the upper half of the crushing chamber. Shearing pulverizes the material. The ground materials continuously discharge through screens placed at the bottom periphery of the crushing chamber and excess air filtered through a cotton balloon. Particle size varied using screens with different size holes. Typical Application of Gravity Hammer Mill Hammer Mills are exclusively meant for the grinding of sugar, bangle grams, maize, pulses, et cetera Outstanding Features of Gravity Hammer Mill Easy to change screens in a variety of sizes Four-way reversible hammers / blades Hinged door for easy access to hammer mill interior Cold & silent running Dust free operations Robust Construction Low Specific Power Consumption Durable Long Life Low Temperature Rise for Heat Sensitive Materials Standard Accessories of Gravity Hammer Mill Motor Pulley 1 Number cotton balloon Anti-vibrating foundation Stand with adjustable rail for motor 3 numbers of perforated round hole screens Extra Accessories of Gravity Hammer Mill Suitable totally enclosed fan cooled single/three phase squirrel cage motor {Electricity (Special power can be accommodated): 110/220/380/415 Volts, 50/60 Hz, 1/3 Phase } Starters, main switch, ampere meter, capacitor for three phase or Miniature Circuit Breaker, ampere meter, for single phase Foundation bolts V Belts All contacting parts stainless steel 304 / 316 can be accommodated

Ball Grinding Mill

Type : Ball Grinding Mill

Certification : CE Certified

Color : Black, Grey, Light White, Yellow

Driven Type : Electric

Laboratory Ball Mills

Material : Stainless Steel

Application : Industrial

Voltage : 220 V to 420 V

Power Source : Electric

Automation Grade : Automatic

Frequency : 50-60 Hz

Fused Splitter