Drilling Machine

Get Price Quote

With our rich industry experience, we manufacture, trade, distribute, wholesale and supply an extensive range of Ultrasonic Drilling Machine that is widely used drilling purpose. Our offered drilling machine is manufactured using premium quality components and modern technology in line with industry standards. Furthermore, this drilling machine is available in different technical specifications and sizes as per the requirements of the clients. Appreciated for its reliability, high strength and durability, this drilling machine is demanded in the market. Features: Low power consumption Easy usage Smooth functioning Other Details: Ultrasonic drilling machine is a device in which a method of brittle destruction by collision of abrasives is forced against a work by an ultrasonically vibrated tool assisted by an appropriate clamping force The tool vibration can be of amplitude approx Ultrasonic Vibrations run perpendicular/vertical on the work piece and drill/embosses precisely.

PRO-62 Annular Cutter Drilling Machine

108,000 Per Piece

The PRO-62 annular cutter drilling machine is equipped with 19 mm (3/4”) Weldon tool holder uses TCT and HSS annular cutters. Strong motor enables cutting capacity up to 65 mm (2-9/16”) and depth of cut up to 75 mm (3”). Dual bars guide system ensures extraordinary stiffness and adjustment free operation. Notable Features: Rigid casting prolonging the tool life The motor auto-stops when brushes are worn out (replace the brushes to restart the motor) Innovative smart magnet with reduced weight Large capacity coolant container, for more holes without re-fill Energy Saving Base (ESB) uses only 50% of its power when motor is not running Magnetic Field Shape Control (MFSC) provides maximum holding power on thin materials Magnetic Power Adhesion Control (MPAC) detects adhesive force of electromagnetic base and protects both the machine and the operator from work on too thin work piece

Best Deals from Heavy Drilling Machine

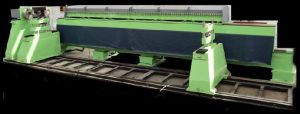

multi drilling machine

Get Price Quote

Zenith has designed its high performance Multi Drilling Machine for Drilling holes in Suction and Blind Drill rolls. These rollers are extensively used in paper mills all over the world as they are more efficient in draining of water than any other technique. Today most of the Paper manufacturing Companies across the world is using Blind Drill Rollers and we think that every paper mill roller manufacturer must have this machine to be able to manufacture such Rollers. Some of the salient features of the Machine are as follows :- Fully automatic with PLC controlled. Capable of drilling holes in rollers upto 8 to 10 meters as per standard. ( the drilling length can be increased or decreased as per requirement) Working diameter upto 1800mm Capable of drilling holes upto 3 - 5 mm diameter in size. The depth of the drilled holes is upto 6 -10mm as per standard. However the drilling depth can be increased if required. There are 175 drills to 300 in one line. Additional drills can be added if required. Roller with diameter 1800 mm can be drilled in 10 to 12 hour time. Roller weight carrying capacity upto 50 tons Power required to run this machine is about 30HP/ 22 kW

Core Drilling Machine

Get Price Quote

Suitable to cutdrill cores of Concrete, Rocks, Stones, Tiles or the similar material. The machine is suitable for core samples of size upto 150mm diameter with the help of thin walled Diamonds Bits which are extra cost. The machine has sturdy base with pillar support in which rack and pinion is provided for adjustments in height and penetration assembly. The leveling screws are provided at the base. For gripping the sample in position suitable grips are provided. a suitable electric motor, standard make is fitted in the machine with cooling arrangement with water. the base frame is also fitted with wheels for ease of transportation.

Vertical Core Drilling Machine

Get Price Quote

We are offering core drilling machine are light weight & compact size. It is work with 220v motor fitted at the top . The screw is provide at the bottom for the fixing at the site. high strength gear is provided for the long life. It has good speed for fast working. the core bit is also supplied with the machine. it is ideal used in the concrete, bitumen, reinforced concrete, brick in construction.

drill grinding machine

Get Price Quote

Double Ended Pedestal Grinding Machines are specially designed to provide heavy Metal removal in Engineering Workshops, Factories, Forging units, Foundries etc. Each Pedestal Grinder is complete with Electric Motor, Starter, Two Grinding Wheels, Two M.S. Wheel Guards with exhaust outlets, and two adjustable tool rests. The motor is fitted in the base of the Pedestal Grinder and the machine is equipped with 2 Speed V-Belt Drive. Arrangement is provided for increasing the spindle R.P.M when the Grinding Wheel Diameter is reduced. This helps to maintain the correct surface foot per minute Grinding speed.

Radial Drill Machine

Get Price Quote

crawler drill machine

Get Price Quote

Our high quality range of Crawler Drill Machine raise the quality of rock drilling to a new level. The top hammer crawler is an inexpensive but efficient choice for quarrying and construction works. These crawler drill rigs will help you to drill smarter holes with high shift capacity, low energy consumption, and innovative modules that improve productivity. Atlas Copco and Ingersoll Rand crawler drills are available in various capacities.

Core Drilling Machine

Get Price Quote

Core Cutting/ Core Drilling Machine (Petrol & Diesel Engine) Product Specification: Suitable to cut/drill cores of concrete, rocks, stones, tiles or the similar materials. The machine is suitable for core samples of size upto 150 mm diameter with the help of thin walled diamond bits which are at extra cost.The machine has sturdy base with pillar support in which rack and pinion is provided for adjustment in height and penetration assembly. The leveling screws are provided at the base. For gripping the sample in position suitable grips are provided. A suitable petrol engine is fitted in the machine with cooling arrangement with water. The base frame is also fitted with wheels for ease of transportation. Dimension approx, are as under: Height : 1300 mm Base : 625 x 900 mm Head Travel on rack : 500mm Drill speeds : 900 R.P.M. for soft samples and 350 R.P.M. for hard Samples Water swivel : Built in the machines. Accessories : Thin wall diamond bits. Core barrel. Petrol engine 190 cc

Used Radial Drilling Machine

Get Price Quote

We are actively engaged in providing Used Radial Drilling Machine. Our Radial Drilling Machine, even though used, is present in excellent working condition. Matching with the international standards, our Used Radial Drilling Machine ensures excellent performance with low maintenance requirement. Moreover, our Used Radial Drilling Machine models are easy to operate and are known for high drilling efficiency. With such attributes, the cost-effectiveness of the Radial Drilling Machine acts as an add-on for the clients.

Cutting & Drilling Machine

14,000 Per Piece

Paper Drilling Machine

45,000 Per Piece

Pillar Drilling Machine

Get Price Quote

• Main spindle and pinion made from EN steel by forging. • Column, arm, work-head & gears made from finest closed grain cast iron; while spindle Ram trim Alloy steel. • Main spindle run out is checked for accuracy as per IS 2199. • For the smooth sliding of sliding arm, special 'slide-reliever-slots' are given. • All moving parts are fine-finished with grinding to a close tolerance. • International technic of 'Taper wedge setting'. for complete slide-setting instead of normal one point setting. • Quality bearings with grease bath, so for permanent oiling. • Main gear and pulley are perfectly balanced. • Powder coated accessories for longer life and prevention of corrosion and pillage associated with usual chrome plating. • P = Pillar Drill m/c • 19/25/40 = Drilling capacity • S = Square Head Model • R = Round Head Model • L = Long Spindle Travel • A = Autofeed Model • X = Xtra Heavy Model

ultrasonic drilling machine

650,000 Per Piece

Radial Drilling Machine

Get Price Quote

We serve flawless Manufacturing, Exporting, Importing and Supplying a comprehensive range of Radial Drilling Machine. Our Radial Drilling Machines are highly durable and functional. All the raw materials used in the manufacturing of our Radial Drilling Machines are of high quality and heat treated to gain best possible durability. Our clients can avail these machines in different sizes, models as per their requirements. Features Safe & ReliableEasy to operate Main parts are made by machine center which import from KIA with high precision & efficiencyHigh Quality of Spindle Parts UsedHeat Treated DurabilityLow Noise

Drill Machine

Get Price Quote

Horizontal Directional Drilling Machine

Get Price Quote

Radial Drill Machine

Get Price Quote

horizontal drilling machines

Get Price Quote

horizontal drilling machines

Horizontal Directional Drilling Machine

Get Price Quote

Horizontal Directional Drilling Machine, Splicing Machines, blowing machines

drill machinery

Get Price Quote

drill machinery, Hammer, Wood Cutter

geared drilling machine

Get Price Quote

geared drilling machine, Drilling Machine, Tapping Machines

Drill Machine

Get Price Quote

Drill Machine, Armatures, Electric Blower, Electric Power Tools

CNC Gun Drilling Machine

Get Price Quote

CNC Gun Drilling Machine, Cnc Rack Rolling Machine, vertical turret lathes

Wet Rock Drill Machine

Get Price Quote

Wet Rock Drill Machine, Drill Outlet Valve, Cylinder Assembly

Drilling Machine

Get Price Quote

Drilling Machine, Milling Machine

Drilling Machines

Get Price Quote

Drilling Machines, Air Grinder, Vacuum Circuit Breakers, Rock Drill Hose

Drilling Machine

Get Price Quote

Drilling Machine, Clean Room Equipment, Sheet Metal Machine

Drilling Machines

Get Price Quote

Drilling Machines, molding equipment

Drill Machines

Get Price Quote

Drill Machines, Panels